Synthesis and preparation method for probenecid sodium and probenecid potassium

A technology of probenecid sodium and probenecid potassium, which is applied in the preparation of sulfonic acid amide, organic chemistry and other directions, can solve the problems of less probenecid sodium and unsatisfactory results, and achieve the effect of easy process means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

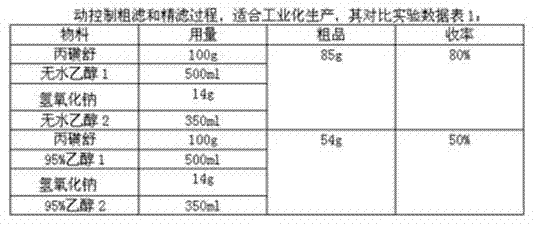

Examples

Embodiment 1

[0013] 1, the synthesis of probenecid sodium

[0014] 1.1 Reaction material

[0015] Probenecid 100g

[0016] Absolute ethanol 1 500ml (for dissolving probenecid)

[0018] Absolute ethanol 2 350ml (for dissolving sodium hydroxide)

[0019] 1.2 The process method is as follows:

[0020] Put a 2000ml three-necked flask with stirring, reflux condensing device and dropping funnel in a water bath, add probenecid and anhydrous ethanol in which probenecid is dissolved, start stirring, heat the water bath to 75-80°C, and keep this temperature, After the probenecid is completely dissolved, add the sodium hydroxide anhydrous ethanol solution that has been dissolved in advance at 70°C dropwise at a rate of about 5ml per minute, and continue to react for 15 minutes after dropping, then slightly lower the temperature to 50-60°C, and reflux to condense The tube is changed to a distillation condenser, and the temperature of the water bath is raised to 90-95...

Embodiment 2

[0036] 1, the synthesis of probenecid potassium

[0037] 1.1 Reaction material

[0038] Probenecid 100g

[0039] Absolute ethanol 1 500ml (for dissolving probenecid)

[0040] Potassium hydroxide 19.65g

[0041] 2 500ml absolute ethanol (for dissolving potassium hydroxide)

[0042] 1.2 The process method is as follows

[0043] Put a 2000ml three-necked flask with stirring, reflux condensing device and dropping funnel in a water bath, add probenecid and anhydrous ethanol in which probenecid is dissolved, start stirring, heat the water bath to 75-80°C, and keep this temperature, After the probenecid is completely dissolved, add the potassium hydroxide anhydrous ethanol solution that has been dissolved in advance at 70°C dropwise at a rate of about 5ml per minute, continue the reaction for 15 minutes after dropping, cool down slightly to 50-60°C, and reflux to condense The tube is changed to a distillation condenser tube, the water bath is heated to 90-95°C, concentrated, con...

Embodiment 3

[0059] 1, the synthesis of probenecid sodium

[0060] 1.1 Reaction material

[0061] Probenecid 1g

[0062] Absolute ethanol 1 5ml (for dissolving probenecid)

[0063] Sodium hydroxide 0.14g

[0064] Absolute ethanol 2 3.5ml (for dissolving sodium hydroxide)

[0065] 1.2 The process method is as follows:

[0066] Put a 2000ml three-necked flask with stirring, reflux condensing device and dropping funnel in a water bath, add probenecid and anhydrous ethanol in which probenecid is dissolved, start stirring, heat the water bath to 75-80°C, and keep this temperature, After the probenecid is completely dissolved, add the sodium hydroxide anhydrous ethanol solution that has been dissolved in advance at 70°C dropwise at a rate of about 5ml per minute, and continue to react for 15 minutes after dropping, then slightly lower the temperature to 50-60°C, and reflux to condense The tube is changed to a distillation condenser, and the temperature of the water bath is raised to 90-95°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com