Method for preparing pyrolysis oil and synthesis gases by pyrolysis of sludge

A technology of pyrolysis and cracking of oil, which is applied in the field of chemical engineering, can solve problems such as heating and difficulty, and achieve the effects of shortening time, saving energy consumption, and improving economic feasibility and technical feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

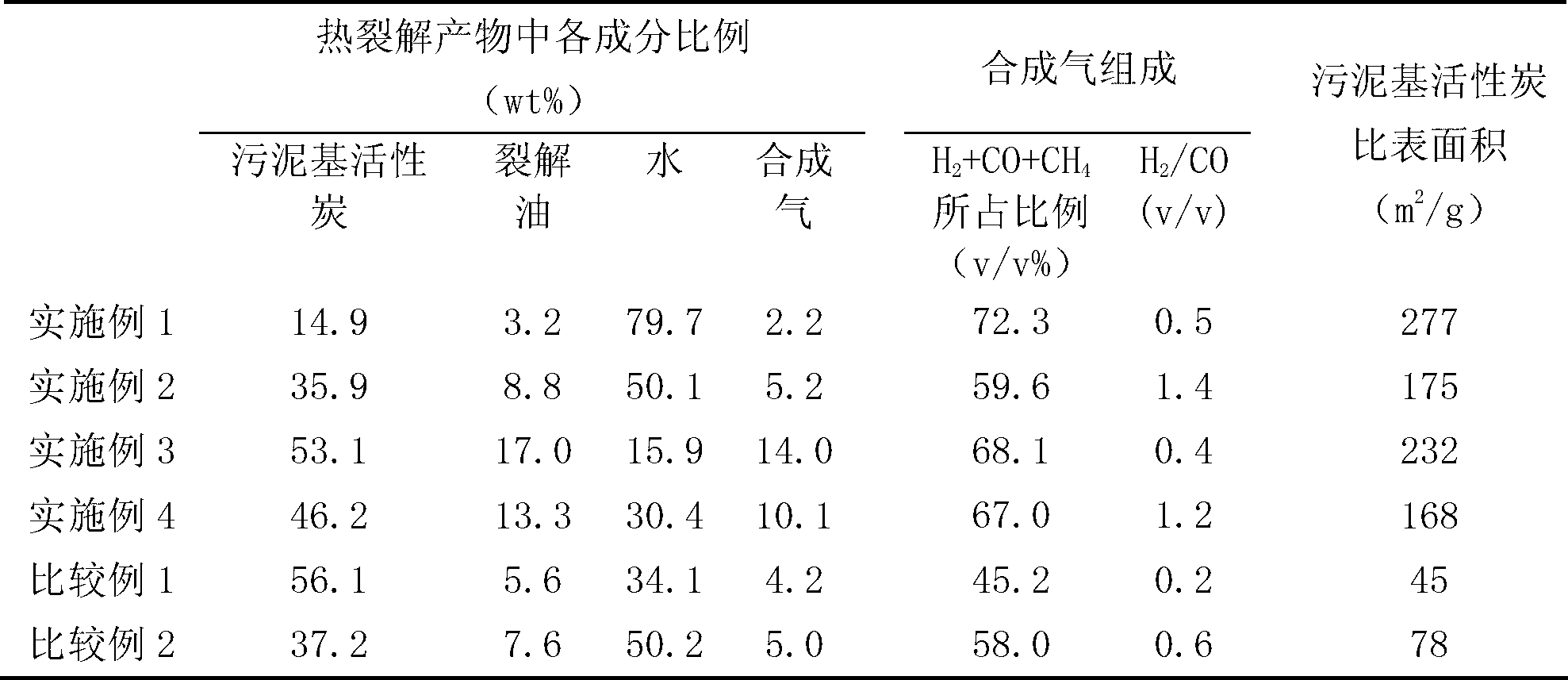

Embodiment 1

[0020] 100 parts by mass of dehydrated municipal domestic sludge (moisture content 85%) and 10 parts by mass of bamboo activated carbon powder and 5 parts by mass of Ni 2 o 3 Stir and mix the powder evenly, and send it into the microwave heating device. Before the start of microwave heating, feed nitrogen into the microwave heating device to replace the air in the original microwave heating device, and maintain a nitrogen flow rate of 1L / min per kilogram of sludge after the heating reaction starts. Using microwaves with a frequency of 2450MHz±50MHz, under the above inert reaction atmosphere conditions, the sludge heats up rapidly at a rate of about 40°C / min during the 100-400°C heating stage, and the final temperature rises to 700°C, and then continues heating for 10 minutes . The pyrolysis gas produced by microwave heating sludge is cooled to about 40°C through a condensing device, and the resulting water / cracking oil mixture and non-condensable gas are recovered separately...

Embodiment 2

[0022] Stir and mix 100 parts by mass of dehydrated municipal domestic sludge (water content 55%) with 5 parts by mass of coconut shell activated carbon powder and 10 parts by mass of CaO powder, and send them into a microwave heating device. Before the start of microwave heating, feed nitrogen into the microwave heating device to replace the air in the original microwave heating device, and maintain a nitrogen flow rate of 2L / min per kilogram of sludge after the heating reaction starts. Using microwaves with a frequency of 2450MHz±50MHz, under the above-mentioned inert reaction atmosphere conditions, the sludge is rapidly heated at a heating rate of about 30°C / min during the heating stage of 100-400°C, and the final temperature rises to 600°C, and then continues heating for 20 minutes . The pyrolysis gas produced by microwave heating sludge is cooled to about 30°C through a condensing device, and the resulting water / cracking oil mixture and non-condensable gas are recovered s...

Embodiment 3

[0024] With 100 parts by mass of dried sludge (moisture content 10%) and 20 parts by mass of the sludge-based activated carbon powder obtained in Example 1 and 2 parts by mass of Ni 2 o 3 Stir and mix the powder evenly, and send it into the microwave heating device. Before the start of microwave heating, feed nitrogen into the microwave heating device to replace the air in the original microwave heating device, and maintain a nitrogen flow rate of 3 L / min per kilogram of sludge after the heating reaction starts. Using microwaves with a frequency of 2450MHz±50MHz, under the above-mentioned inert reaction atmosphere conditions, the sludge is heated up rapidly at a rate of about 35°C / min during the heating stage of 100-400°C, and the final temperature rises to 650°C, and then continues heating for 15 minutes . The pyrolysis gas generated by microwave heating sludge is cooled to about 50°C through a condensing device, and the resulting water / cracking oil mixture and non-condensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com