Method for improving bleaching effect of cotton and blended fabrics under multienzyme coupling action

A technology of blended fabrics and fabrics, applied in the field of biological bleaching, which can solve the problems of chemical additives polluting the environment, poor enzyme bleaching effect, and large fiber damage, etc., and achieves the effects of wide adjustable range, wide adjustable space, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

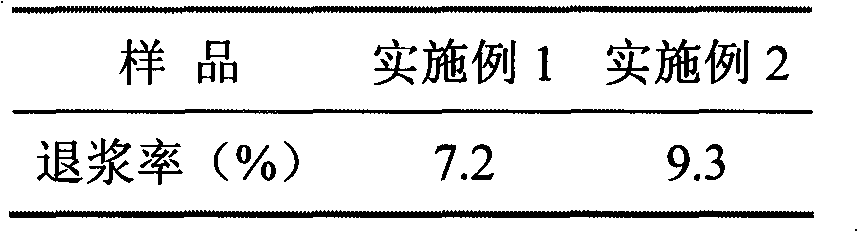

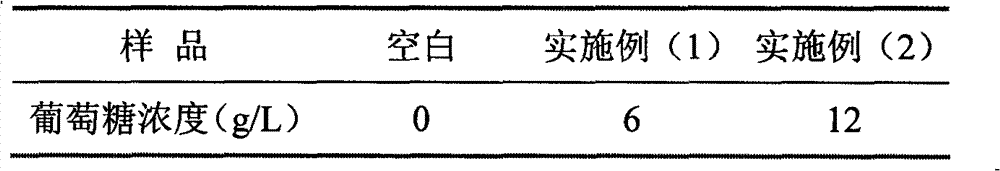

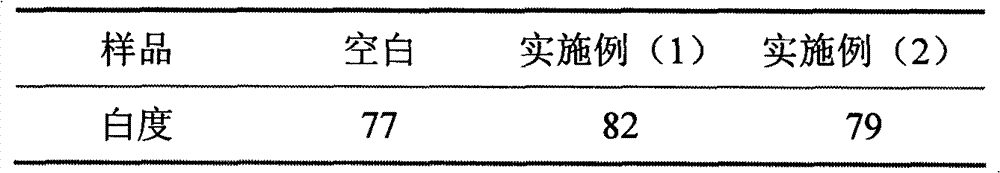

Embodiment 1

[0033]Pre-wash the cotton plain gray fabric (linear density 24.3tex×24.3tex, fabric density 252 / 10cm×231 / 10cm) in a water bath at 80-95°C for 20-30 minutes to ensure sufficient wetting of the fabric; then , put the pre-washed fabric in the treatment solution of amylase and glucoamylase for dipping and desizing treatment. The mass concentration of amylase in the treatment liquid is 1g / L, the mass concentration of glucoamylase is 1g / L, the bath ratio is 1:50, the immersion temperature is 60-70°C, and the immersion time is 1h. After the treatment, take it out, wash it with hot water, wash it with cold water, and dry it in a blast oven at 60°C; finally, use 9g / L glucose oxidase to catalyze the desizing residue, and adjust the pH value of the residue to 10. Bleaching is carried out in the treatment residue with a bath ratio of 1:50, the bleaching temperature is 90° C., and the bleaching time is 1 hour. Take out the water for washing, and dry the finished fabric in a blast oven at ...

Embodiment 2

[0035] Pre-wash the cotton plain gray fabric (linear density 24.3tex×24.3tex, fabric density 252 / 10cm×231 / 10cm) in a water bath at 80-95°C for 20-30 minutes to ensure sufficient wetting of the fabric; then , put the pre-washed fabric in the amylase treatment solution for dipping and desizing treatment. The mass concentration of amylase in the treatment liquid is 1g / L, the bath ratio is 1:50, the soaking temperature is 60-70°C, and the soaking time is 1h. After the treatment, take out the fabric, wash it with hot water and cold water, and dry it in a blast oven at 60°C; then, add 1g / L glucoamylase dropwise to the residual liquid after desizing, and dry it at 60-70°C Treat for 1 hour; finally, use 9g / L glucose oxidase to catalyze the desizing residue treated with glucoamylase, adjust the pH of the residue to 10, and place the fabric in the treatment residue with a bath ratio of 1:50. Bleaching, the bleaching temperature is 90°C, and the bleaching time is 1h. Take out the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com