Six-axis linkage numerical control polishing machine

A six-axis linkage, polishing machine technology, applied in the field of CNC polishing machines, can solve the problems of large physical consumption of workers, high rework rate, human injury, etc., to protect health and environmental sanitation, improve work efficiency, and prevent dust overflow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

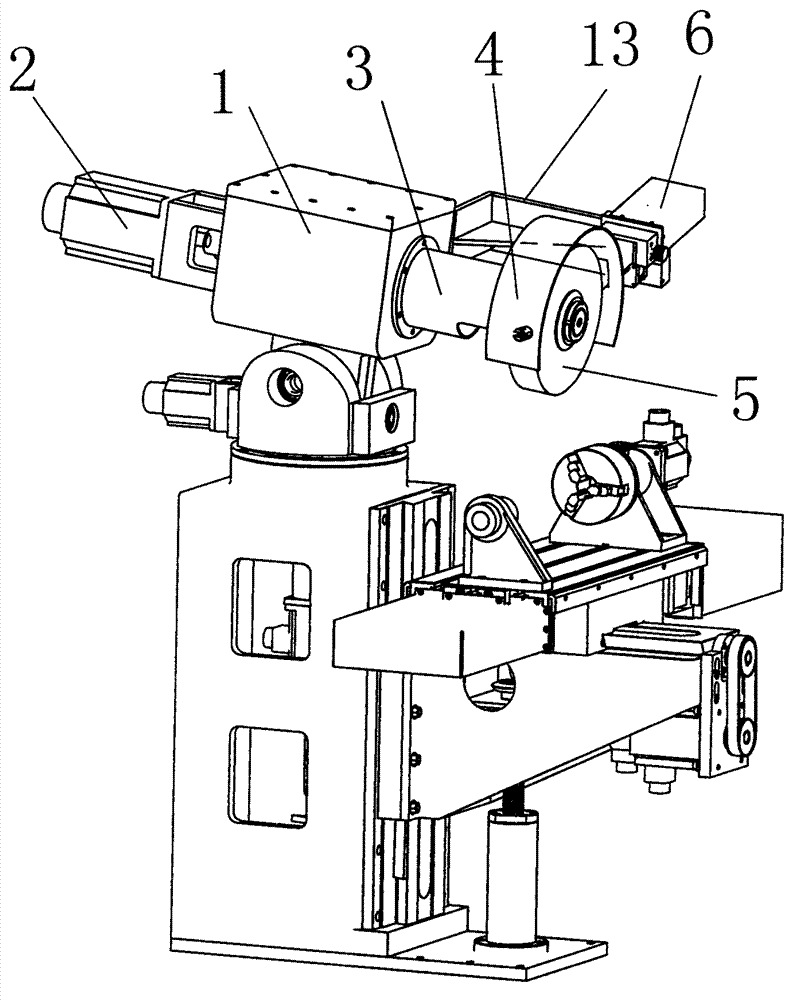

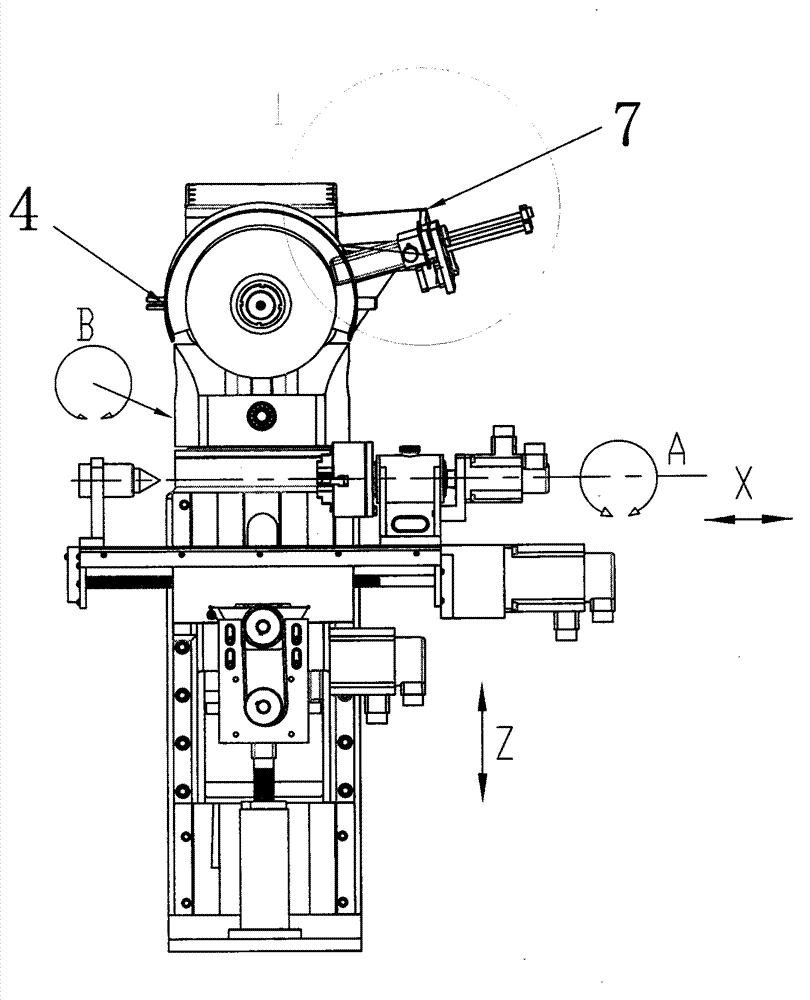

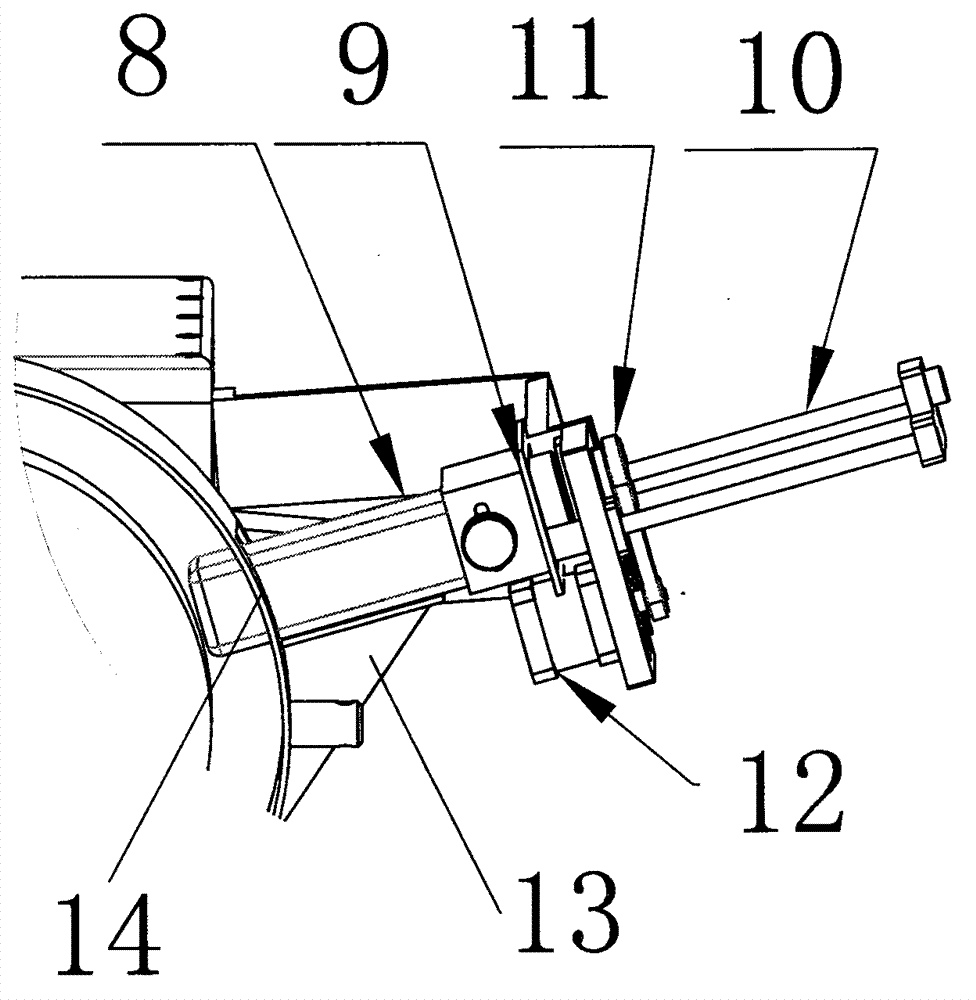

[0029] The six-axis linkage CNC polishing machine of the present invention applies the domestic advanced CNC servo system to realize six-axis linkage, that is, the basic movement of the X, Y, and Z axes, and the interpolation movement of the A, B, and C axes. , Free-form surface, relying on the high-speed rotation of the abrasive polishing wheel to quickly grind and polish the protruding part of the surface, so as to obtain a high-quality, high-precision surface.

[0030] The CNC polishing machine of the present invention expands the processing scope of the machine tool based on the principle of one machine with multiple functions. During the secondary development of the CNC servo system, the machine tool clamp attachment control unit interface (A-axis) is added, and the operation module is written in the CNC program to realize that there are clamps. Under the module mechanism, the number of clamping is reduced, and the outer surface of the geometric surface of the workpiece wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com