Preparation method of molybdenum trioxide nanorod

A technology of molybdenum trioxide and nanorods, which is applied in the field of nanomaterials to achieve high-efficiency growth, simple preparation process, and low defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

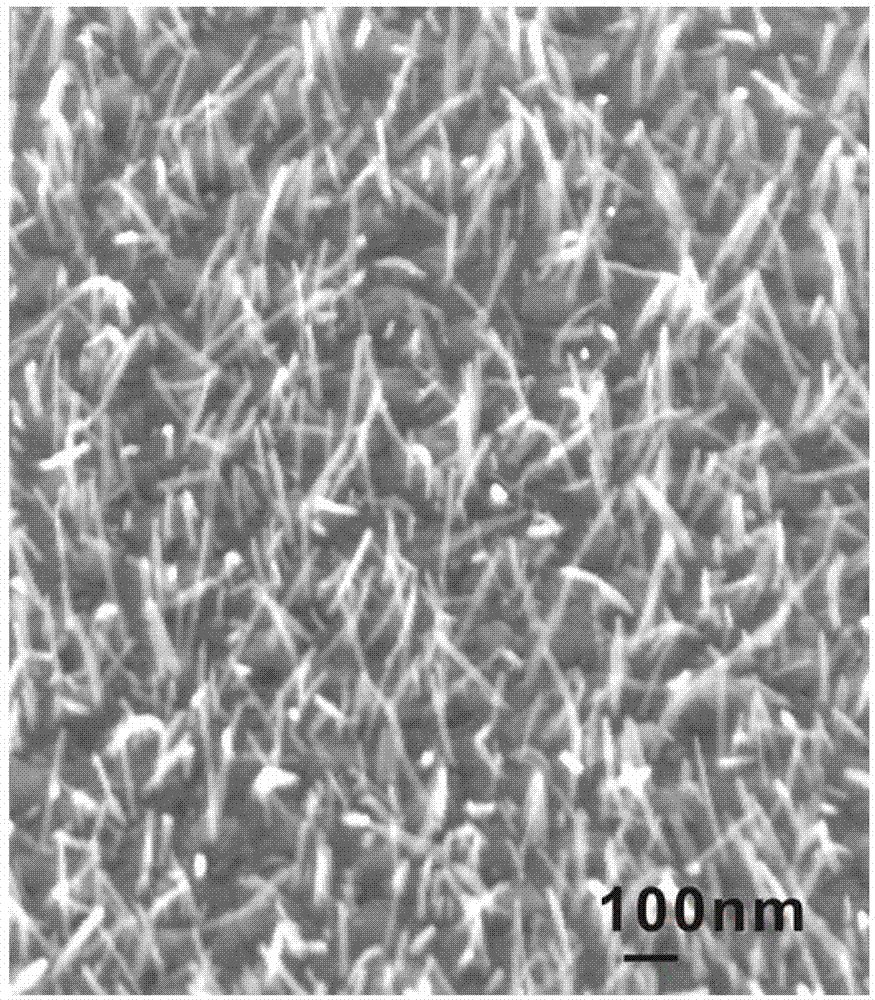

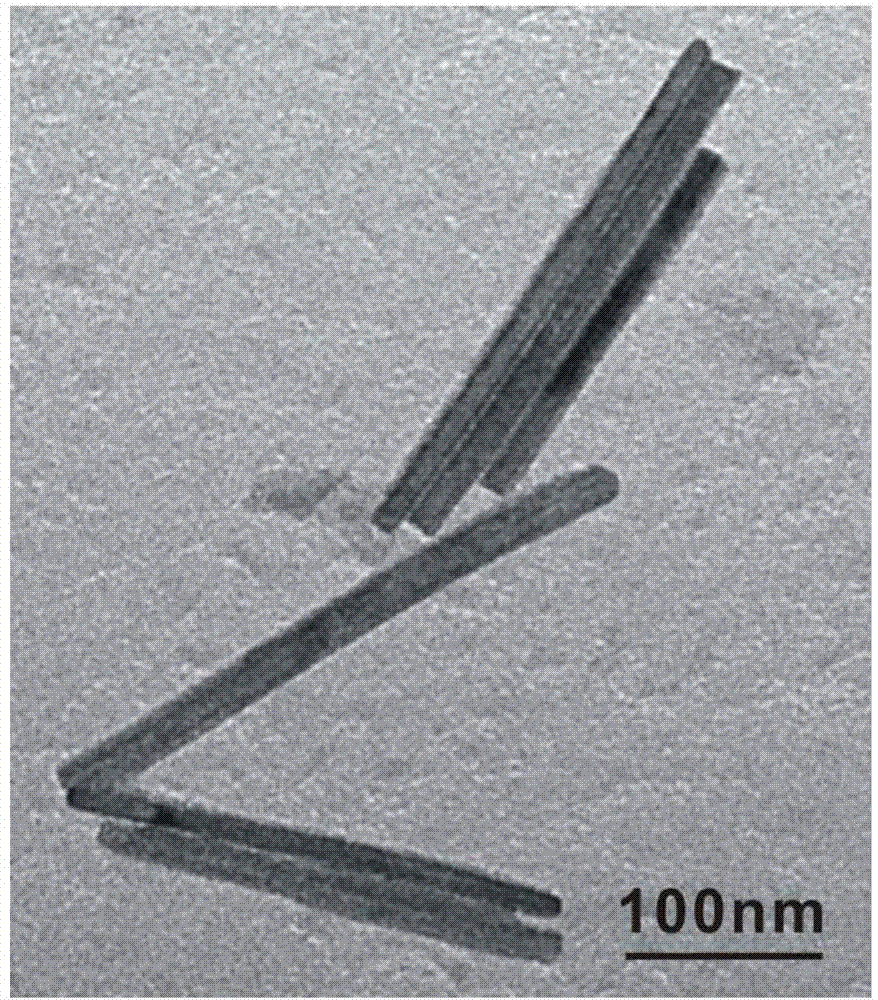

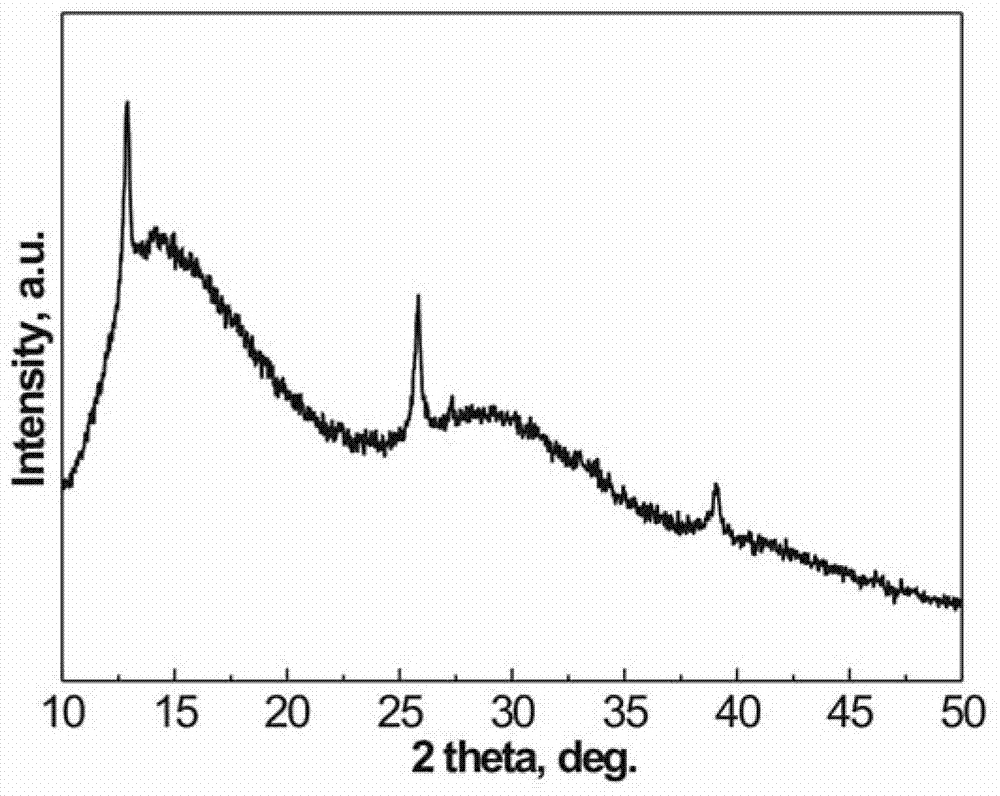

[0034] Deposition of orthorhombic MoO on single crystal Si(100) using an ArF excimer pulsed laser system with a wavelength of 193 nm 3 Nanorod array, the specific operation steps are:

[0035] Step 1, performing surface cleaning treatment on the single crystal silicon Si (100) substrate. The specific operation is as follows: first, immerse the single crystal silicon Si (100) substrate in acetone and ethanol solution for ultrasonic cleaning, then put it into deionized water for ultrasonic cleaning, and then dry it with cold air.

[0036] Step 2. Fix the substrate with a clean surface on the substrate holder in the vacuum growth chamber, and install α-MoO with a diameter of 60mm 3 For the target, the distance between the target and the substrate is 70mm, and the front of the substrate is kept facing the target.

[0037] Step 3. After the target material and the substrate are installed, close the vacuum growth chamber, use the combined vacuum acquisition system of the mechanica...

Embodiment 2

[0044] Deposition of orthorhombic MoO on single crystal Si(100) using an ArF excimer pulsed laser system with a wavelength of 193 nm 3 Nanorod array, the specific operation steps are:

[0045] Step 1, performing surface cleaning treatment on the single crystal silicon Si (100) substrate. The specific operation is as follows: first, immerse the single crystal silicon Si (100) substrate in acetone and ethanol solution for ultrasonic cleaning, then put it into deionized water for ultrasonic cleaning, and then dry it with cold air.

[0046] Step 2. Fix the substrate with a clean surface on the substrate holder in the vacuum growth chamber, and install α-MoO with a diameter of 60mm 3 For the target, the distance between the target and the substrate is 40 mm, and the front of the substrate is kept facing the target.

[0047] Step 3. After the target material and the substrate are installed, close the vacuum growth chamber, use a mechanical pump and a molecular pump to vacuum the g...

Embodiment 3

[0054] Deposition of orthorhombic MoO on single crystal Si(100) using an ArF excimer pulsed laser system with a wavelength of 193 nm 3 Nanorod array, the specific operation steps are:

[0055] Step 1, performing surface cleaning treatment on the single crystal silicon Si (100) substrate. The specific operation is as follows: first, immerse the single crystal silicon Si (100) substrate in acetone and ethanol solution for ultrasonic cleaning, then put it into deionized water for ultrasonic cleaning, and then dry it with cold air.

[0056] Step 2. Fix the substrate with a clean surface on the substrate holder in the vacuum growth chamber, and install α-MoO with a diameter of 60mm 3 The target, the distance between the target and the substrate is 80mm, and the front of the substrate is kept facing the target.

[0057] Step 3. After the target material and the substrate are installed, close the vacuum growth chamber, use the combined vacuum acquisition system of the mechanical pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com