Slag stopping material, slag stopping method and combined technology method of slag stopping and slag splashing protection

A technology of slag splashing to protect the furnace and combined process, which is applied in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

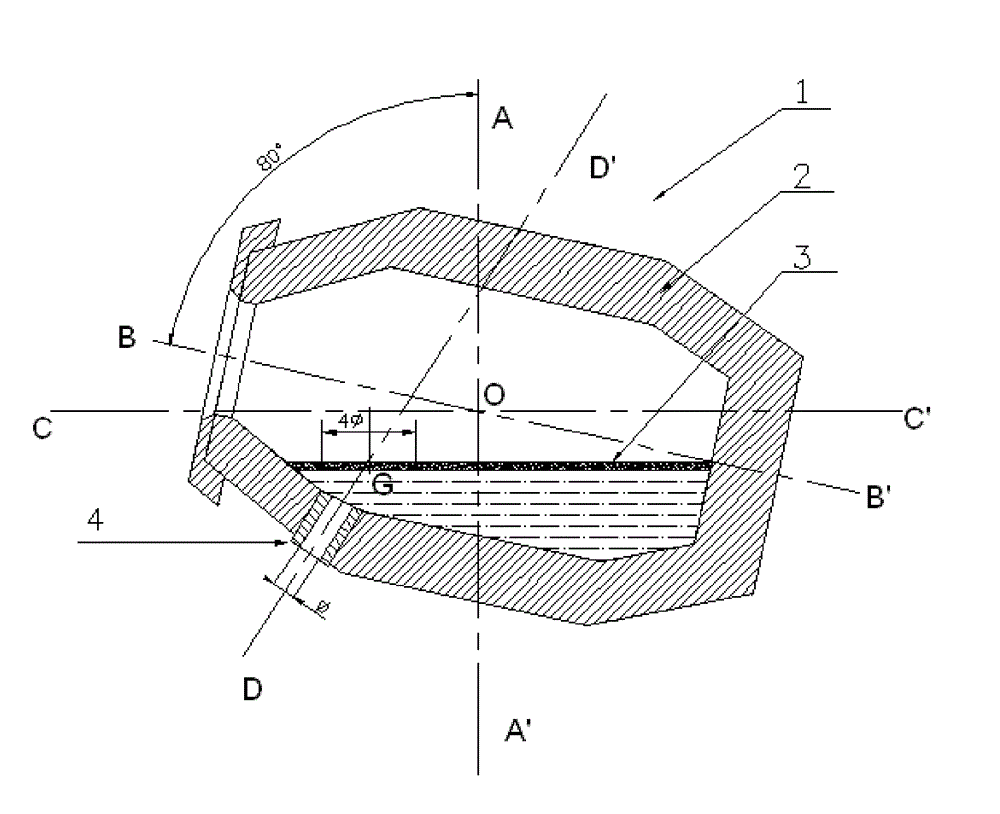

Image

Examples

preparation example Construction

[0081] (1) Preparation of slag blocking material

[0082] The sum of the mass percentages of CaO, MgO and C in the slag blocking material of the present invention accounts for more than 40% of the total mass of the slag blocking slag material, and the ignition rate is less than 47%, wherein the mass percentage content of C is more than 40%. It is higher than 25% of the total mass of the slag blocking material, and the balance is the unavoidable impurities in the slag blocking material raw materials, such as SiO 2 、Al 2 o 3 Wait. The carbon (C) refers to CO 3 2- other than carbon. The ignition loss refers to CaCO 3 , MgCO 3 , Ca(OH) 2 , Mg(OH) 2 CO in 3 2- and OH - and volatile matter, where CO 3 2- , OH - The ratio of volatile matter and volatile matter in ignition loss is determined by the selected raw materials. CaO and MgO in the slag blocking material may also exist in the form of calcium carbonate, magnesium carbonate or calcium magnesium carbonate (such a...

Embodiment 1

[0109] On a converter with a steel output of 300t in a steel plant, the slag retaining method of the present invention was used to carry out the slag retaining test, and the slag retaining ball was used to carry out the slag retaining test instead of the slag retaining method of the present invention. The smelted steel was Q195. A=5.15×10 is determined according to the comprehensive factors such as the bulk density of the slag material, the thickness of the slag layer and its density of the slag -3 , so it is determined from the formula (1) that the amount of the slag-blocking material added is 1546kg, the temperature of the slag-blocking slag material is 26°C, and the mass percentage of the powder contained in the slag-blocking slag material is 46%.

[0110] The chemical composition of the slag blocking material: CaO 9.5%, MgO 60.2%, C 19.9%, ignition loss 6.8%, and the balance is unavoidable impurities.

[0111] The specific operation process is as follows: put 1546kg of sl...

Embodiment 2

[0115] On a converter with a steel output of 180t in a steel plant, the slag retaining method of the present invention was changed from the original slag retaining ball to the slag retaining test, and the smelted steel was Q235. A=3.1×10 is determined according to the comprehensive factors such as the bulk density of the slag blocking material, the thickness of the slag layer and its density of the slag -3 , so that according to the formula (1), it is determined that the amount of slag-blocking slag added is 558kg, the temperature of slag-blocking slag is -46°C, and the mass percentage of powder contained in slag-blocking slag is 27%.

[0116] The composition of the slag blocking material: CaO 10.2%, MgO 47.9%, C 20.3%, ignition loss 17.5%, and the balance is unavoidable impurities.

[0117] The specific operation process is as follows: put 828kg of slag-stopping slag into the feeding trough, and when the tilting angle of the converter reaches 90°, put the slag-stopping slag i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com