Method for preparing and conducting cold high pressure densifying on Cu wrapped Ba0.6K0.4Fe2As2 superconducting wire

A technology of superconducting wire and densification, which is applied in the field of preparation and modification of superconducting wire, can solve problems such as unfavorable formation of superconducting wire core, complicated and time-consuming process, and existing safety, so as to realize large-scale production and application, improve superconducting wire Conductivity, improve the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Preparation of Cu-coated Ba provided by the invention 0.6 K 0.4 Fe 2 As 2 A superconducting wire rod and a cold high-pressure densification method, comprising the steps of:

[0028] Step a. the Ba sheet with a purity of 99.5% to 99.9%, the K sheet with a purity of 95% to 99%, the Fe powder and the As powder with a purity of 99.9% to 99.99%, in an atomic ratio of 0.6:0.4:2: 2 Prepare it in the glove box and put it into a stainless steel ball mill tank. Ba flakes, K flakes, Fe powder and As powder are used as raw materials, and the excess of K is 5% to 10%;

[0029] Step b. Grinding the raw materials for 1 to 2 hours to form a mixed powder at a speed of 1425 to 1725 rpm;

[0030] Step c. Put the mixed powder into the Cu tube, and press and seal both ends of the Cu tube;

[0031] Step d. rolling and drawing the Cu tube containing the raw material powder into a wire rod; sintering the obtained wire rod at 750° C. to 850° C. for 24 to 30 hours under the protection of va...

Embodiment 1

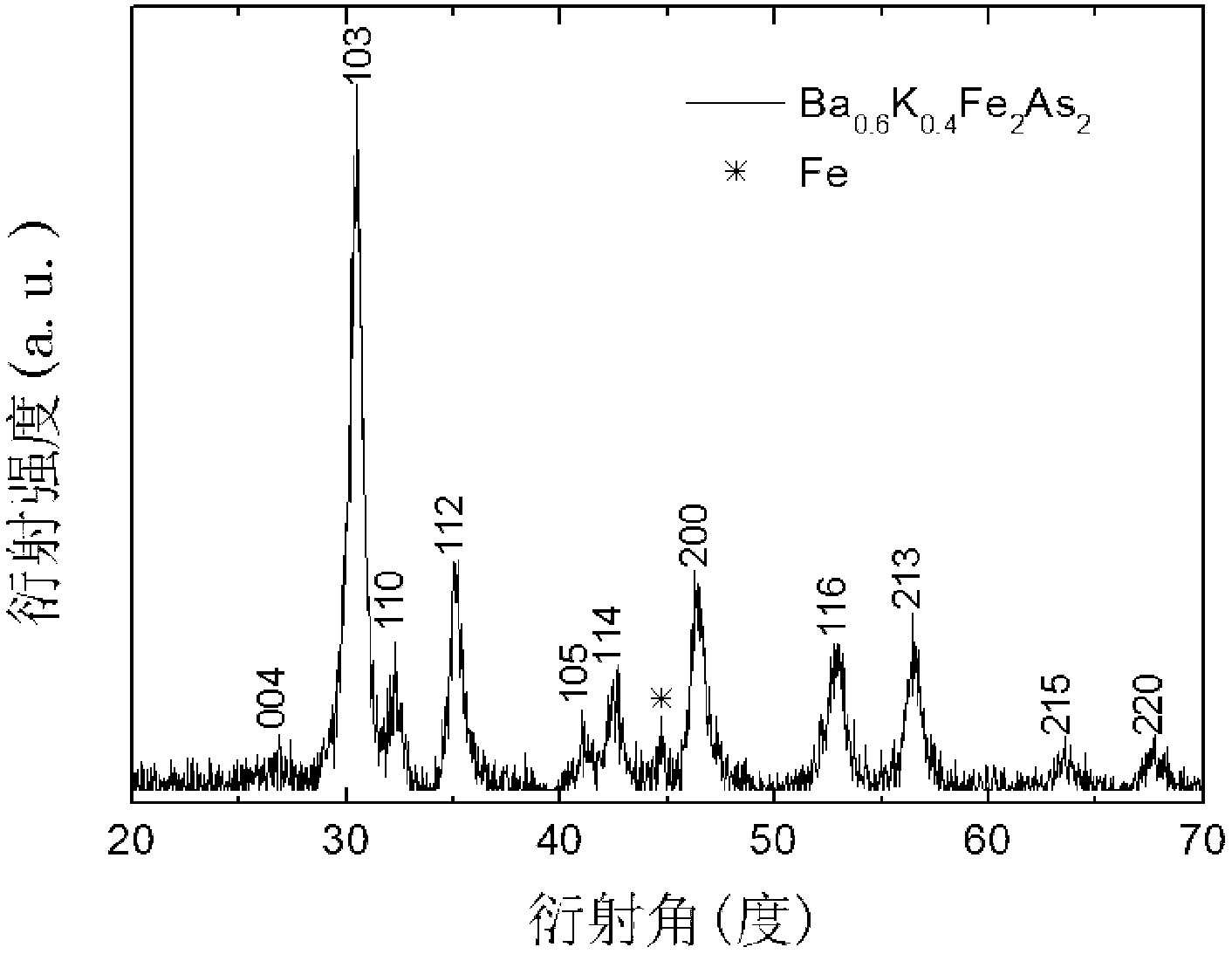

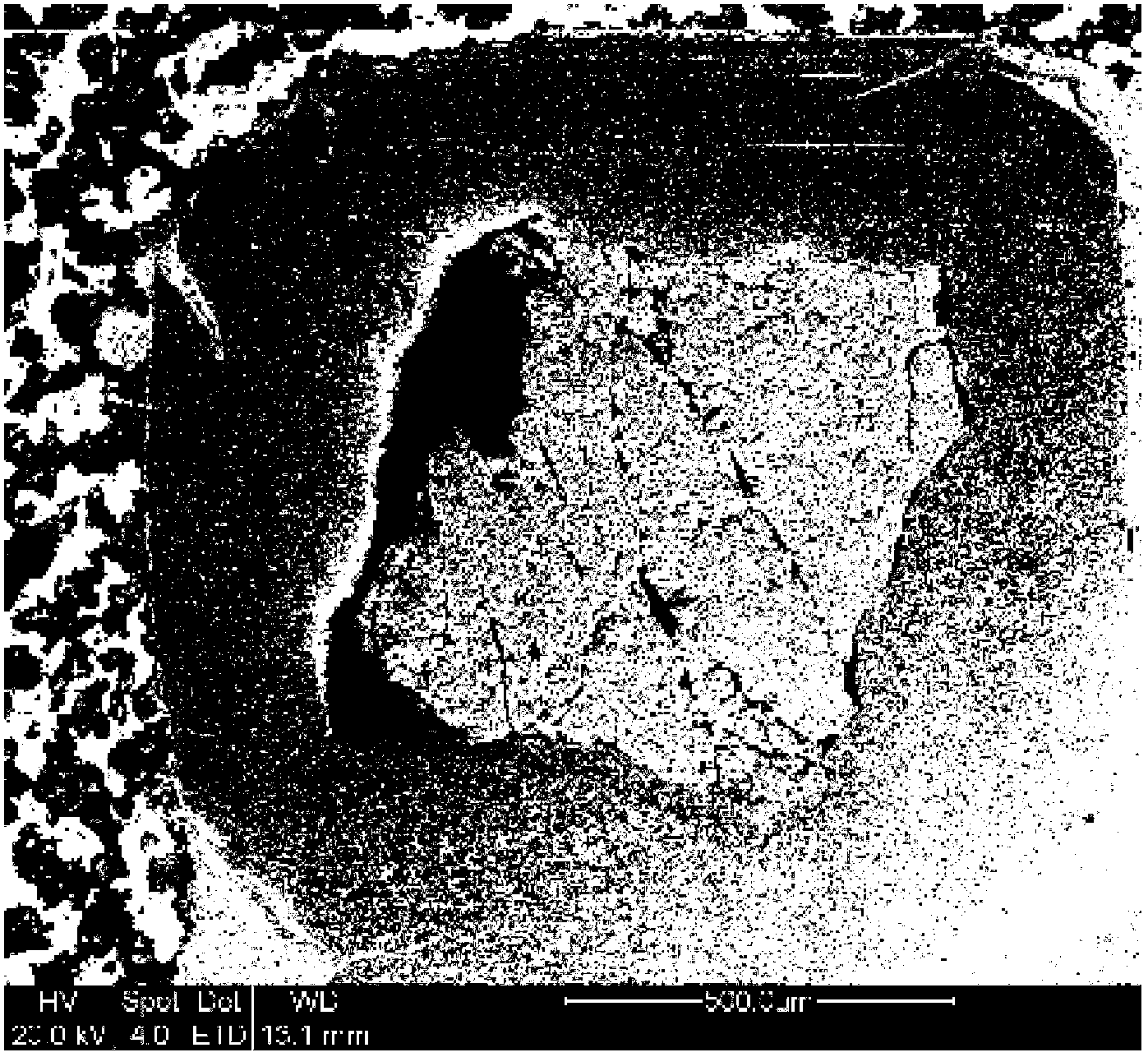

[0036] Mix Ba flakes (purity 99.9%), K flakes (purity 99%), Fe powder and As powder purity (purity 99.99%) in a glove box with an atomic ratio of 0.6:0.44:2:2 and put them into stainless steel In a ball mill jar. The atmosphere in the ball mill jar is high-purity Ar gas, which is sealed with a screw cap and an O-ring. Stainless steel balls are used as the ball milling medium, and the mass ratio of stainless steel balls to raw materials is 10:1. The raw material was milled for 2 hours at 1425 revolutions per minute. Put the powder obtained by the ball mill into the Cu tube, and press and seal both ends of the alloy tube. Using a hand-operated wire crimping machine, the Cu tube containing the raw material powder was directly rolled and drawn into a wire rod, and sintered under vacuum protection at 750 °C for 24 hours to obtain Ba 0.6 K 0.4 Fe 2 As 2 superconducting wire.

Embodiment 2

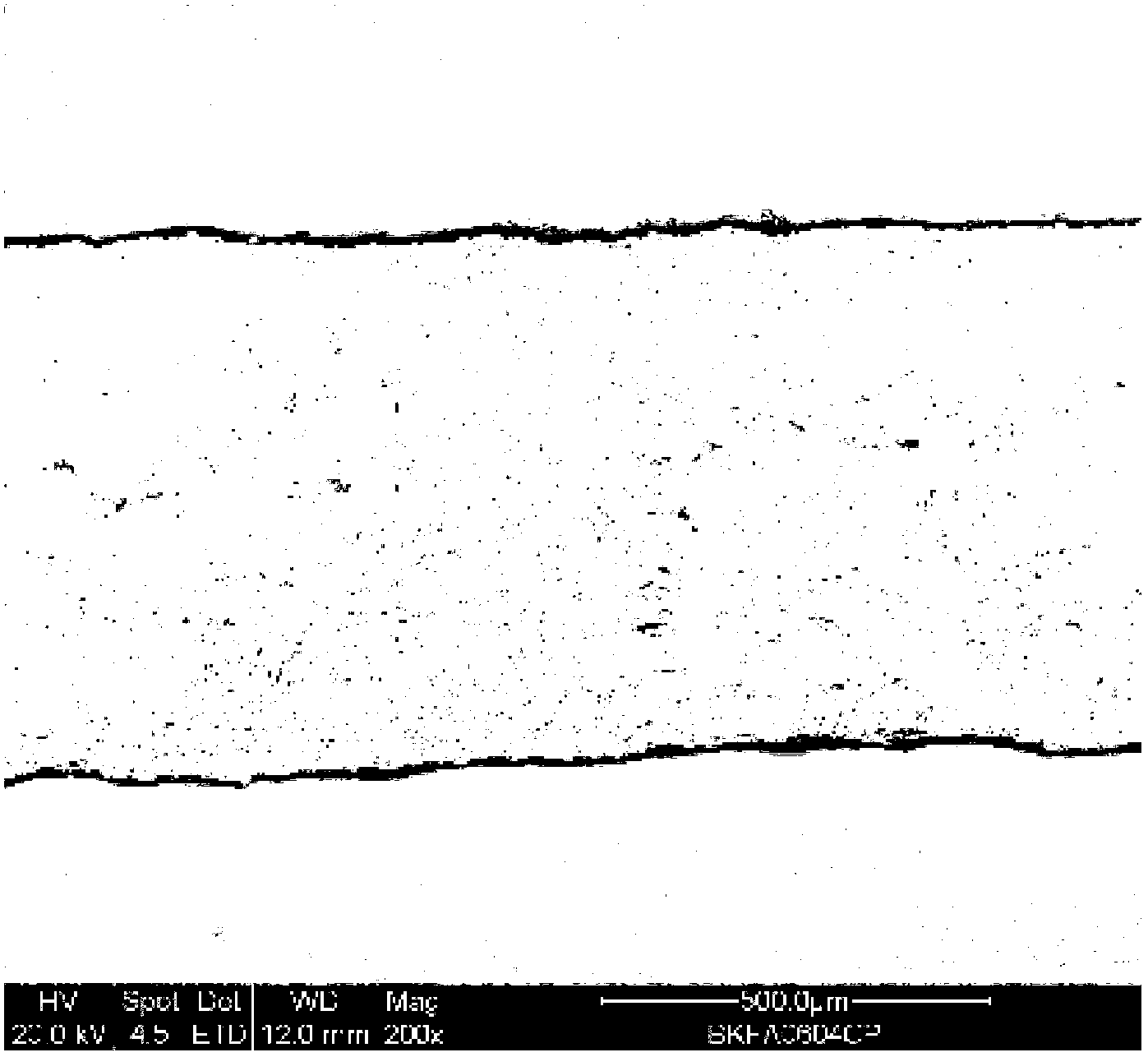

[0038] Mix Ba flakes (purity 99.9%), K flakes (purity 99%), Fe powder and As powder purity (purity 99.99%) in a glove box with an atomic ratio of 0.6:0.44:2:2 and put them into stainless steel In a ball mill jar. The atmosphere in the ball mill jar is high-purity Ar gas, which is sealed with a screw cap and an O-ring. Stainless steel balls are used as the ball milling medium, and the mass ratio of stainless steel balls to raw materials is 10:1. The raw material was milled for 2 hours at 1425 revolutions per minute. Put the powder obtained by the ball mill into the Cu tube, and press and seal both ends of the alloy tube. Using a hand-operated wire crimping machine, the Cu tube containing the raw material powder is directly rolled and drawn into a wire rod, which is placed in a cold and high-pressure densification device, and the pressure is 2 GPa in the vertical direction and 1 GPa in the horizontal direction. The wire obtained after densification was sintered under vacuum p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com