Polylactic acid resin combination

A technology of polylactic acid resin and composition, which is applied in the field of polylactic acid resin and its preparation, can solve the problems that the notched impact strength and elongation at break are not significantly improved, and achieve good anti-aging and anti-ultraviolet capabilities, simple equipment, and a process advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

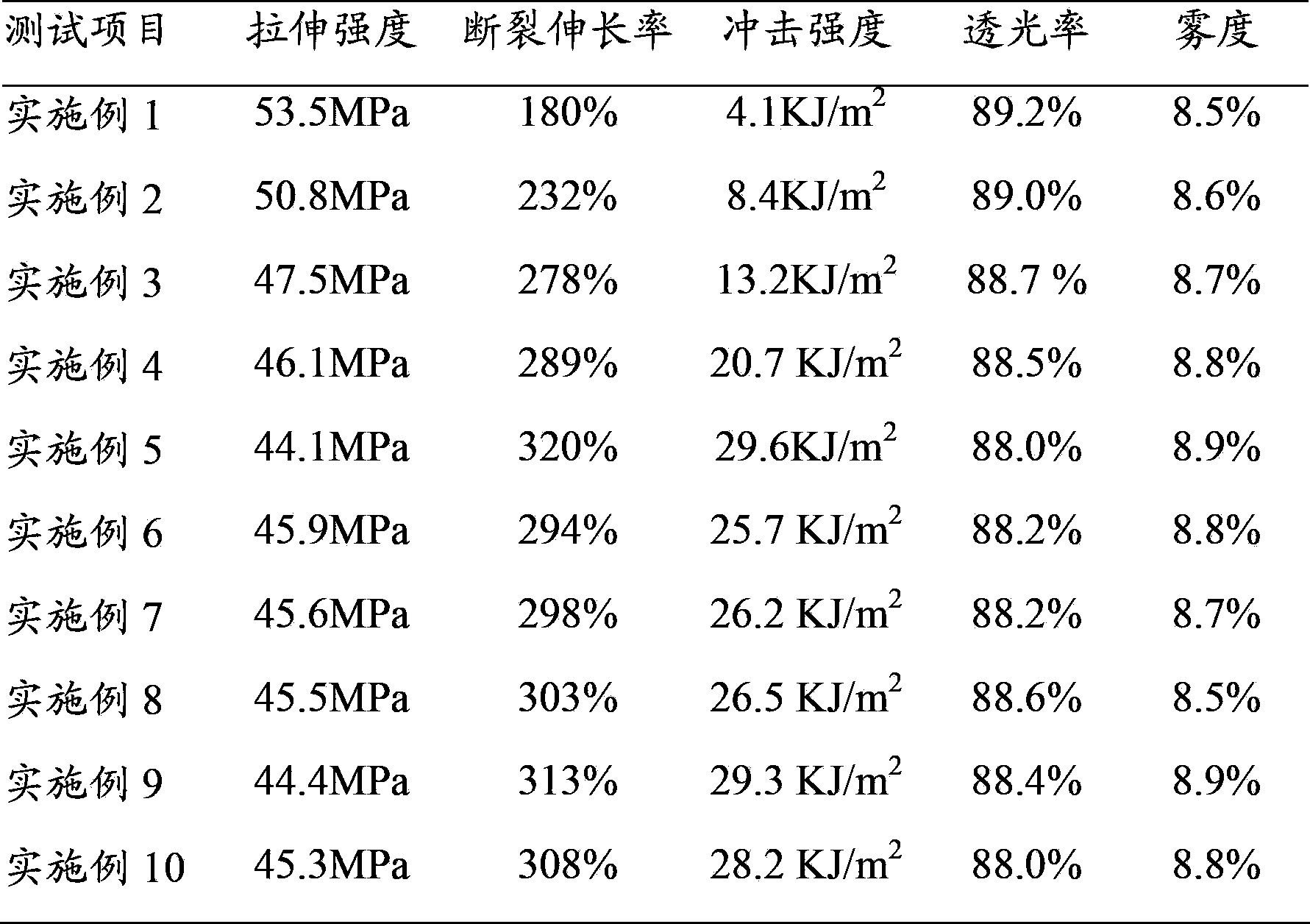

Examples

Embodiment 1

[0052] Add 77g of butyl acrylate, 20g of ethyl acrylate, 3g of glycidyl methacrylate, toluene and 0.1g of di-tert-butyl peroxide initiator mixture into the reactor, and heat the mixture to 130°C in an oil bath A polymerization reaction is carried out, and the reaction product is extruded by a twin-screw extruder to obtain a butyl acrylate-ethyl acrylate-glycidyl methacrylate terpolymer.

[0053] Mix 100g of polylactic acid with a number average molecular weight of 80,000 Daltons, 5g of the above-prepared butyl acrylate-ethyl acrylate-glycidyl methacrylate terpolymer and 0.5g of antioxidant with a mass ratio of 1:2. The mixture of agent 1010 and antioxidant 168 was first mechanically mixed into a premix, and then added to a rubber-plastic mixer for banburying. The process temperature was 185°C, the speed was 40 rpm, and the time was 5 minutes. The polylactic acid resin composition was prepared. .

[0054] The prepared polylactic acid resin was subjected to a mechanical perform...

Embodiment 2

[0056] Add 77g of butyl acrylate, 20g of ethyl acrylate, 3g of glycidyl methacrylate, toluene and 0.1g of di-tert-butyl peroxide initiator mixture into the reactor, and heat the mixture to 130°C in an oil bath A polymerization reaction is carried out, and the reaction product is extruded by a twin-screw extruder to obtain a butyl acrylate-ethyl acrylate-glycidyl methacrylate terpolymer.

[0057] Mix 100g of polylactic acid with a number average molecular weight of 80,000 Daltons, 10g of the above-prepared butyl acrylate-ethyl acrylate-glycidyl methacrylate terpolymer and 0.3g of antioxidant with a mass ratio of 1:2. The mixture of agent 1010 and antioxidant 168 was first mechanically mixed into a premix, and then added to a rubber-plastic mixer for banburying. The process temperature was 185°C, the speed was 40 rpm, and the time was 5 minutes. The polylactic acid resin composition was prepared. .

[0058] The prepared polylactic acid resin was subjected to a mechanical perfor...

Embodiment 3

[0060] Add 77g of butyl acrylate, 20g of ethyl acrylate, 3g of glycidyl methacrylate, toluene and 0.1g of di-tert-butyl peroxide initiator mixture into the reactor, and heat the mixture to 130°C in an oil bath A polymerization reaction is carried out, and the reaction product is extruded by a twin-screw extruder to obtain a butyl acrylate-ethyl acrylate-glycidyl methacrylate terpolymer.

[0061] Mix 100g of polylactic acid with a number average molecular weight of 200,000 Daltons, 15g of the above-prepared butyl acrylate-ethyl acrylate-glycidyl methacrylate terpolymer and 0.3g of antioxidant with a mass ratio of 1:2. The mixture of agent 1010 and antioxidant 168 was first mechanically mixed into a premix, and then added to a rubber-plastic mixer for banburying. The process temperature was 185°C, the speed was 40 rpm, and the time was 5 minutes. The polylactic acid resin composition was prepared. .

[0062] The prepared polylactic acid resin was subjected to a mechanical perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com