Four-station compact robotic stacking system

A palletizing system and compact technology, applied in the field of material palletizing devices, can solve the problems of inconvenient operation and maintenance, large floor space, complicated mechanism, etc., and achieve the effect of compact structure, reduced floor space and simple maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

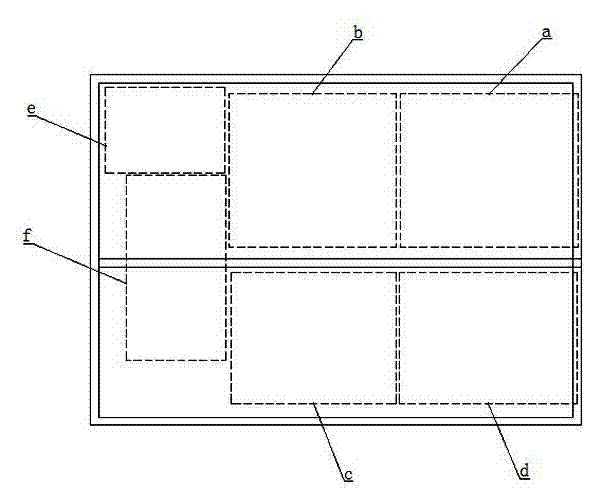

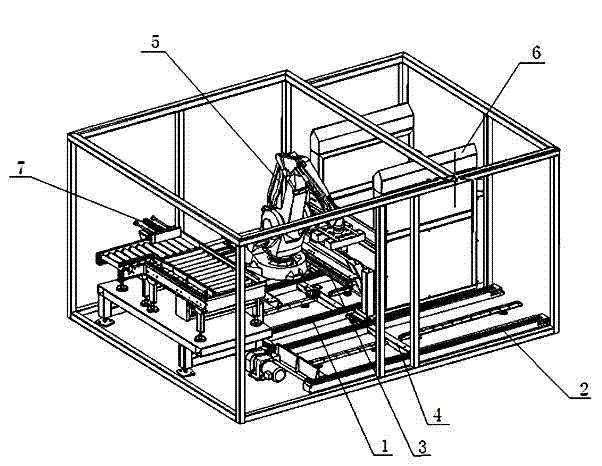

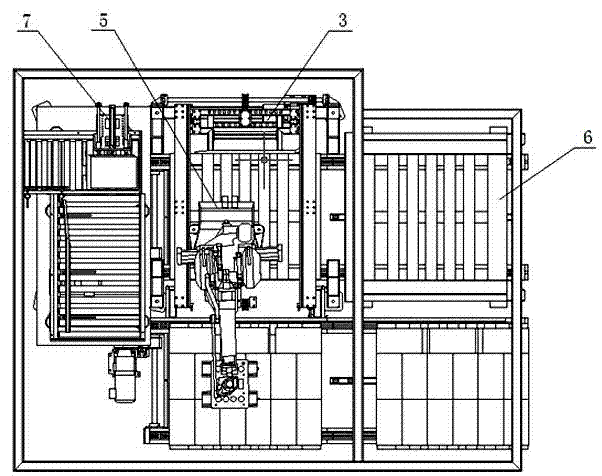

[0029] Such as figure 1 , 2 , 3 and 4, including product conveyor line, pallet conveyor line, sprocket conveyor belt A1, sprocket conveyor belt B2, empty pallet propulsion mechanism 3, pallet lifting mechanism 4, palletizing robot 5, empty pallet pallet feeder6.

[0030] Product conveying line, the product conveying line has a feeding conveying station e and a product grabbing station f, both the feeding conveying station e and the product grabbing station f adopt roller conveying, the front section of the feeding conveying station e The combination of driving roller and driven roller is used to convey the product, the rear section adopts the form of free roller, and the product grabbing station f adopts free roller. The manner of delivery here is only an example, which is not the focus of the present invention. The feeding conveying station e and the product grabbing station f adopt a 90° vertical layout, and a push mechanism 7 is set at the corner to push the product of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com