High-strength bolt and processing method thereof

A technology of high-strength bolts and processing methods, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of plasticity and toughness that cannot reach high-strength bolts, and improve cold working performance, long service life, plasticity and toughness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

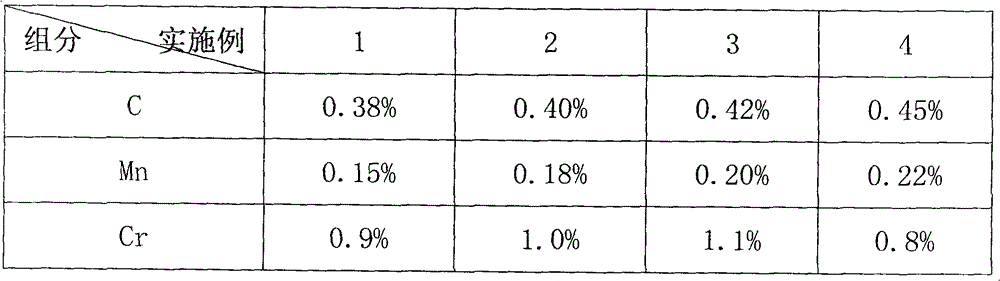

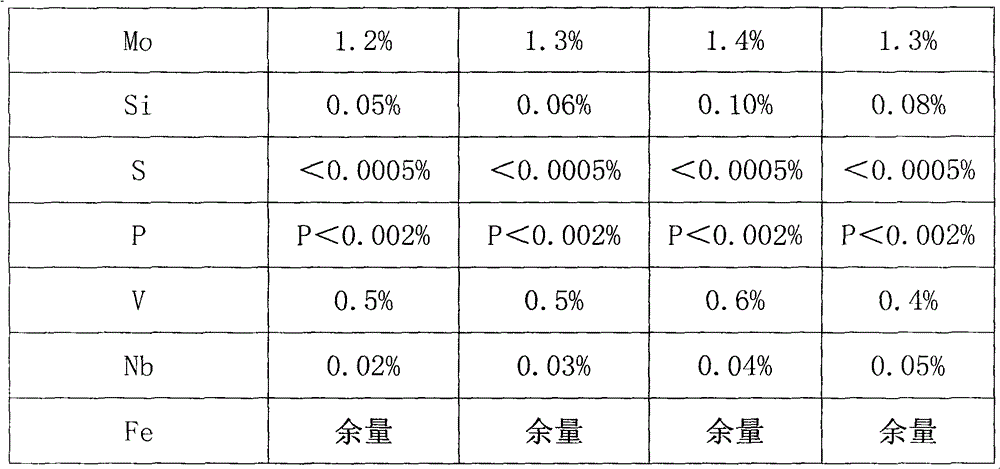

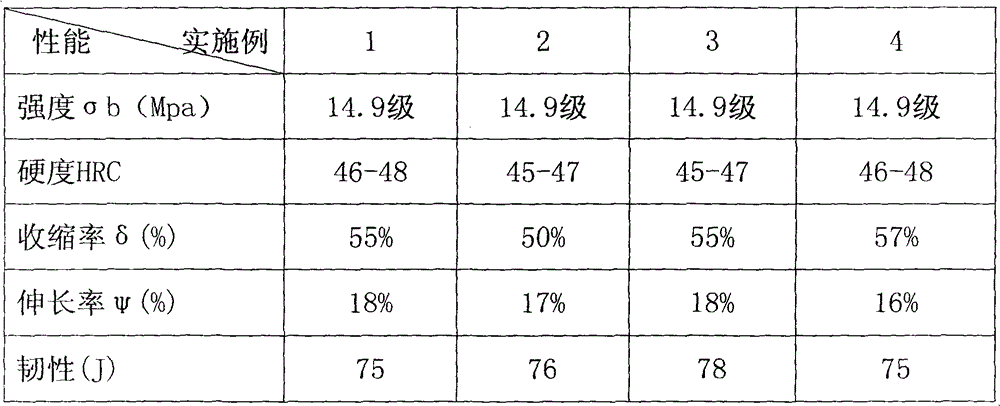

Embodiment 1

[0038]The high-strength bolt steel of Example 1 in Table 1 is selected for its chemical composition and mass percentage ratio. First, it is subjected to spheroidizing annealing treatment, pickling and derusting before being put into the furnace, and then enters the spheroidizing furnace. In order to avoid decarburization after spheroidizing annealing , the raw material is cooled slowly after 760°C and uniform temperature for 6 hours, then cut the raw material to the length required by the bolt, put the raw material into the mold cavity in the cold state, and cold extrude the raw material to form the head required by the bolt The cold-headed extruded bolt rough product of the head and rod; the above-mentioned cold-headed bolt rough product is quenched with quenching oil in a continuous heat treatment furnace at a temperature of 950 ° C, the holding time is 80 minutes, and then tempered at 550 ° C Treatment, holding time 2.5 hours; through quenching and tempering treatment, the b...

Embodiment 2

[0041] The high-strength bolt steel of Example 2 in Table 1 is selected for its chemical composition and mass percentage distribution ratio, and is first subjected to spheroidizing annealing treatment, pickling and rust removal before being put into the furnace, and then enters the spheroidizing furnace, in order to avoid decarburization after spheroidizing annealing , the raw material is cooled slowly after 780°C and uniform temperature for 5 hours, then cut the raw material to the length required by the bolt, put the raw material into the mold cavity in the cold state, and cold extrude the raw material to form the head required by the bolt Cold-headed extruded rough bolts at the head and shank; the above-mentioned cold-headed rough bolts are quenched with quenching oil in a continuous heat treatment furnace at a temperature of 940 ° C, the holding time is 100 minutes, and then tempered at 600 ° C Treatment, heat preservation time for 2 hours; through quenching and tempering t...

Embodiment 3

[0044] The high-strength bolt steel of Example 3 in Table 1 is selected for its chemical composition and mass percentage ratio. First, it undergoes spheroidizing annealing treatment, pickling and rust removal before entering the furnace, and then enters the spheroidizing furnace. In order to avoid decarburization after spheroidizing annealing , the raw material is cooled slowly after 750°C and uniform temperature for 8 hours, then cut the raw material to the length required by the bolt, put the raw material into the mold cavity in the cold state, and cold extrude the raw material to form the head required by the bolt Cold-headed extruded rough bolts at the head and shank; the above-mentioned cold-headed rough bolts are quenched with quenching oil in a continuous heat treatment furnace at a temperature of 980°C, the holding time is 60 minutes, and then tempered at 580°C Treatment, heat preservation time for 2 hours; through quenching and tempering treatment, the bolts can reach ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com