Sand blasting accessory and high-pressure slurry abrasive material jet injection system

An abrasive jet and jet system technology, applied in the fields of cutting, repairing, and slurry abrasive jet cleaning, can solve the problems of inability to quantitatively control the uniformity, limited pressure resistance of the pressure vessel, and limited jet pressure, so as to broaden the effective targeting and feasibility. Controllability, improve work efficiency, and not easy to block the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

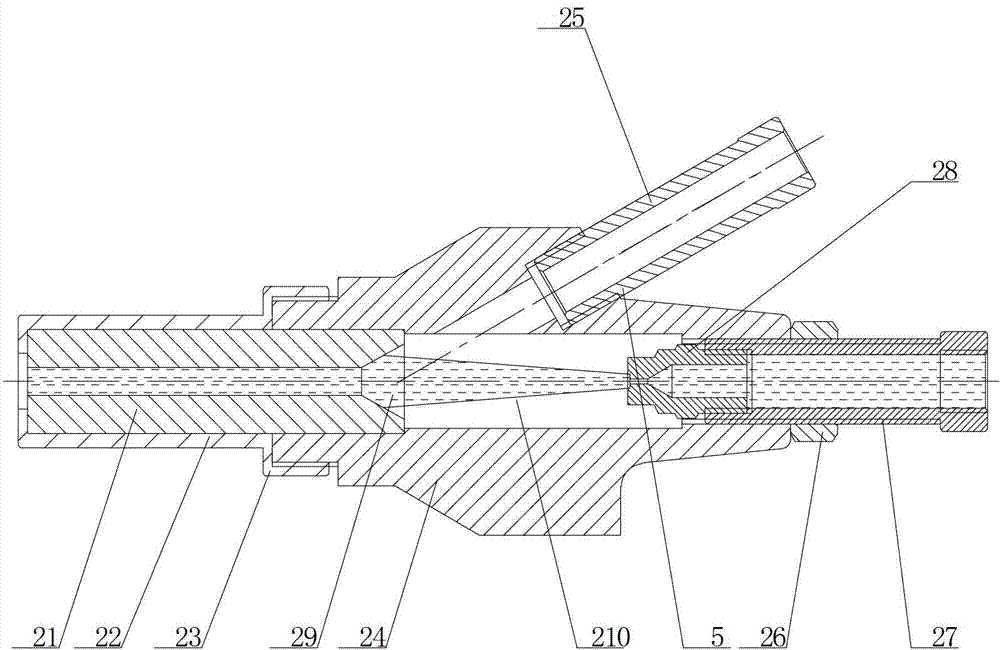

[0026] Such as figure 1 As shown, a sandblasting accessory for a high-pressure slurry abrasive jet injection system of the present invention includes a sandblasting accessory body 24, a high-pressure cylindrical water nozzle 28, a slurry-absorbing abrasive short pipe 25, and the sandblasting accessory body 24 A cavity is arranged inside, and the cavity includes a first cavity 29 and a second cavity 210, the first cavity 29 is a frustum-shaped cavity, and the second cavity 210 is a cylindrical cavity; The bottom surface of the circular platform body-shaped cavity 29 communicates with one end of the cylindrical cavity 210; Cavity; the slurry-absorbing body abrasive short tube 25 is arranged on the upper part of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com