Method for preparing BiOCl micro-flower nanometer photocatalysis material

A catalytic material and nano-light technology, applied in the field of nano-photocatalysis, can solve problems such as no preparation method is given, and achieve the effects of being conducive to large-scale engineering preparation, size increase, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment B

[0019] The preparation method of the BiOCl microflower nano-photocatalytic material in this embodiment is as follows:

[0020] Dissolve 0.8mmol of bismuth nitrate in 38ml of glycerol, and under stirring, add 2ml of the prepared potassium chloride (0.8mmol) aqueous solution dropwise into the bismuth nitrate solution, and the volume of glycerol in the resulting mixed solution The percentage is about 95%, and continue to stir for 10 minutes (minutes) and then sonicate for 30 minutes; transfer the above mixed solution to a high-pressure reactor (lined with a capacity of 50ml), and seal it. Put the reaction kettle into an oven and keep it warm at 110°C for 9 hours (hours). Take out the reaction kettle and let it cool naturally in the air. After cooling to room temperature, the product was taken out, the BiOCl photocatalyst was collected by centrifugation, and the sample was washed with deionized water and ethanol, and the obtained sample was dried in air at 60°C.

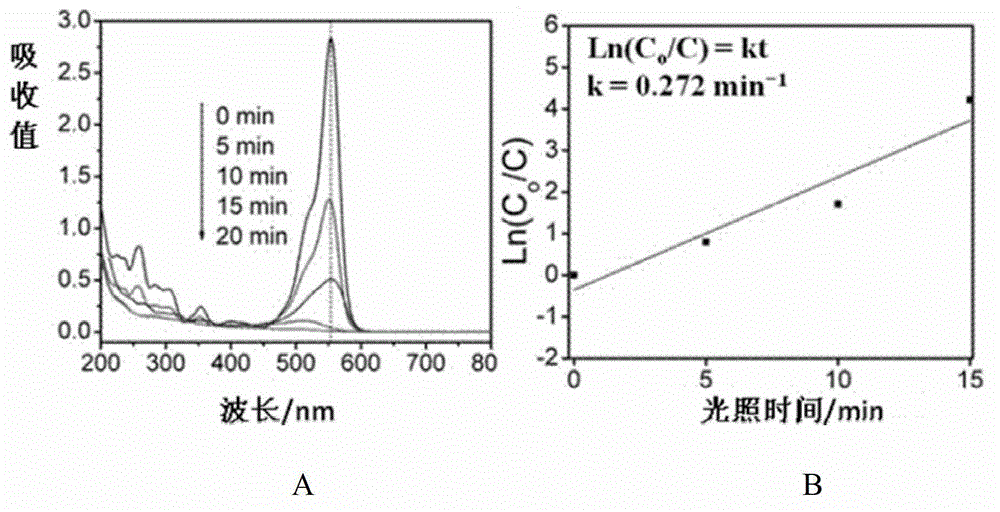

[0021] The sha...

Embodiment 2

[0024] Dissolve 0.8mmol of bismuth nitrate in 37ml of glycerol, and under stirring, add 3ml of the prepared potassium chloride (0.8mmol) aqueous solution dropwise into the bismuth nitrate solution, and the volume of glycerol in the resulting mixed solution The percentage is about 92.5%, and continue to stir for 30 minutes and then sonicate for 5 minutes; transfer the above mixed solution to a high-pressure reactor (liner capacity is 50ml), and seal it. Put the reaction kettle into an oven and keep it warm at 140°C for 6h. Take out the reaction kettle and let it cool naturally in the air. After cooling to room temperature, the product was taken out, the BiOCl photocatalyst was collected by centrifugation, and the sample was washed with deionized water and ethanol, and the obtained sample was dried at room temperature.

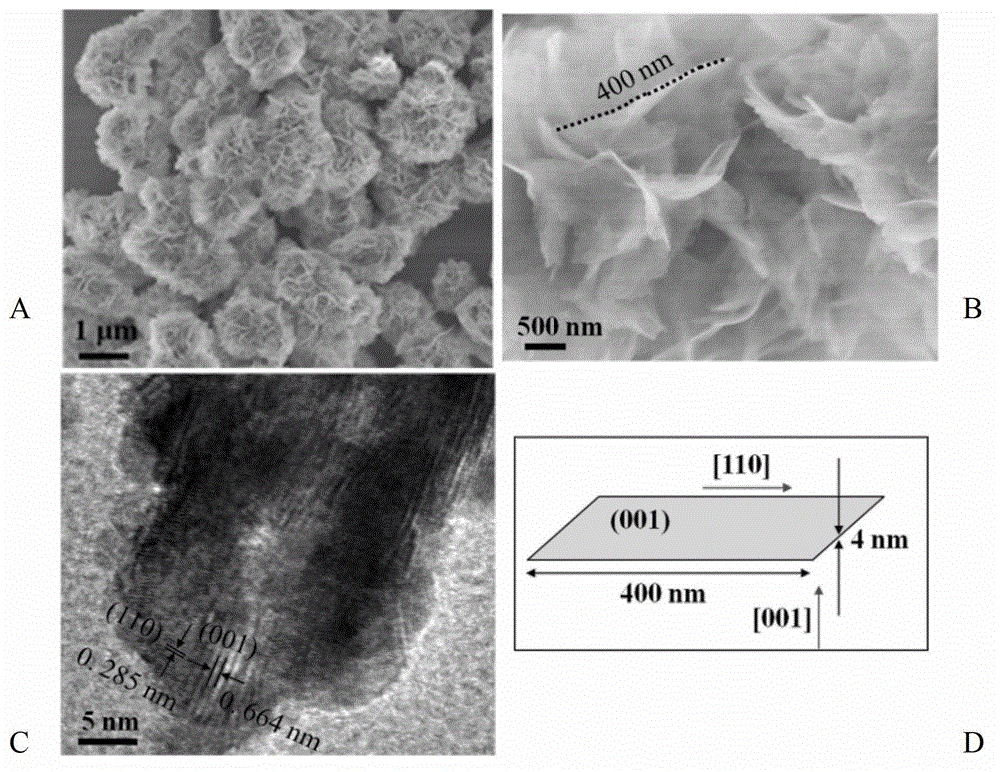

[0025] The microstructure of the above-obtained BiOCl microflower nano photocatalytic material is similar to that of Example 1. Through low-magnification scann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com