Method for applying petrochemical exhausted lye to semidry-method flue gas desulfurization

A petrochemical and waste lye technology, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, to achieve the effects of reducing treatment costs, occupying a small area, and improving flue gas desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

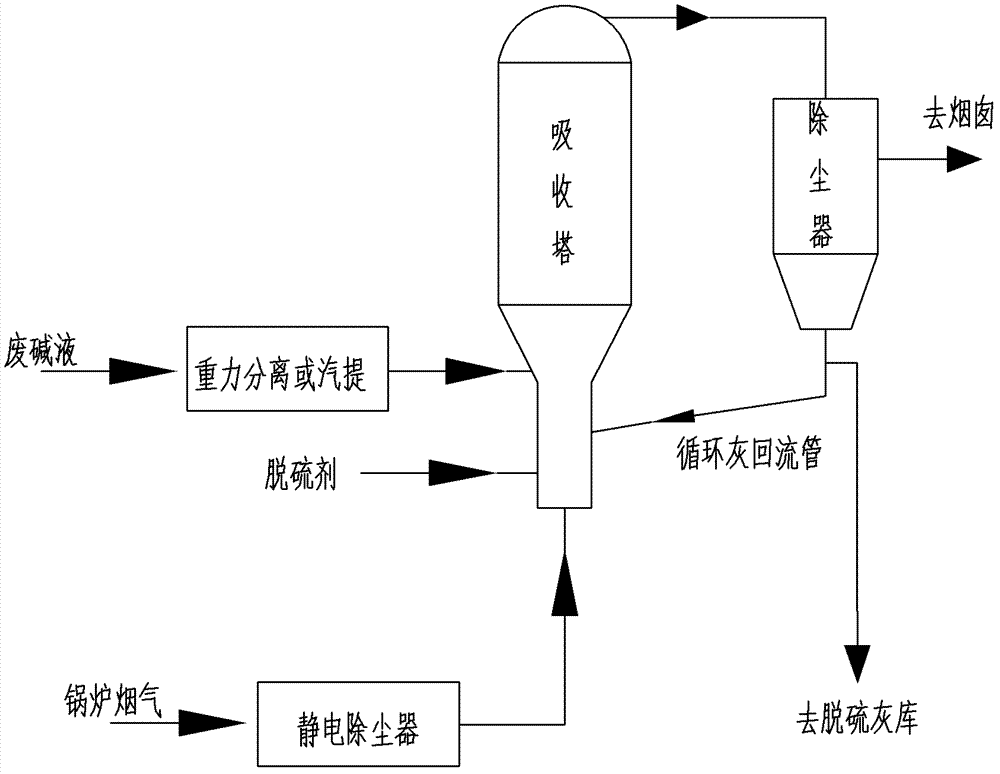

[0027]The olefin waste lye is settled by gravity for 24-48 hours, and the oily substances and suspended solids are separated and removed. Spray the pretreated waste lye and desulfurizer into the absorption tower with spray nozzles in the middle and upper part of the absorption tower, and at the same time, pass the boiler flue gas that has removed most of the dust in the flue gas through electrostatic dust removal into the absorption tower At the bottom, after being accelerated by the Venturi structure at the bottom of the absorption tower, it enters the absorption tower and flows from bottom to top in the tower. In this process, the pretreated waste caustic soda is driven into the absorption tower by the corrosion-resistant pump and spray nozzle, sprayed from top to bottom from the sprayer, and directly contacts with the flue gas in a turbulent state, fully reacting to reach SO removal from flue gas 2 the goal of.

[0028] In this example, the flow rate of boiler flue gas is...

Embodiment 2

[0031] In this example, boiler flue gas SO 2 The concentration is 2100~3900mg / Nm 3 . When the injection amount of waste lye is 4.0t / h, and the desulfurization agent is sodium hydroxide, and the dosage is 1.5t / h, the SO in the flue gas 2 Emission concentration 500~600mg / Nm 3 , The desulfurization rate is 75% to 85%. The color of desulfurization gray is dark gray, and the main component is Na 2 S 2 o 3 ·5H 2 O, Na 2 SO 3 、Na 2 CO 3 ·H 2 O, the density is 0.7626Kg / dm 3 . Other method steps are with embodiment 1.

Embodiment 3

[0033] In this example, the alkali-containing waste water is the waste lye produced by the vinyl chloride plant, and most of the organic matter is removed by rectification or stripping. After pretreatment, the dichloroethane content of the alkali-containing wastewater is less than or equal to 1 μg / g.

[0034] The flow rate of boiler flue gas to the bottom of the absorption tower is 40-50Nm 3 / h,SO 2 The concentration is 2600~4300mg / Nm 3 . When the amount of waste lye injected from the middle and upper part of the absorption tower is 6.0t / h, and the amount of sodium hydroxide injected is 0.8t / h, the SO in the flue gas 2 Emission concentration 400~500mg / Nm 3 , The desulfurization rate is 80% to 90%.

[0035] The color of desulfurization gray is dark gray, and the main component is Na 2 S 2 o 3 ·5H 2 O, Na 2 SO 3 、Na 2 CO 3 ·H 2 O, the density is 0.8434Kg / dm 3 . Other method steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com