Rapid preparing method for solar cell CIGS target material

A solar cell and target material technology, which is applied in the field of photoelectric materials and solar cells, can solve the problems of complex preparation methods and long duration, and achieve the effects of simple and effective preparation methods, increased relative density of blocks, and improved preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

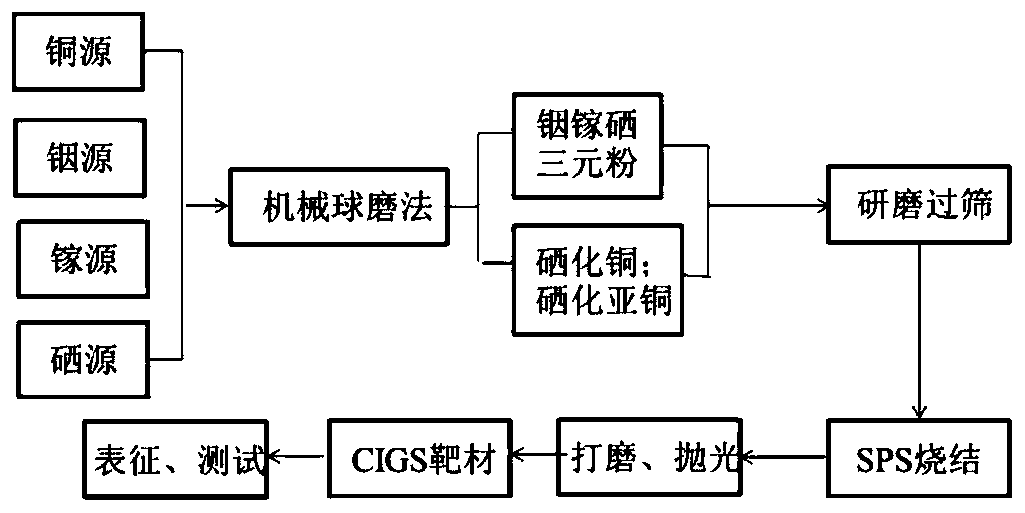

[0032] A kind of rapid preparation method of solar cell CIGS target material, it comprises the following steps:

[0033] (1) According to the atomic ratio of indium powder, gallium grains and selenium powder at 3:1:6, weigh 7.916g of indium powder, 1.602g of gallium grains and 10.887g of selenium powder; copper powder and selenium powder at an atomic ratio of 2:1, Weigh 12.338g of copper powder and 7.664g of selenium powder; the atomic ratio of copper powder and selenium powder is 1:1, and weigh 8.918g of copper powder and 11.082g of selenium powder.

[0034] (2) Put the above-mentioned three types of raw materials that have been weighed into the agate-lined ball mill tank respectively, take out after 24 hours of high-speed ball milling at 480 rpm, and obtain samples after centrifugal drying, and then mix the three types of raw material powders through ball milling Afterwards, take out and dry, and take out the product;

[0035] (3) Weigh 5g of the product into a graphite mol...

Embodiment 2

[0041] A kind of rapid preparation method of solar cell CIGS target material, it comprises the following steps:

[0042] (1) According to the atomic ratio of indium powder, gallium grains and selenium powder at 4:1:7, weigh 10.041g of indium powder, 1.512g of gallium grains and 12.072g of selenium powder; copper powder and selenium powder at an atomic ratio of 3:2, Weigh 10.961g of copper powder and 9.064g of selenium powder; the atomic ratio of copper powder and selenium powder is 1:1, and weigh 8.918g of copper powder and 11.082g of selenium powder.

[0043] (2) Put the weighed above-mentioned raw materials into a ball mill jar lined with agate, take out after high-speed ball milling for 36 hours at 430 rpm, obtain a sample after centrifugal drying, take out and dry after ball mill mixing, and take out the product;

[0044] (3) Weigh 10g of the product and put it into a graphite mold, put it into the SPS sintering furnace cavity, set the process parameters, raise the tempera...

Embodiment 3

[0047] A kind of rapid preparation method of solar cell CIGS target material, it comprises the following steps:

[0048] (1) According to the atomic ratio of indium powder, gallium grains and selenium powder at 3:2:10, weigh 4.322g of indium powder, 1.746g of gallium grains and 9.931g of selenium powder; copper powder and selenium powder at an atomic ratio of 6:5, Weigh 9.824g of copper powder and 10.184g of selenium powder; the atomic ratio of copper powder and selenium powder is 1:1, and weigh 8.918g of copper powder and 11.082g of selenium powder.

[0049] (2) put the weighed above-mentioned raw materials into the ball mill jar of agate lining, take out after high-speed ball milling at 480 rpm for 20h, obtain the sample after centrifugal drying, take out and dry after ball mill mixing, and take out the product;

[0050] (3) Weigh 10g of the product and place it in a graphite mold, put it into the SPS sintering furnace cavity, set the process parameters, raise the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com