Method for improving crystallinity of metal film and metal film material prepared by method

A metal thin film, crystallization technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of affecting the penetration rate, excessive thickness, affecting the conductivity of the test piece T2, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

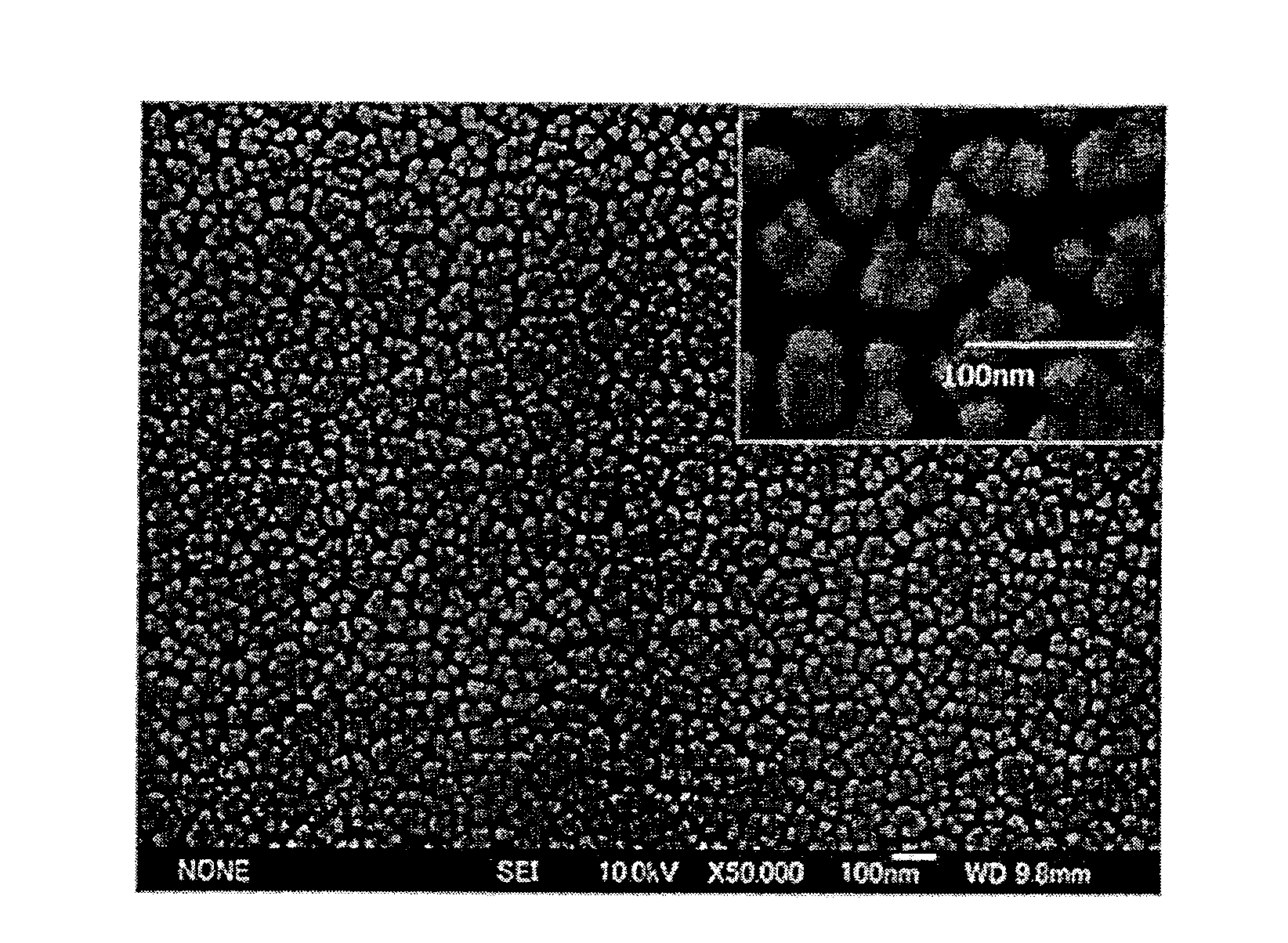

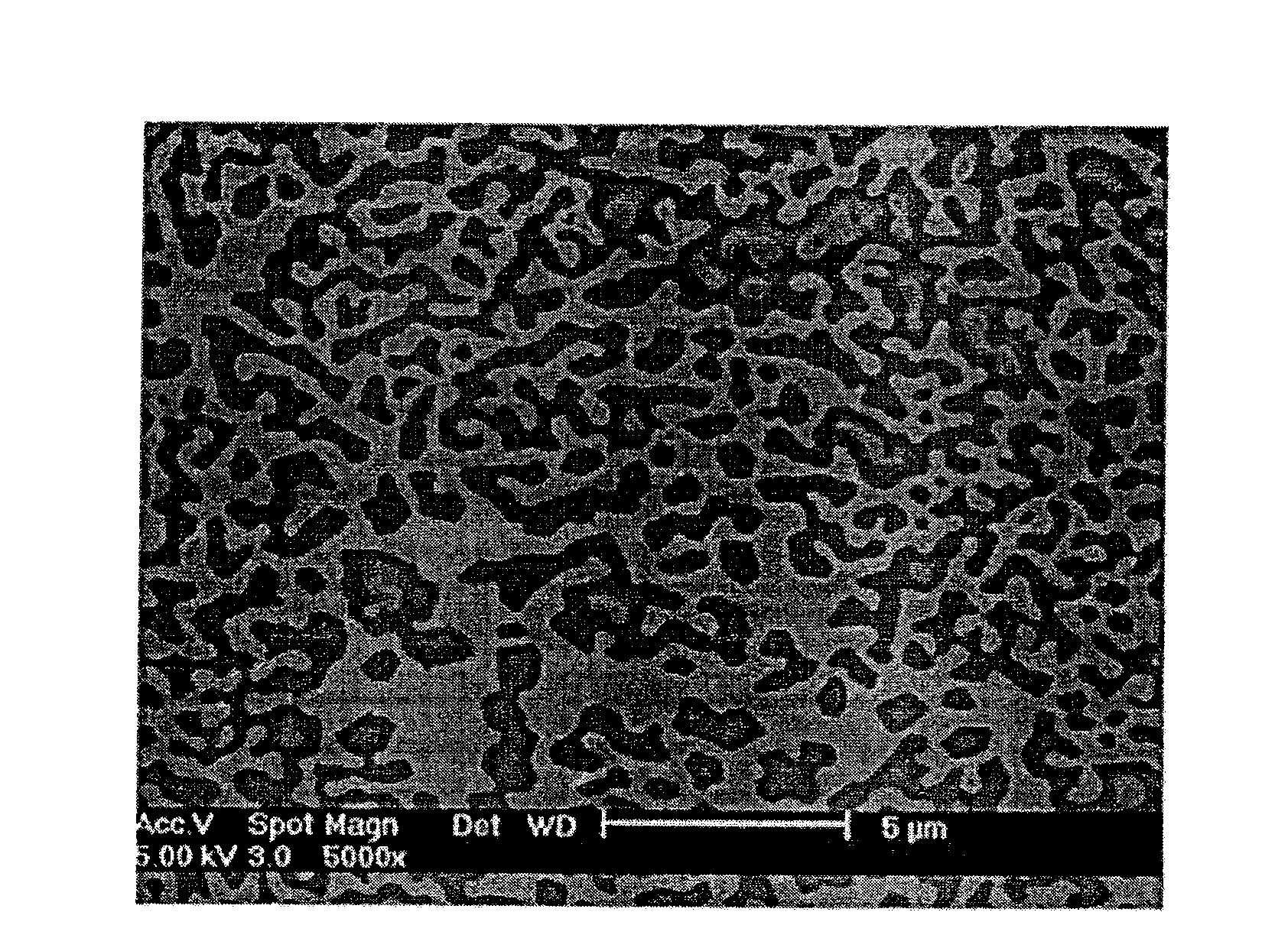

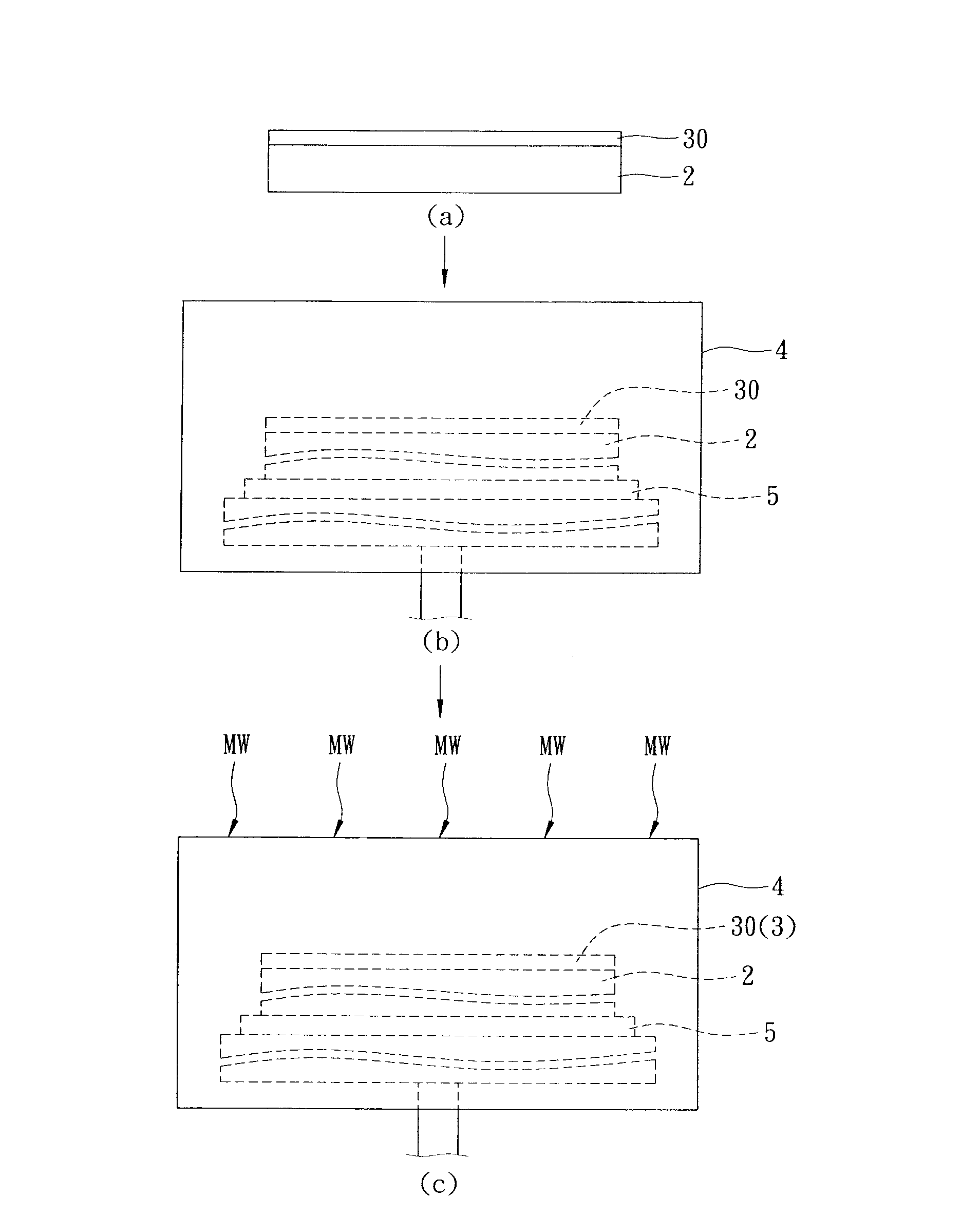

specific example 1

[0065] A specific example 1 (E1) of the method of utilizing microwaves to improve the crystallinity of metal thin films in the present invention is substantially the same as the comparative example 1 (CE1), and its difference is that a Cu thin film of the specific example 1 (E1) is It was further placed on a silicon substrate in a vacuum chamber with a working pressure of 0.25 Torr, and the Cu thin film was subjected to microwave crystallization treatment for 60 seconds with an output power of 1100 W to obtain a crystallized Cu thin film. In the specific example 1 (E1) of the present invention, the thickness and area of the silicon substrate are 375±25m and 2cm×2cm, respectively.

specific example 2

[0069] A specific example 2 (E2) of the method of utilizing microwaves in the present invention to improve the crystallinity of metal thin films is substantially the same as the specific example 1 (E1), and its difference is that the metal thin film of the specific example 2 (E2) is a A Pd thin film with a thickness of about 15 nm, and the microwave crystallization treatment was carried out for 180 seconds.

specific example 3

[0075] A specific example 3 (E3) of the method of utilizing microwaves to improve the crystallinity of a metal thin film in the present invention is substantially the same as the specific example 1 (E1), and its difference is that the metal thin film of the specific example 3 (E3) is a Au thin film with a thickness of about 10 nm, and the microwave crystallization treatment is carried out for 30 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com