Local oxygen-enriched combustion transformation system for conventional circulating fluidized bed boiler with external bed

A circulating fluidized bed, oxygen-enriched combustion technology, applied in fluidized bed combustion equipment, fuels burned in a molten state, combustion methods, etc., can solve problems such as increased power generation costs, reduced power station efficiency, and reduced flue gas emissions. , the effect of improving combustion efficiency and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

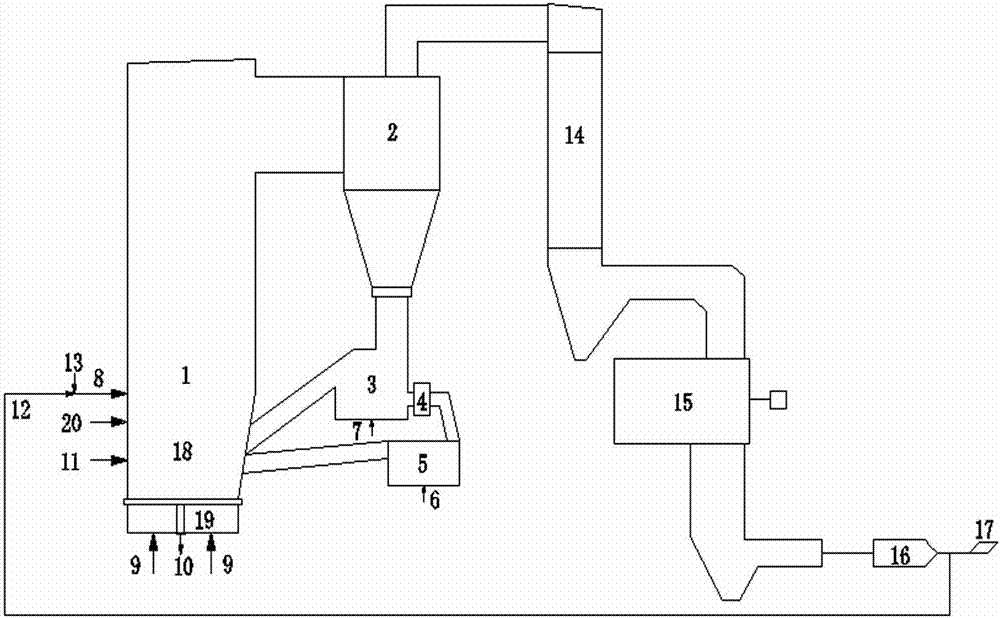

[0020] Such as figure 1 As shown, the present invention is a partial oxygen-enriched combustion transformation system for a conventional circulating fluidized bed boiler with an external bed. The reformed part is the secondary air 8, that is, the secondary air 8 adopts local oxygen-enriched combustion, while the primary air 9, the fluidized air 7 of the return feeder and the fluidized air 6 of the external bed still adopt conventional air combustion to avoid In the state of oxygen combustion, due to the increase of oxygen concentration, the required air flow rate decreases, resulting in insufficient fluidization power of the furnace 1, the feeder 3 or the external bed 5. The system composition after the boiler transformation is: the furnace 1 of the circulating fluidized bed boiler, the cyclone separator 2 and the rear heating surface 14 are connected in sequence, and the rear heating surface 14, the air preheater 15, the flue gas purification device 16 and the chimney 17 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com