Nanoparticle-reinforced wallpaper paste and preparation method thereof

A nano-enhanced, wallpaper technology, applied in the direction of paper, papermaking, fibrous fillers, etc., can solve the problems of poor mechanical properties, easy to be scratched, scrapped, etc., and achieve the effect of solving poor mechanical properties and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

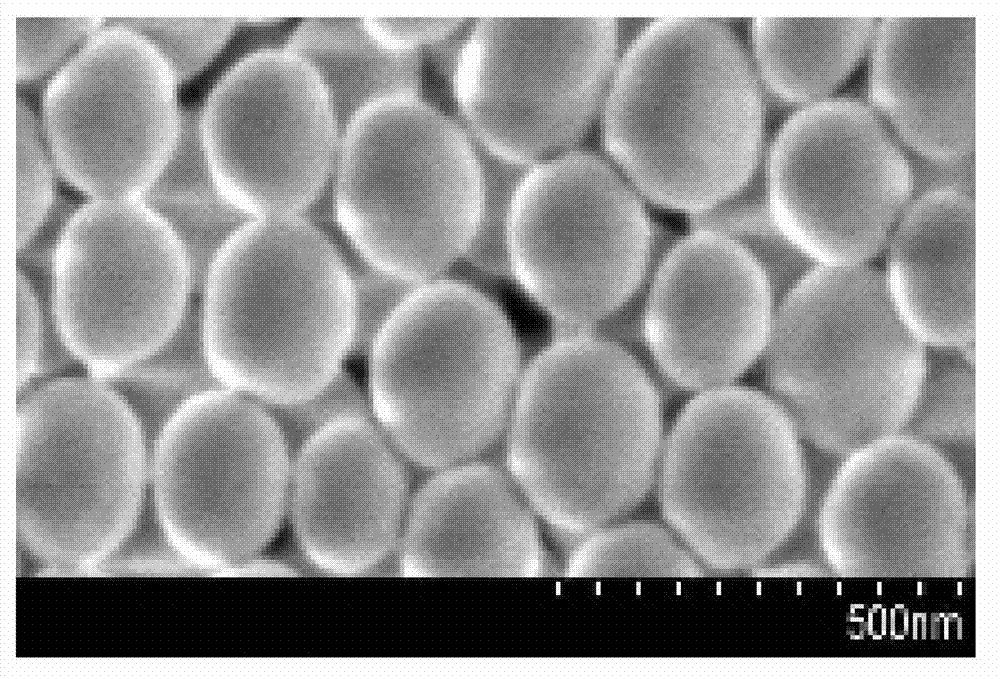

Embodiment 1

[0019] A paste for nano-enhanced wallpaper, which is composed of the following raw materials in parts by mass: 50 parts of plasticizer DOP, 100 parts of PVC paste resin P450, 3 parts of epoxy soybean oil, 3 parts of solvent oil D80, 2.6 parts of calcium zinc stabilizer, 2.2 parts of whipping agent AC-K, 46 parts of heavy calcium, 16 parts of titanium dioxide, 2 parts of modified nano silicon dioxide; described modified silicon dioxide is like this Preparation: Mix ethylene glycol, ammonia water, and water uniformly at a volume ratio of 1:0.8:0.8 to obtain a mixed solvent, mix ethyl orthosilicate and ethylene glycol at a volume ratio of 1:6, and Mix the mixture of tetraethyl orthosilicate and ethylene glycol with the mixed solvent at a volume ratio of 1:1.5, stir magnetically at 60-80°C for 6-8 hours to obtain a sol, and repeat 3-5 times for the obtained sol Centrifuge and wash with alcohol to obtain silica pellets, mix the obtained silica pellets with organic solvent DMF accor...

Embodiment 2

[0031] A paste for nano-enhanced wallpaper, which is composed of the following raw materials in parts by mass: 48 parts of plasticizer DOP, 100 parts of PVC paste resin P450, 3 parts of epoxy soybean oil, 3 parts of solvent oil D80, 2.5 parts of calcium zinc stabilizer, 2.6 parts of whipping agent AC-K, 50 parts of heavy calcium, 15 parts of titanium dioxide, 2 parts of modified nano-silica; Preparation: Mix ethylene glycol, ammonia water, and water at a volume ratio of 1:1:1 to obtain a mixed solvent, mix ethyl orthosilicate and ethylene glycol at a volume ratio of 1:8, and Mix the mixture of tetraethyl orthosilicate and ethylene glycol with the mixed solvent at a volume ratio of 1:2, stir magnetically at 60-80°C for 6-8 hours to obtain a sol, and repeat 3-5 times for the obtained sol Centrifuge and wash with alcohol to obtain silica pellets, mix the obtained silica pellets with organic solvent DMF according to the ratio of 1g:25ml to obtain a suspension, mix titanate couplin...

Embodiment 3

[0043]A paste for nano-enhanced wallpaper, which is composed of the following raw materials in parts by mass: 52 parts of plasticizer DOP, 100 parts of PVC paste resin P450, 3.5 parts of epoxy soybean oil, 3 parts of solvent oil D80, 3 parts of calcium-zinc stabilizers, 2.6 parts of foaming agent AC-K, 50 parts of heavy calcium, 18 parts of titanium dioxide, 3 parts of modified nano-silica; Preparation: Mix ethylene glycol, ammonia water, and water at a volume ratio of 1:1:1 to obtain a mixed solvent, mix ethyl orthosilicate and ethylene glycol at a volume ratio of 1:8, and Mix the mixture of tetraethyl orthosilicate and ethylene glycol with the mixed solvent at a volume ratio of 1:1.8, stir magnetically at 60-80°C for 6-8 hours to obtain a sol, and repeat 3-5 times for the obtained sol Centrifuge and wash with alcohol to obtain silica pellets, mix the obtained silica pellets with organic solvent DMF according to the ratio of 1g:22ml to obtain a suspension, mix titanate coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com