Strontium, titanium and boron composite microalloying manganese brass and preparation method of manganese brass

A technology of microalloying and manganese brass, applied in the field of manganese brass and its preparation, achieves the effects of fine grain size, breaking technical blockade and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

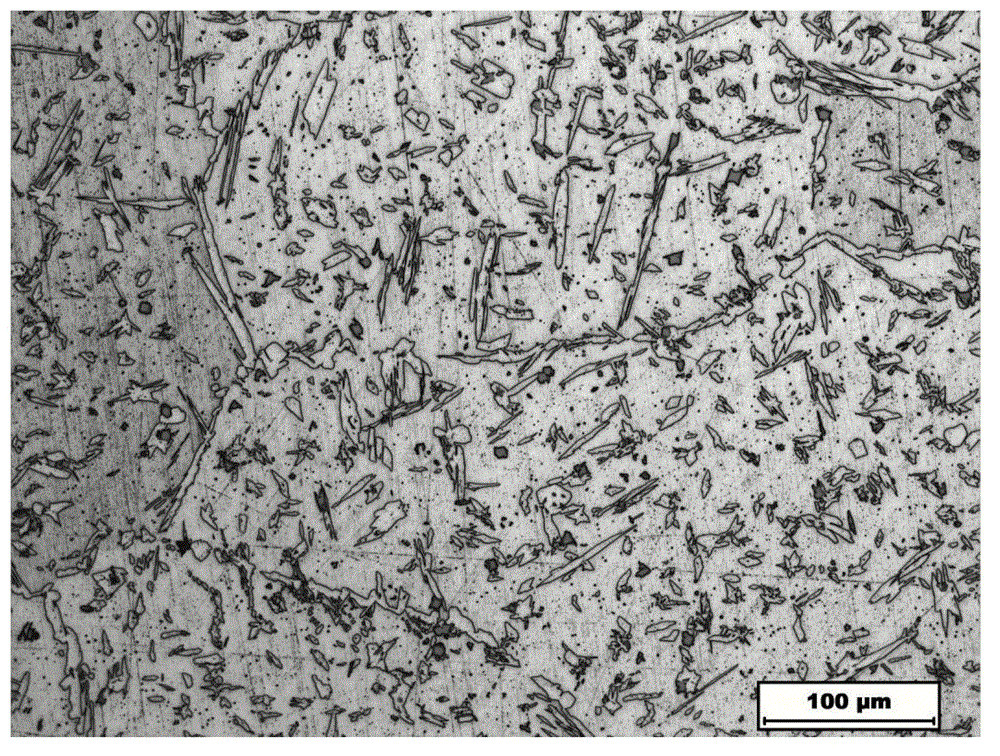

[0028] like figure 1 shown.

[0029] A strontium, titanium and boron composite microalloyed manganese brass, its preparation method:

[0030] Take 8.3624kg as an example.

[0031] First, 8.3 kg of commercially available manganese brass (52-62% of copper, 0.5-4.0% of manganese, 0.5-3.0% of aluminum, 35-40% of zinc, 0.5-2.5% of iron, 1% of nickel, and the balance of A small amount of impurity elements, the same below) After melting, add 21g of Al-Sr master alloy (89.85%Al, 9.89%Sr (can fluctuate between 8.901% and 10.879), 0.16%Fe, 0.10%Si) (loss rate of Sr about 40%), 41.4g AlTiB master alloy (93.69%Al, 5.01%Ti (can fluctuate between 4.509%~5.511%, loss rate is about 8%), 0.98%B (can be between 0.882%~1.078%) Float between), 0.19%Fe, 0.13%Si), the above-mentioned master alloy can be purchased directly from the market, or can be prepared by yourself by conventional methods. During the melting process, the former master alloy is melted and then the latter master alloy is added...

Embodiment 2

[0035] A strontium, titanium and boron composite microalloyed manganese brass, its preparation method:

[0036] Take 8.3624kg as an example.

[0037] First, after melting 8.305kg of commercially available manganese brass (composition: 58.51Cu, 38.47Zn, 1.16Mn, 0.81Al, 0.72Fe, 0.23Ni, the numbers before all element symbols in the examples represent mass percentages, the same below) Add 16g of Al-Sr master alloy (89.85%Al, 9.89%Sr, 0.16%Fe, 0.10%Si) (the loss rate of Sr is about 40%), 41.4g of AlTiB master alloy (93.69%Al, 5.01%Ti, 0.98 %B, 0.19%Fe, 0.13%Si) (the loss rate of Ti is about 8%), the master alloy can be purchased directly from the market, or can be prepared by conventional methods. After melting, add the latter intermediate alloy; after it is completely melted, pour it into a ladle, let it stand for 1-5 minutes, remove the slag and cast it into an ingot; that is, the manganese brass with composite microalloying of strontium, titanium and boron is obtained .

[00...

Embodiment 3

[0041] A strontium, titanium and boron composite microalloyed manganese brass, its preparation method:

[0042] Take 8.3624kg as an example.

[0043] First, 8.304 kg of commercially available manganese brass (52-62% of copper, 0.5-4.0% of manganese, 0.5-3.0% of aluminum, 35-40% of zinc, 0.5-2.5% of iron, 1% of nickel, and the balance of A small amount of impurity elements, the same below) After melting, add 42g Al-Sr master alloy (89.85%Al, 9.89%Sr, 0.16%Fe, 0.10%Si) (the loss rate of Sr is about 40%), 19gAlTiB master alloy (93.69% %Al, 5.01%Ti, 0.98%B, 0.19%Fe, 0.13%Si) (the loss rate of Ti is about 8%), described master alloy can be purchased directly from the market, also can adopt conventional method to prepare by oneself, During the melting process, wait for the former master alloy to melt before adding the latter master alloy; after it is completely melted, pour it into a ladle, let it stand for 1 to 5 minutes, remove the slag and cast it into an ingot; that is, stronti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com