Preparation method of boron-modified lubricating oil ashless dispersant

An ashless dispersant and boron-modified technology, used in lubricating compositions, additives, petroleum industry, etc., can solve problems such as poor thermal stability and storage stability, lack of anti-wear effect, etc., and achieve low production costs , good oxidation resistance, good wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 110 grams of polyisobutylene succinimide into a four-necked flask equipped with a mechanical stirrer, a thermometer, a ventilation device and a condensing reflux device, pass in argon, raise the temperature to 85-95 ° C, and add a particle size < 120 microns 2g of boric acid, then 1.2g of n-butanol and 1.2g of toluene were added, after 4 hours of reaction, the temperature was raised to 145°C, and the solvent was distilled for 4h to obtain the product borated polyisobutylene succinimide.

[0026] No unreacted boric acid slag was found after the product was filtered, and its physical and chemical properties are shown in Table 1.

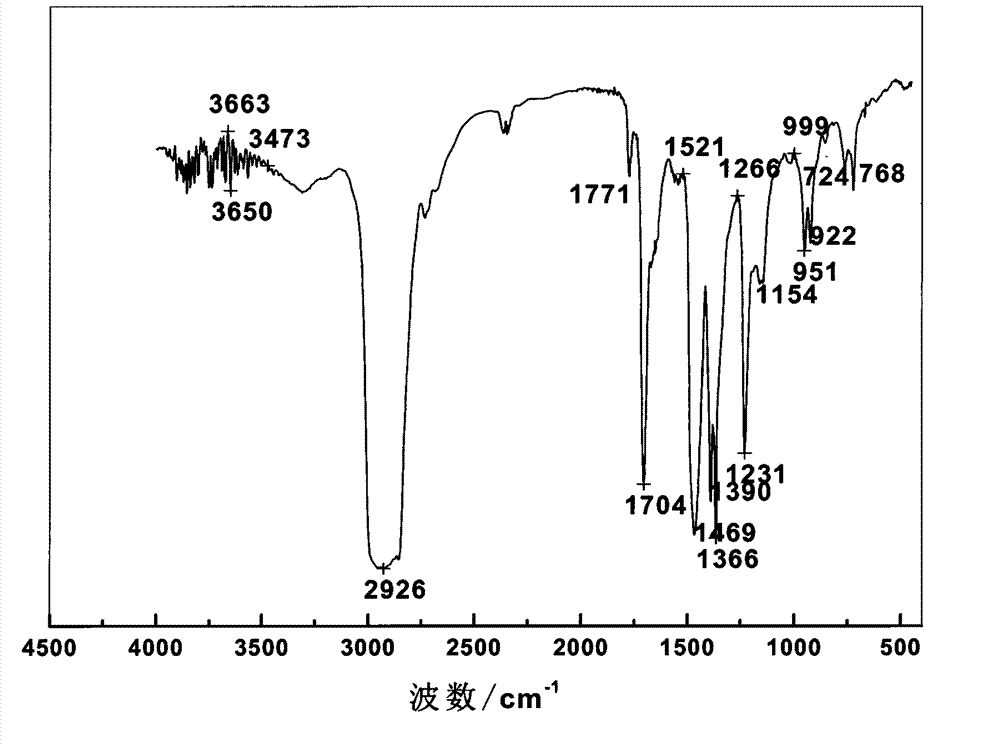

[0027] The resulting product is scanned by Fourier transform infrared, as shown in Figure 1, according to the infrared absorption theory, B-0, B-N are respectively at 1330cm -1 and 1380cm -1 Stretching vibration absorption occurs on the left and right, and the absorption is very strong. It can be seen from the figure that at 1366cm -1 and ...

Embodiment 2

[0029] Add 110 grams of polyisobutylene succinimide into a four-necked flask equipped with a mechanical stirrer, a thermometer, a ventilation device and a condensing reflux device, pass in argon, raise the temperature to 85-95 ° C, and add a particle size < 120 microns 1.4g of metaboric acid, then add 1.7g of n-butanol and 1.8g of toluene, after reacting for 4 hours, heat up to 145°C, distill the solvent for 4h, and obtain the product borated polyisobutylene succinimide. After the product is filtered, there is no Unreacted boric acid slag was found, and its physical and chemical properties are shown in Table 1.

Embodiment 3

[0031] Add 110 grams of polyisobutylene succinimide into a four-necked flask equipped with a mechanical stirrer, a thermometer, a ventilation device and a condensing reflux device, pass in argon, raise the temperature to 85-95 ° C, and add a particle size < 120 microns 9.3g of metaboric acid, then add 10.2g of n-butanol and 11.0g of toluene, after 4 hours of reaction, heat up to 145°C, and distill the solvent for 4h to obtain the product borated polyisobutylene succinimide. After the product is filtered, there is no Unreacted boric acid slag was found, and its physical and chemical properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com