Epoxy anticorrosion decoration paint

An anti-corrosion coating, rust and anti-corrosion technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., to achieve the effect of strong tolerance, good film formation, and superior substrate adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

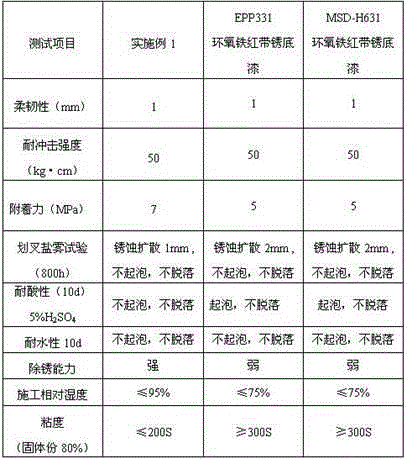

Examples

Embodiment 1~ Embodiment 4

[0045] The preparation technology of epoxy band rust anticorrosion coating in embodiment 1~embodiment 4 is as follows:

[0046] Weigh the ingredients contained in component A as shown in Table 1, first put epoxy resin E51, ethylene glycol butyl ether, zirconate coupling agent, and silane coupling agent into the mixer in sequence, and mix at 800~1000 rpm Stir for 10 min, and add zinc phosphate, sericite powder, aluminum tripolyphosphate, and red iron oxide in sequence under stirring, and continue stirring for 10 min to obtain component A.

[0047] Weigh the components contained in component B as shown in Table 1, first put the amino-terminated epoxy-amine adduct and n-butanol into the mixer in sequence, stir at 800~1000 rpm for 10 min, and in the stirring state Add tannic acid, phytic acid, and ethanol in turn, and continue stirring for 10 min to obtain component B.

[0048] When in use, mix component A and component B according to the weight ratio of 4:1, and stir evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com