Potato circulating production process by means of detoxified potato test tube

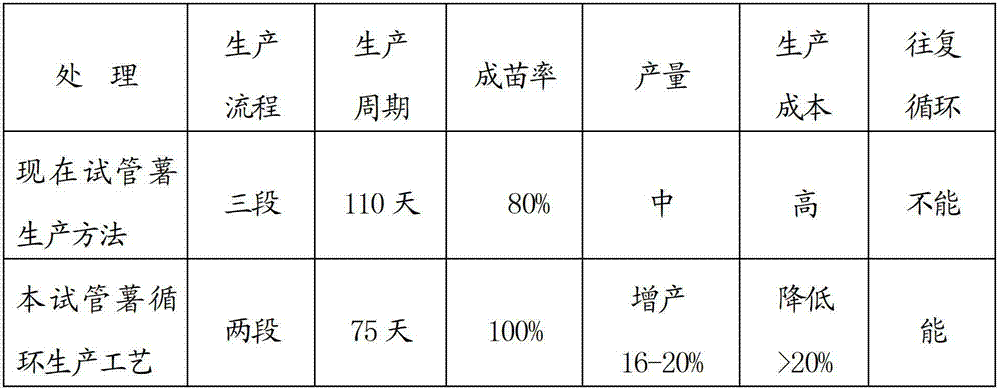

A production process and test-tube tuber technology, applied in the field of virus-free potato test-tube tuber production, can solve the problems of long production cycle, many production processes, increased waste of resources and environmental pollution, etc., achieve uniform growth, simple production process, shorten The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

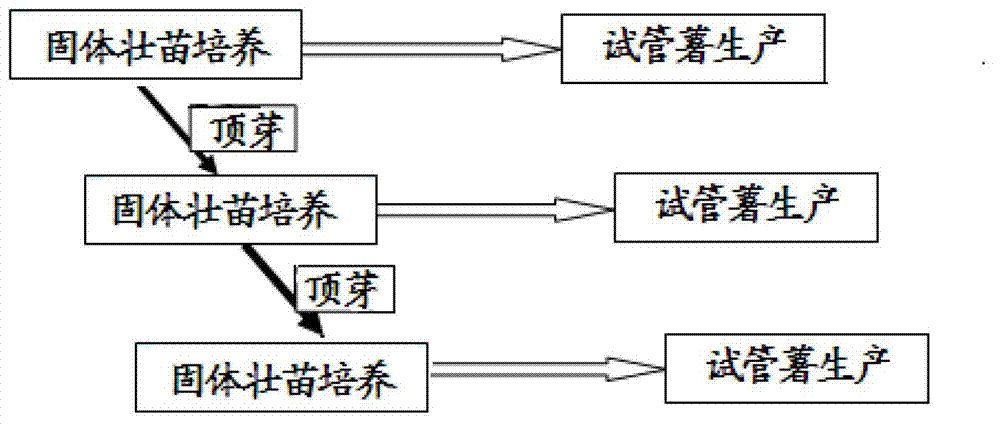

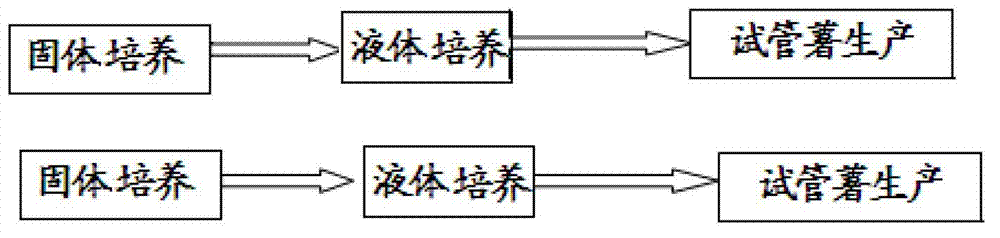

Method used

Image

Examples

Embodiment 1

[0026] Take test-tube seedlings with 4 to 5 stem nodes, cut into single stem nodes under sterile conditions, and inoculate on the strong seedling medium, the light time is 16h·d -1 , Light intensity 2500 ~ 3000lx. After 3 to 4 weeks, enough test-tube seedlings with the same source were induced, and the test-tube seedlings were subjected to the following 5 treatment methods using the induction medium formula and inoculation method (see Table 1), first cultivated in light for 5 days, and then transferred to Cultivate induced tube tubers in a dark room at 15-20°C. 10 bottles were treated each time, with 20 plants per bottle, repeated 3 times. After 35 days of treatment, the number of tuber tubers was investigated, and after 55 days, the total number of tubers, the number of large tubers and the grain weight were investigated. (Standard: large potato d>5mm; knot potato d>3mm). The test results are shown in Table II.

[0027] Table 1. Processing method

[0028]

[0029] (In...

Embodiment 2

[0036] The applicant selects the test-tube seedlings of the potato variety Qinyu No. 30 that has passed the virus-free detection. According to the design method of the application, the test-tube seedlings are subtracted from the top buds, and the test-tube tuber induction medium is added to induce tuber formation. The clipped top buds are used As a basic seedling breeding, a total of 820 bottles of induced test tube tubers were produced, harvested after 2 and a half months, a total of 20090 tubers, with a total weight of 2034 grams, an average of 24.5 tubers and 2480.5 mg per bottle.

Embodiment 3

[0038] Utilize the test-tube plantlets propagated by terminal buds in Example 2, cut off the terminal buds and add an induction medium to induce tuber formation, and the clipped terminal buds are used as basic seedlings for breeding, and a total of 2000 bottles of induced test-tube tubers are produced. The temperature was controlled at 15-18°C for the first 20 days of tuber induction, and 20-22°C for the later period. After 2 months, a total of 56,780 tubers were harvested, with a total weight of 6,485 grams, and an average of 28.3 tubers and 3,242.5 mg per bottle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com