High-density aquaculture oxygenation purification method and system

A technology for aquaculture and oxygen purification, which is applied in fish farming, energy wastewater treatment, oxidized water/sewage treatment, etc. It can solve the problems of unreasonable gas-water mixing, poor sterilization effect, and insufficient generation, so as to optimize gas-water The effect of mixing methods, increasing the breeding density, and increasing the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0027] Hereinafter, the present invention will be further described with reference to the drawings and specific implementations:

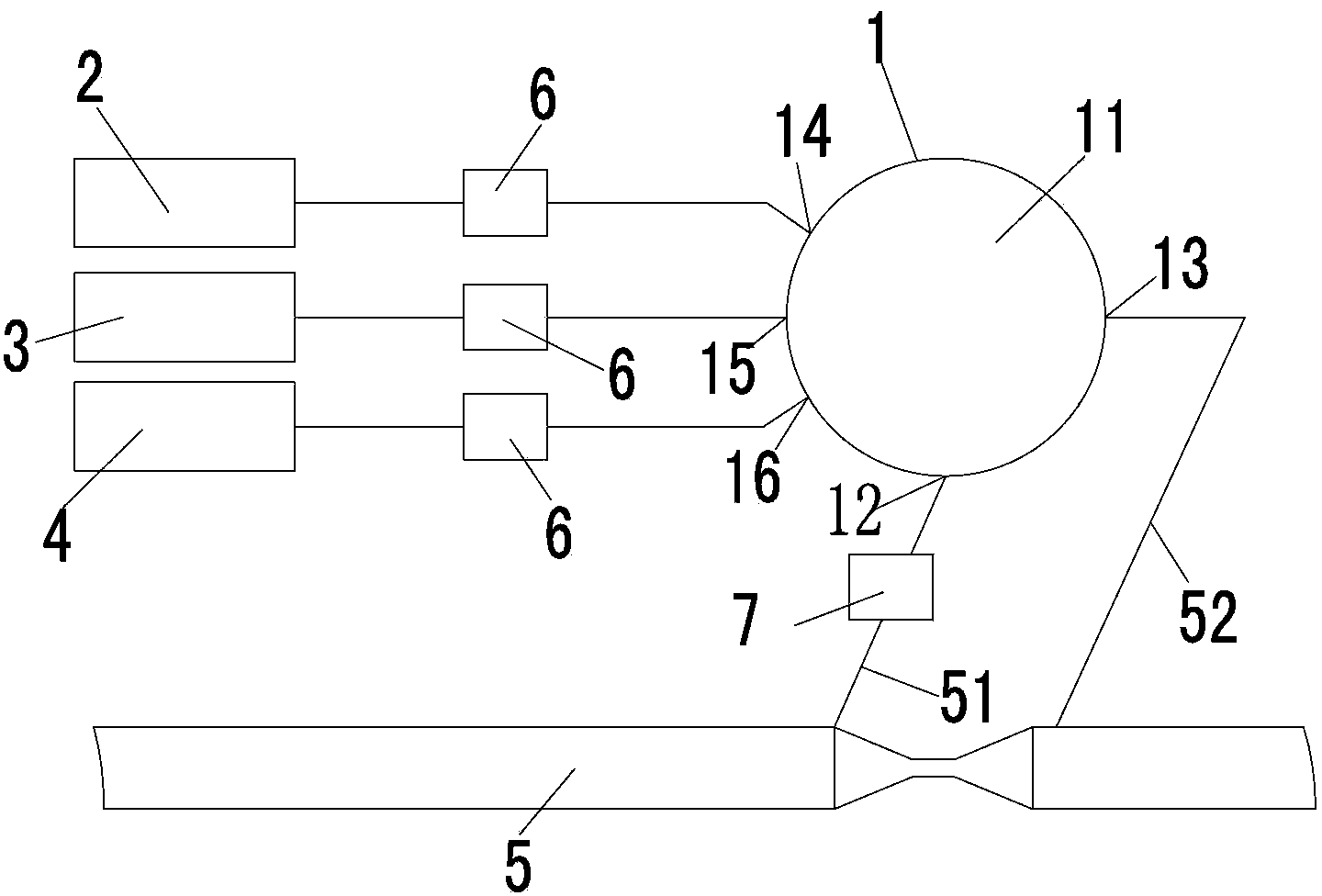

[0028] Reference figure 1 The oxygen purification system for high-density aquaculture described in this embodiment includes a gas-water mixer 1, an ozone generator 2, a singlet oxygen generator 3, a hydrogen peroxide generator 4 and a breeding water pipeline 5; The air-water mixer 1 is provided with an air-water mixing chamber 11, a water inlet 12, a water outlet 13, a first air inlet 14, a second air inlet 15 and a third air inlet 16 respectively communicating with the air-water mixing cavity 11 The gas-water mixing chamber 11 is connected to a high-pressure gas delivery device; the ozone generator 2 is connected to the first air inlet 14 of the gas-water mixer 1 through a metering pump 6, and the singlet oxygen generator 3 is connected through a metering pump 6 It is connected to the second air inlet 15 of the air-water mixer 1, and the hydrogen per...

specific Embodiment 2

[0039] The feature of this embodiment is: instead of setting a circulating pump, the siphon principle is used to input the aquaculture water to be treated in the aquaculture water pipe into the air-water mixer, and then the aquaculture water processed by the air-water mixer is introduced into the aquaculture water In the pipeline. Others are the same as the specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com