Frost preventing and removing system and frost preventing and removing method of heat pipe type air conditioner

A technology for an air conditioner and an air conditioner room, which is applied to the defrosting system and the heat pipe type air conditioner defense field, can solve the problems of reducing heat supply, increasing the condensing temperature of the outdoor heat exchanger, and failure of the heat pipe, so as to reduce the frost formation. possibility, the effect of reducing the number of defrosts, delaying the time of frost formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

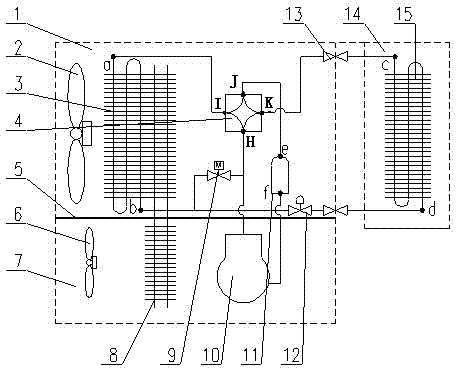

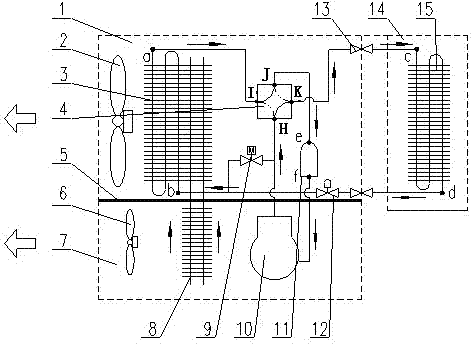

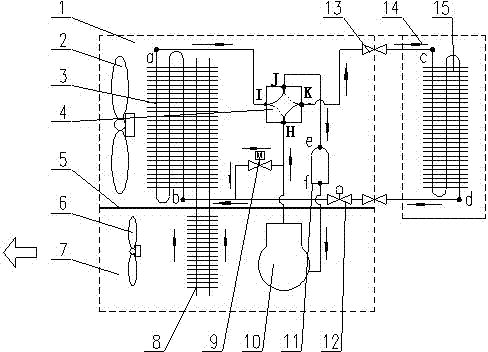

[0024] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following Example.

[0025] As shown in Fig. 1, the anti- and defrosting system of the heat pipe type air conditioner of the present invention is composed of three parts: a refrigerant circulation circuit, a compressor waste heat recovery channel, and a horizontal heat pipe. The refrigerant circulation circuit is the same as the conventional refrigeration system circulation circuit, including heat pump air conditioner outdoor unit 1, outdoor heat exchanger 3, compressor 10, outdoor heat exchanger fan 2, outdoor heat exchanger 3, and four-way reversing valve 4. Partition plate 5, compressor waste heat re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com