Carbon layer materials with protection layer structure

A technology of protective layer and carbon layer, which is applied in the direction of metal material coating process, coating, layered products, etc., can solve the problem of reducing the speed of graphite film material receiving and dissipating heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

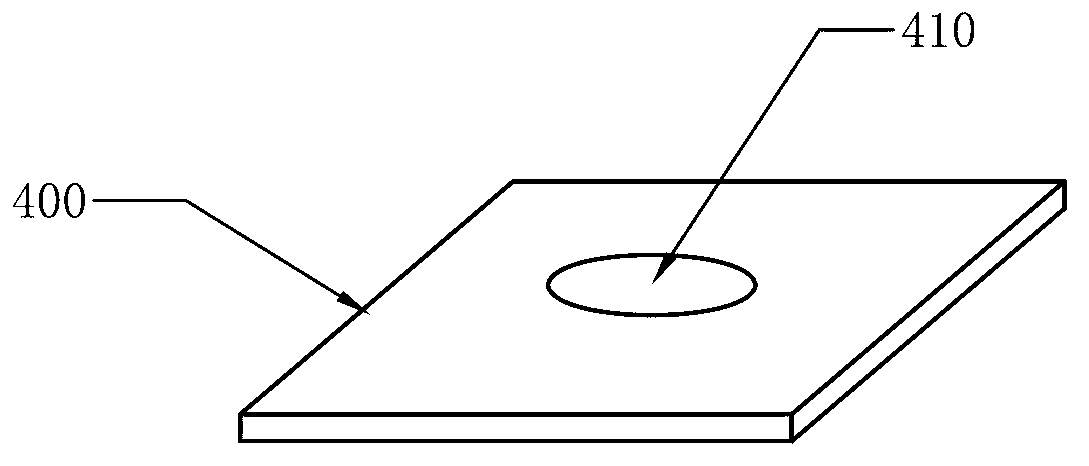

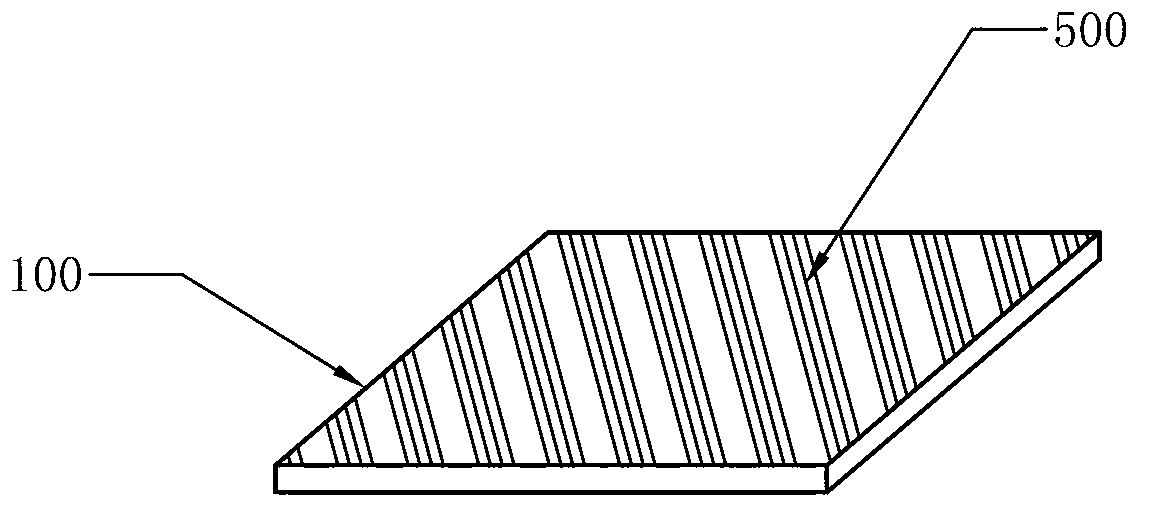

[0042] In the present invention, a thin film layer is formed on the carbon layer material by means of polymer vapor deposition, and the carbon layer material can be conveniently endowed with a protective layer structure by using the thin film layer.

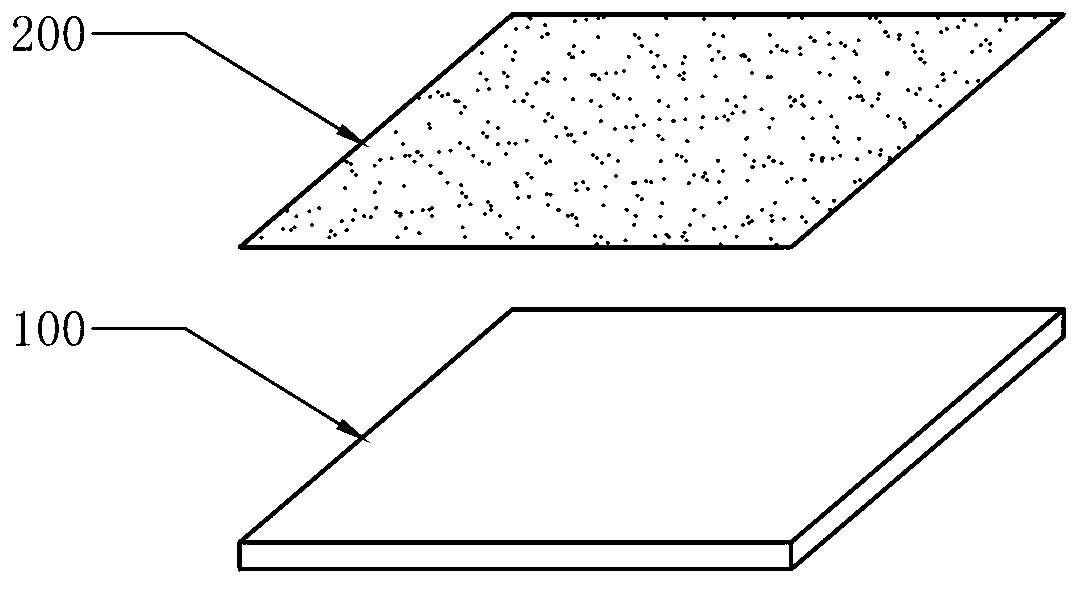

[0043] Specifically, the present invention provides a carbon layer material with a protective layer structure, which comprises:

[0044] The carbon layer material, preferably, is a material layer composed of graphite material and / or graphene. In addition, it can also be a layered structure composed of other carbon components, and of course it is not limited;

[0045] The polymer vapor deposition layer is a substance layer formed by performing polymer vapor deposition on the aforementioned carbon layer material, and its thickness is between 0.05-15 microns.

[0046] The preparation method of the material of the present invention will be described below in conjunction with specific examples.

[0047] Step 1, collecting the carbon ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap