Pressurization density method production technique and device for controlling sulfonation rate in sulfonation production of anionic surfactant

A surfactant and production process technology, applied in the direction of feeding devices, sulfonate preparation, chemical instruments and methods, etc., can solve the problems of high control cost, control error, and many control variables, and achieve low cost and convenient operation , The effect of changing the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

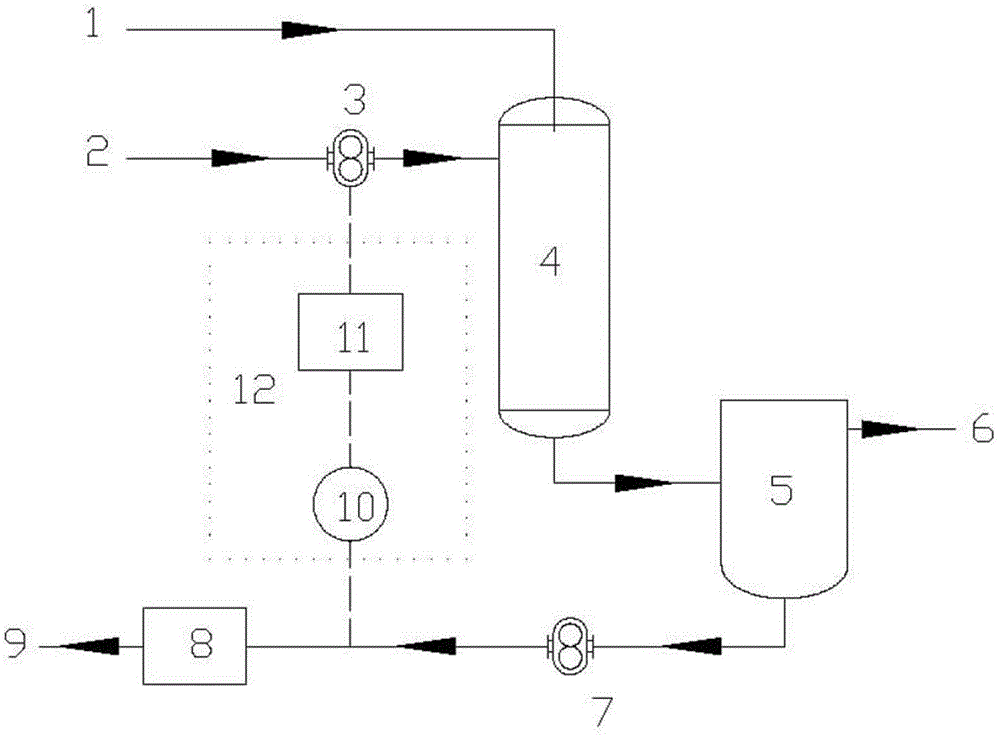

[0031] AEO 2 Enter the membrane tube sulfonator through the organic material pump, SO 3 The gas enters from the top of the membrane sulfonator. The separated tail gas goes to the tail gas absorption system; after the ester comes out of the gas-liquid separator, it is transported to the neutralization system by the ester pump, the outlet pressure of the ester pump is kept at 0.6MPa through the back pressure valve, and the outlet density of the ester pump is Control between 1.0220~1.0230g / ml. After the whole system is stabilized, the ester neutralization value is stable at 111.0~112.0mgNaOH / g.

[0032] Under this process, the AES product index that obtains is active matter 70.1%, sulfate 0.6%, unsulfurized matter 1.0%, color and luster 15Hazen (10% ethanol aqueous solution of 5% active matter; promptly comprise the active matter of 5% volume content in the product , 10% ethanol aqueous solution by volume; the same below).

Embodiment 2

[0034] α-olefin enters the membrane tube sulfonator through the organic material pump, and SO3 gas enters from the top of the membrane sulfonator. The separated tail gas goes to the tail gas absorption system; after the ester comes out of the gas-liquid separator, it is transported to the neutralization system by the ester pump, the outlet pressure of the ester pump is kept at 0.5MPa through the back pressure valve, and the outlet density of the ester pump is Control between 0.9770~0.9780g / ml. After the whole system is stabilized, the ester neutralization value is stable at 130.0~131.0mgNaOH / g.

[0035] Under this process, the product obtained has 35% active matter, 1.3% sulfate, 1.2% petroleum ether extract, and 35 Hazen color (10% ethanol aqueous solution of 5% active matter).

Embodiment 3

[0037] The methyl ester enters the membrane tube sulfonator through the organic material pump, and the SO 3 The gas enters from the top of the membrane sulfonator. The separated tail gas goes to the tail gas absorption system; after the ester comes out of the gas-liquid separator, it is transported to the neutralization system by the ester pump, the outlet pressure of the ester pump is kept at 0.6MPa through the back pressure valve, and the outlet density of the ester pump is Control between 1.0230~1.0240g / ml. After the whole system is stabilized, the ester neutralization value is stable at 175~176mgNaOH / g.

[0038] Under this process, the product obtained has 85.0% active matter, 1.0% sulfate, 1.2% petroleum ether extract, and a color of 20 Hazen (10% ethanol aqueous solution of 5% active matter).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com