Method and device for producing straw liquefied oil

A technology for carbonization of liquefied oil and straw, which is used in the preparation of liquid hydrocarbon mixtures and the petroleum industry. The effect of reducing and increasing the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

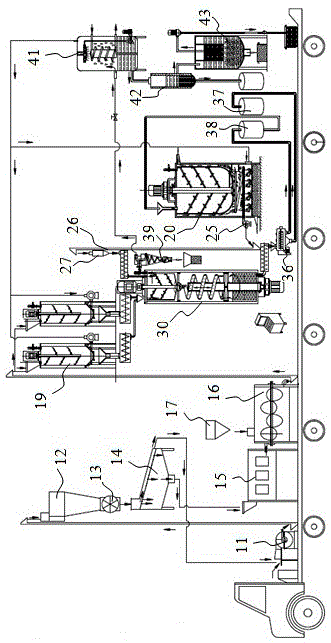

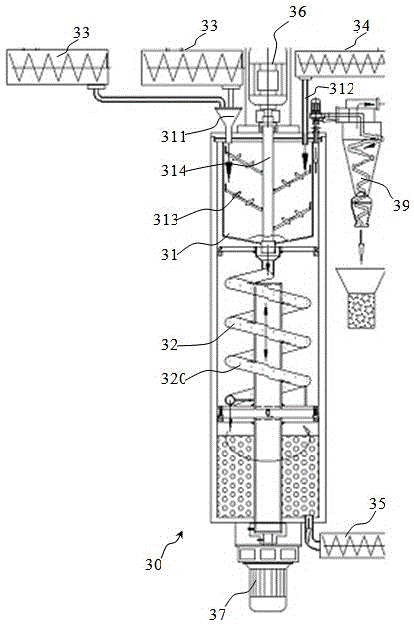

[0026] figure 1 It is a diagram of the device for producing straw liquefied oil according to the present invention, which also reflects the process flow of the present invention, including straw raw material processing flow, bed material processing flow, straw quick cracking gasification process and liquefied oil processing flow. The whole device is placed under the condition of vehicle, so that different places can be conveniently reached, which is convenient for the realization of local straw powder.

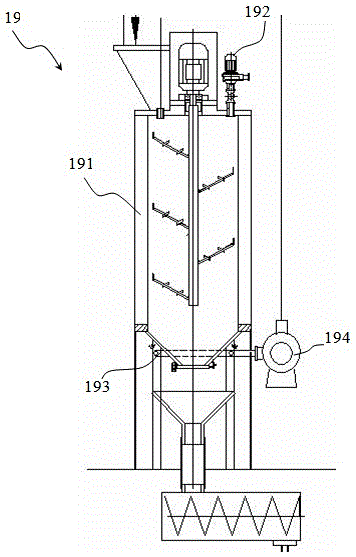

[0027] Straw raw material processing is carried out like this: the raw material stalk becomes the powdery straw of 1 ~ 3mm after being pulverized in the pulverizer 11, and this straw powder enters the material storage box 12 through the conveying pipeline, and the magnetic separator 13 pairs that are positioned at the material storage box 12 bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com