Manganese oxide adsorbent and preparation method thereof

A technology of manganese oxide and adsorbent, which is applied in the direction of chemical instruments and methods, other chemical processes, process efficiency improvement, etc., can solve the problems such as the complexity of Li+ separation technology, and achieve easy preparation methods, mild reaction conditions, and extensive industrial application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

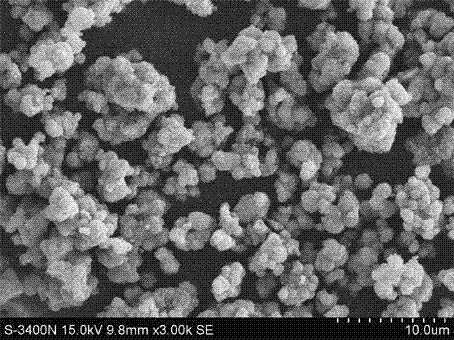

[0022] Mix the manganese-containing compound and the lithium-containing compound with a weight ratio of 1:1, and then heat it to 200°C in a closed container in the air, keep the temperature for 24 hours, and take pictures with a Hitachi-S3400N scanning electron microscope. Such as figure 1 shown.

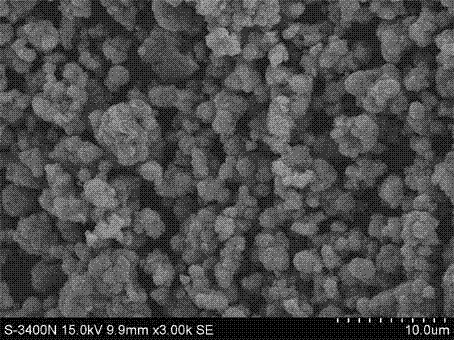

[0023] The resulting mixture was dried at 60°C, and then kept at 500°C for 6 hours to obtain a powder containing manganese oxide, which was photographed with a Hitachi-S3400N scanning electron microscope. The electron microscope photos are as follows: figure 2 shown.

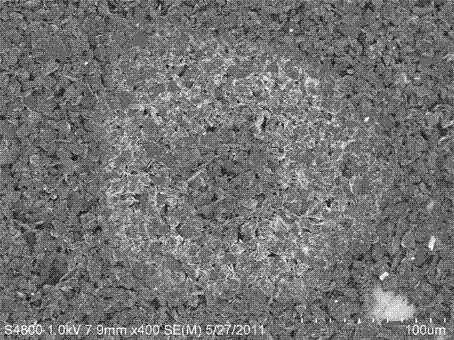

[0024] Take 140 parts by weight of the obtained powdered manganese oxide and 25 parts of binder, mix evenly, and finally form by extrusion, and drop the molding into the solution of ethanol and deionized water to prepare the manganese oxide adsorbent . Adopt Hitachi-S4800 scanning electron microscope to take pictures of manganese oxide adsorbent, the electron microscope photos are as follows image 3 shown.

[0...

Embodiment 2

[0027] Mix the manganese-containing compound and the lithium-containing compound with a weight ratio of 1:1.5 evenly, then heat to 100°C in a closed container in the air, and keep the temperature for 48 hours.

[0028] The resulting mixture was dried at 80°C, and then kept at 600°C for 5 hours to obtain a powder containing manganese oxide.

[0029] Take 120 parts by weight of the obtained powdered manganese oxide and 28 parts of binder, mix evenly, and finally form by centrifugation, and drop the molded product into the ethanol solution to prepare the manganese oxide adsorbent.

[0030] The manganese oxide adsorbent is used for brine adsorption, and the brine passes through the manganese oxide adsorbent until it is saturated, and the concentration of lithium ions in the brine before and after adsorption is tested by an atomic absorption spectrophotometer. The test shows that the adsorption concentration of the adsorbent can reach the original brine The medium concentration is ...

Embodiment 3

[0032] Mix the manganese-containing compound and the lithium-containing compound with a weight ratio of 1:3, and then heat to 150°C in a closed container in the air, and keep the temperature for 36 hours.

[0033] The resulting mixture was dried at 100°C, and then kept at 400°C for 8 hours to obtain a powder containing manganese oxide.

[0034] Take 100 parts by weight of the obtained powdery manganese oxide and mix evenly with 30 parts of binder, and finally form by centrifugation, and drop the molded product into the ethanol solution to prepare the manganese oxide adsorbent.

[0035] The manganese oxide adsorbent is used for brine adsorption, and the brine passes through the manganese oxide adsorbent until it is saturated, and the concentration of lithium ions in the brine before and after adsorption is tested by an atomic absorption spectrophotometer. The test shows that the adsorption concentration of the adsorbent can reach the original brine More than 80% of the medium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com