Feed additive for fattening sheep

A technology for feed additives and fattening sheep, applied in animal feed, animal feed, applications, etc., can solve problems such as difficulty in popularization and application, poor effect, adverse reactions, etc., achieve high biological utilization, fast absorption by the body, and increase appetite Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

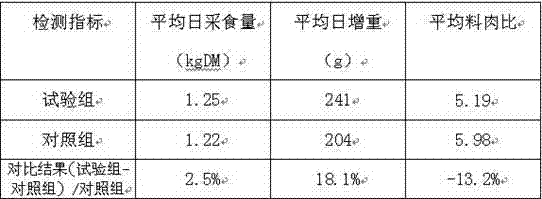

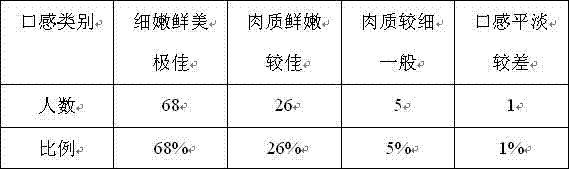

Examples

preparation example Construction

[0021] The preparation steps of the feed additive for fattening sheep are as follows:

[0022] Step 1. Take the hawthorn, eucommia leaves, Gynostemma pentaphyllum and mulberry leaves from the raw materials, then separate the hawthorn core and meat, put the hawthorn meat in a constant temperature drying oven and dry at 30-60°C for 10-16 hours, and place the hawthorn core Stir-fry in a frying pan until it is scorched black, set aside; shred Eucommia leaves and place in a frying pan, spray with 6% salt water with a mass percentage concentration of 50% of the mass of Eucommia leaves, then stir-fry for 30-60 minutes, Standby; Gynostemma pentaphyllum is placed in a constant temperature drying box and dried at 40-80°C for 6-12h, and set aside; mulberry leaves are dried at 30-50°C for 4-8h, set aside; and then each of the above-mentioned treated Raw materials are pulverized and passed through an 80-mesh sieve to obtain coarse powder, which is set aside;

[0023] Step 2. Use an adjust...

Embodiment 1

[0028] A feed additive for fattening sheep, in which the mass percentage of hawthorn powder is 30%, the mass percentage of Eucommia leaf powder is 30%, the mass percentage of Gynostemma pentaphyllum powder is 20%, and the mass percentage of mulberry leaf powder is 20%, The quality of adding nano zinc oxide is 1.25% of the total amount of hawthorn powder, eucommia leaf powder, Jiaogulan powder and mulberry leaf powder.

[0029] The preparation steps of the feed additive for fattening sheep are as follows:

[0030]Step 1. Take hawthorn, eucommia leaves, Gynostemma pentaphylla and mulberry leaves from the raw materials, then separate the hawthorn core and meat, put the hawthorn meat in a constant temperature drying oven and dry at 30°C for 16 hours, and put the hawthorn core in a frying pan Stir-fry until charred, set aside; shred Eucommia leaves, put them in a frying pan, spray with 6% salt water, the mass of salt water is 50% of the mass of Eucommia leaves, then stir-fry for 30...

Embodiment 2

[0035] A feed additive for fattening sheep, in which the mass percentage of hawthorn powder is 32%, the mass percentage of Eucommia leaf powder is 28%, the mass percentage of Gynostemma pentaphyllum powder is 18%, and the mass percentage of mulberry leaf powder is 18%, The quality of the added nano-zinc oxide is 1.5% of the total amount of hawthorn powder, eucommia leaf powder, Jiaogulan powder and mulberry leaf powder.

[0036] The preparation steps of the feed additive for fattening sheep are as follows:

[0037] Step 1. Take hawthorn, eucommia leaves, Gynostemma pentaphyllum and mulberry leaves from the raw materials, then separate the hawthorn core and meat, put the hawthorn meat in a constant temperature drying oven and dry at 45°C for 13 hours, and put the hawthorn core in a frying pan Stir-fry until charred, set aside; shred Eucommia leaves, put them in a frying pan, spray with 6% salt water, the mass of salt water is 50% of the mass of Eucommia leaves, then stir-fry fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com