Anaerobic reaction device and processing method for 1,4-butanediol chemical wastewater

The technology of an anaerobic reaction device and treatment method is applied in the field of 1,4-butanediol chemical wastewater treatment device, which can solve the problems of high investment and operation cost of aerobic process, and achieve improved biological treatment performance and good operability , The effect of reducing the cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

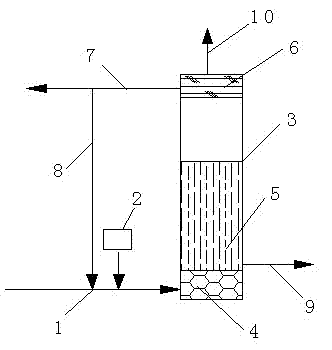

[0040] like figure 1 The shown 1,4-butanediol chemical wastewater anaerobic reaction treatment device 3 includes a water inlet distributor 4 arranged at the bottom of the device, an anaerobic sludge bed 5 in the middle and a three-phase separator 6 at the top, which are connected in sequence , the anaerobic sludge bed 5 is composed of a sludge bed composed of a large number of anaerobic microorganisms; the anaerobic reaction device 3 is sequentially connected to the sludge discharge pipe 9, the effluent discharge pipe 7 and the biogas discharge pipe 10 from the bottom up The water inlet distributor 4 is connected to the waste water inlet pipe 1, and the water outlet discharge pipe 7 is provided with an outlet return branch pipe 8 connected to the waste water inlet pipe 1.

[0041] In the anaerobic reaction device in this embodiment, a conditioning device is also provided between the wastewater inlet pipe 1 and the water inlet distributor 4 , and the conditioning device include...

Embodiment 2

[0048] 1,4-butanediol chemical wastewater enters the water inlet distributor. After adjusting the pH and adding nitrogen, phosphorus nutrients and trace elements, it is input into the anaerobic sludge bed. The COD of the incoming wastewater is 21,128mg / L. After conditioning, the pH value of the effluent from the water inlet distributor is 7.4, where COD:N:P is 420:5:0.8. The sludge concentration in the anaerobic sludge bed is 50g / L, the hydraulic retention time is 5 days, and the effluent reflux ratio of the anaerobic reactor is 150%.

[0049] The operating temperature of the entire process of wastewater in this embodiment is 30-32°C. After testing, the pH of the reaction device and the effluent was 6.7~7.0, and the COD was 786mg / L.

Embodiment 3

[0051] The 1,4-butanediolization waste water enters the water inlet distributor. After adjusting the pH and adding nitrogen, phosphorus nutrients and trace elements, it is input into the anaerobic sludge bed. The COD of the incoming wastewater is 19,879mg / L. 510:5:1.1. The sludge concentration in the anaerobic sludge bed is 70g / L, the hydraulic retention time is 2.8 days, and the effluent reflux ratio of the anaerobic reactor is 200%.

[0052] The operating temperature of the whole waste water process in this embodiment is 34-36°C. After testing, the pH of the reaction device and the effluent was 6.8~7.1, and the COD was 1280mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com