Preparation method of burley tobacco for simple and elegant fragrant cigarettes

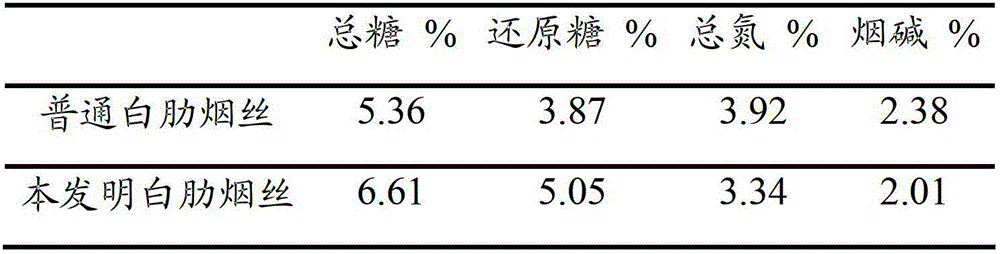

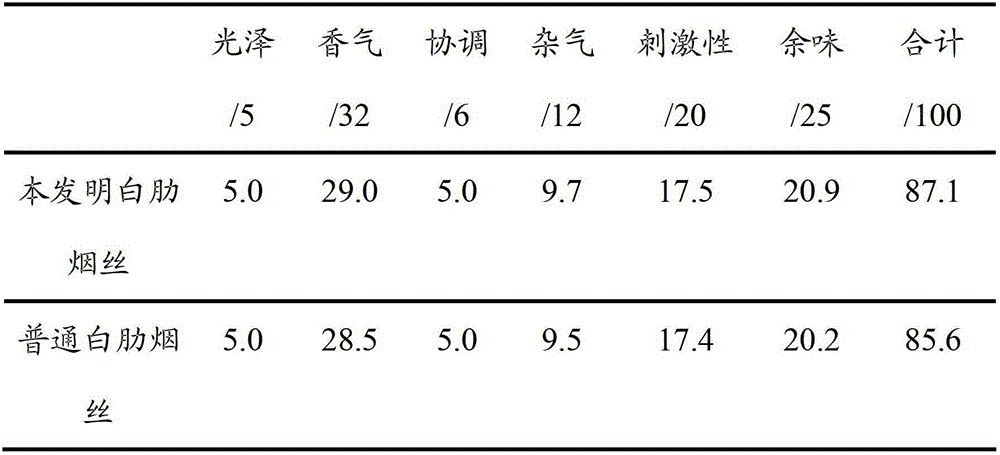

A technology of burley shredded tobacco and burley tobacco, which is applied in the preparation of tobacco, tobacco, application, etc., can solve the problems that affect the quality and characteristics of cigarettes, low sugar content, high nitrogen content, etc., and achieve good elasticity, obvious aroma, and improved The effect of flavor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Burley tobacco is placed in the dipping tank, and 95% edible alcohol solvent is added in a weight ratio of 1:12, containing 1.5% citric acid in the solvent, and the balance is water. Immerse for 30 minutes at a temperature of 50°C, then perform ultrasonic extraction for 30 minutes, then use a dehydration device to reduce the moisture content of burley tobacco to about 30%, carry out steam heating, store burley tobacco, slice and shred, add Feed liquid containing lactose and aspartic acid, the composition and weight percentage of the feed liquid are: 30% lactose, 10% aspartic acid, 60% water, the total amount of the feed liquid accounts for 8% of the weight of Burley shredded tobacco . Then drying and puffing are carried out to prepare shredded Burley tobacco. Burley shredded tobacco processed by this process has a mild taste, less miscellaneous gas, cleaner mouth, increased burnt sweetness, and more oily appearance and color.

Embodiment 2

[0031] Embodiment 2: Burley tobacco is placed in the dipping tank, and 75% edible alcohol solvent is added in a weight ratio of 1:15. The solvent contains 1.0% acetic acid, and the balance is water. Immerse for 40 minutes at a temperature of 60°C, then perform ultrasonic extraction for 40 minutes, then use a dehydration device to reduce the moisture content of burley tobacco to about 30%, perform steam heating, store burley tobacco, slice and shred, add A feed liquid containing xylose and asparagine, the composition and weight percentage of the feed liquid are: 50% xylose, 10% asparagine, 40% water, the total amount of the feed liquid accounts for 10% of the weight of Burley shredded tobacco . Then drying and puffing are carried out to prepare shredded Burley tobacco. Burley shredded tobacco processed by this process has a mild taste, less miscellaneous gas, cleaner mouth, increased burnt sweetness, and more oily appearance and color.

Embodiment 3

[0032] Embodiment 3: Burley tobacco is placed in the dipping tank, and 60% edible alcohol solvent is added in a weight ratio of 1:20. The solvent contains 1.0% citric acid and 1.0% acetic acid, and the balance is water. Immerse for 35 minutes at a temperature of 65°C, then perform ultrasonic extraction for 50 minutes, then use a dehydration device to reduce the moisture content of Burley tobacco to about 30%, perform steam heating, store Burley tobacco, slice and shred, add The feed liquid containing xylose and aspartic acid, the components and weight percentages of the feed liquid are: 40% xylose, 10% asparagine, and 50% water. The total amount of the feed liquid accounts for 12% of the weight of Burley shredded tobacco. %. Then drying and puffing are carried out to prepare shredded Burley tobacco. Burley shredded tobacco processed by this process has a mild taste, less miscellaneous gas, cleaner mouth, increased burnt sweetness, and more oily appearance and color.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com