Lithium-sulfur secondary battery

A technology for lithium-sulfur secondary batteries and battery casings, which is applied to secondary batteries, battery pack components, circuits, etc., and can solve the difficulties of large-scale production of lithium-sulfur secondary batteries, shortened service life, and low Coulombic efficiency, etc. problems, to achieve the effects of easy mass production, prolonging service life, and suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

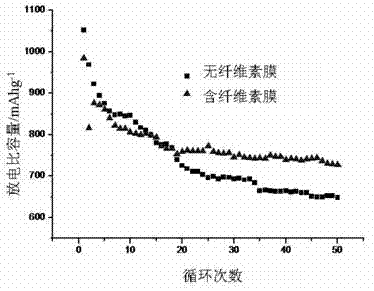

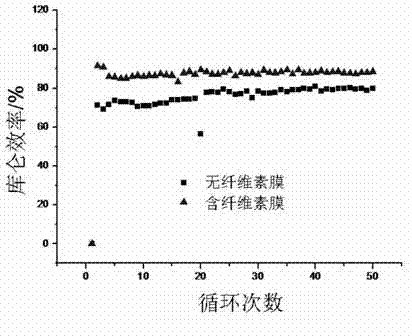

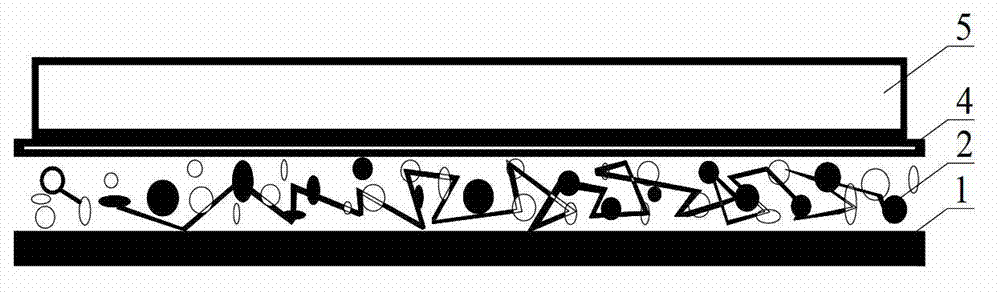

[0025] elemental sulfur S 8 , SP conductive agent, and PVDF binder are mixed evenly in NMP solvent at a mass ratio of 60:30:10 to form a slurry with a solid content of 30% as the positive electrode material, which is coated on the aluminum foil positive electrode current collector and dried in a vacuum oven. After drying in medium for 6 hours, it was pressed into a positive electrode sheet; the nitrocellulose membrane was placed between the positive surface of the positive electrode sheet and the Celgard2400 porous diaphragm, and a piece of lithium-silicon alloy as a negative electrode sheet was placed on the other side of the porous diaphragm, and pressed into a figure 2 The one shown in the figure is placed in the battery casing, and the solute is injected into the electrolyte solution of lithium hexafluorophosphate and ethylene methyl carbonate to make a CR2430 lithium-sulfur secondary button battery. After testing, the battery charge and discharge cut-off voltage is 1.5-2...

Embodiment 2

[0027] lithium polysulfide Li 2 S 4 , multi-walled carbon nanotube conductive agent, and water-based glue are uniformly mixed in water according to a mass ratio of 70:20:10 to form a slurry with a solid content of 35% as the positive electrode material. A lithium-sulfur secondary button battery with a cellulose film is tested after the battery is made. The charge-discharge cycle test is performed at a current density of 1C. The specific capacity of the first discharge is 805.0mAh / g, and the specific capacity after 50 cycles is 629.3 mAh / g.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap