Method for treating ammonia nitrogen wastewater

A technology for ammonia nitrogen wastewater and ammonia nitrogen, applied in chemical instruments and methods, degassed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low stripping efficiency, easy scaling of packing, high operating cost, etc. Achieve the effects of convenient operation, low operating cost and easy process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

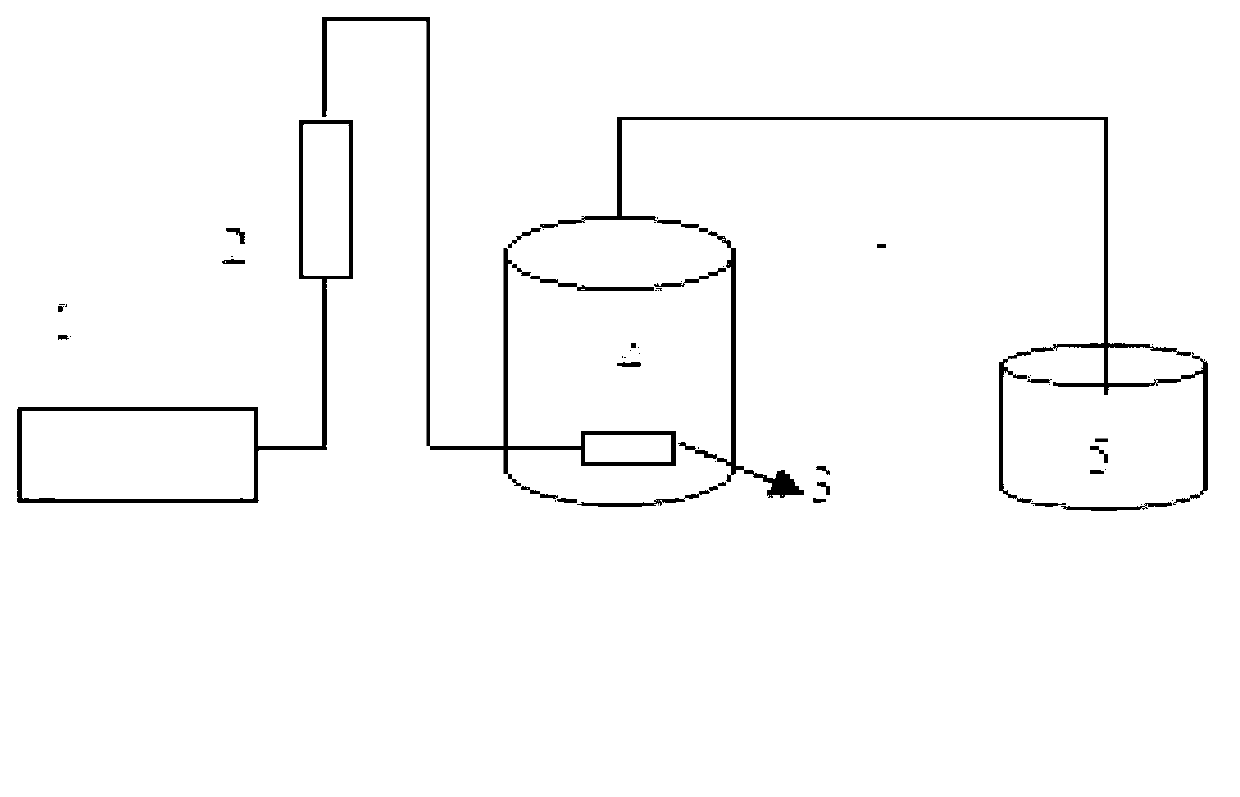

Image

Examples

Embodiment 1

[0023] Take industrial wastewater with an ammonia nitrogen concentration of 1000mg / L, add sodium hydroxide to adjust the pH to 12, add 0.1734g / L composite denitrification agent (the mass percentage of each component of the composite denitrification agent is: nano-iron 57.67%, polyethylene glycol Alcohol 200:42.33%), the waste water was added to the container, the gas-liquid ratio was adjusted to 1800:1, and the ammonia nitrogen removal rate reached 99.99% by ultrasonic blowing at room temperature for 60 minutes.

Embodiment 2

[0025] Take industrial wastewater with an ammonia nitrogen concentration of 2000mg / L, add sodium hydroxide to adjust the pH to 12, add 0.1567g / L composite denitrification agent (the mass percentage of each component of the composite denitrification agent is: nano-iron 63.83%, polyethylene glycol Alcohol 200:36.17%), the waste water was added to the container, the gas-liquid ratio was adjusted to 1800:1, and the ammonia nitrogen removal rate reached more than 99.21% by ultrasonic stripping at room temperature for 100 minutes.

Embodiment 3

[0027] Take industrial wastewater with an ammonia nitrogen concentration of 1000mg / L, add sodium hydroxide to adjust the pH to 12, add 0.19g / L composite denitrification agent (the mass percentage of each component of the composite denitrification agent is: nano-iron 53.06%, polyethylene glycol Alcohol 200:46.94%), the waste water was added to the container, the gas-liquid ratio was adjusted to 1400:1, and the ammonia nitrogen removal rate reached more than 98.45% by ultrasonic stripping at room temperature for 100 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com