Methods of Improving the Dryness of Biomass Sludge

A biomass and sludge technology, which is applied in biological sludge treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of not being able to meet normal production, dripping on the road surface, and low dryness of sludge, and achieve increased Machine operation efficiency, effect of preventing lock-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

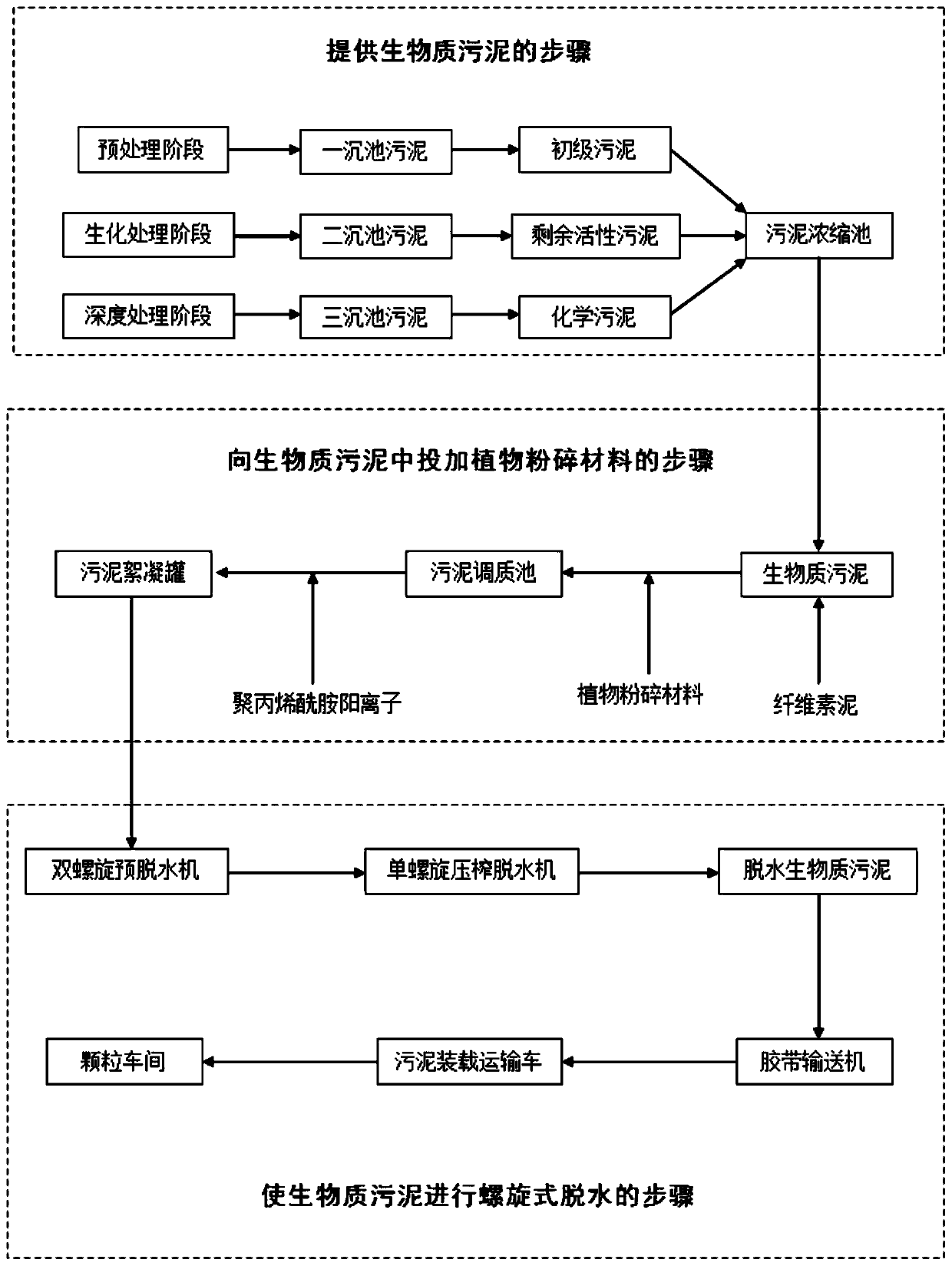

Method used

Image

Examples

Embodiment 1

[0042] (1) Add plant pulverized material and cellulose mud to the biomass sludge to carry out conditioning of the biomass sludge;

[0043] (2) Then add polyacrylamide cationic solution and mix to carry out biomass sludge flocculation;

[0044] (3) Finally, the double-screw pre-dehydration treatment is performed, and then the single-screw pressing dehydration treatment is obtained.

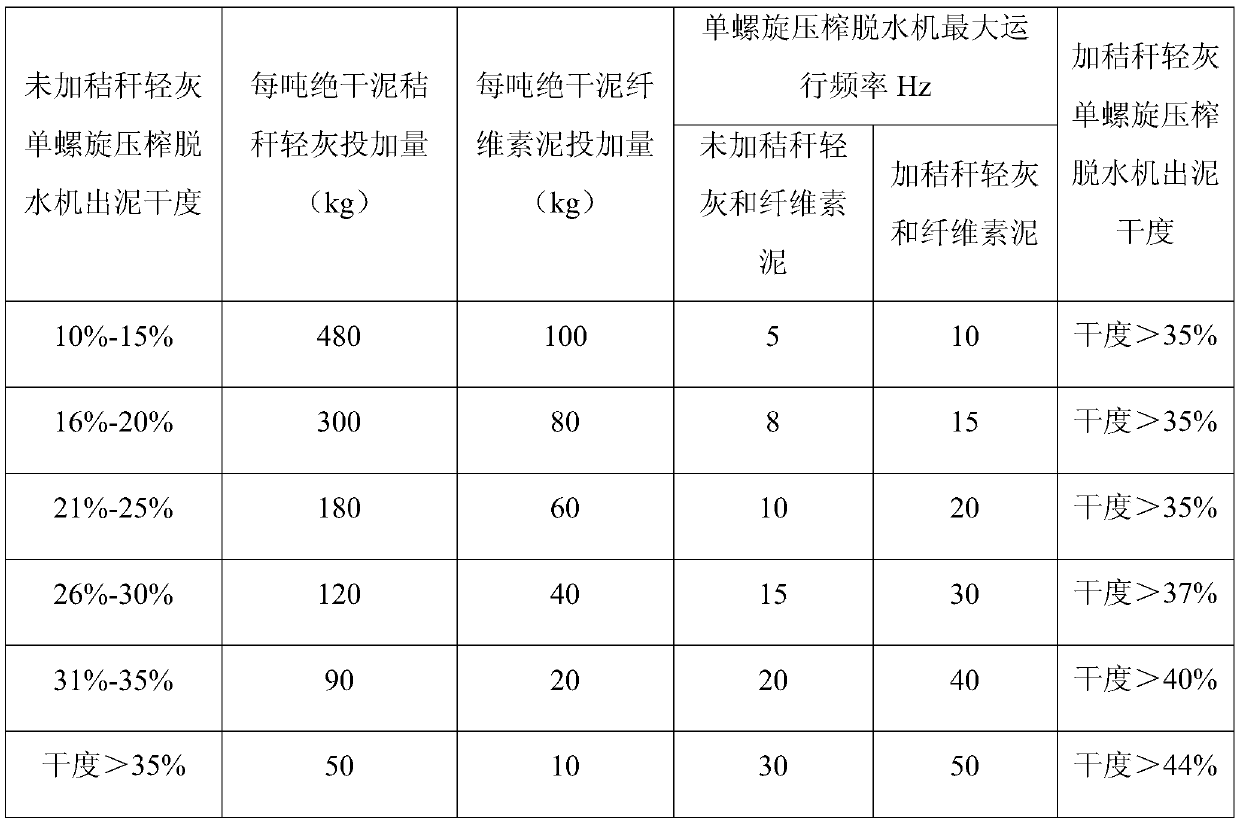

[0045] In the step (1), the addition amount of the crushed plant material is 300kg, calculated by weight per ton of absolute dry mud.

[0046] The addition amount of cellulose mud in step (1) is 50kg, by the weight of every ton of absolute dry mud.

Embodiment 2

[0048] (1) Add plant pulverized material and cellulose mud to the biomass sludge to carry out conditioning of the biomass sludge;

[0049] (2) Then add polyacrylamide cationic solution and mix to carry out biomass sludge flocculation;

[0050] (3) Finally, the double-screw pre-dehydration treatment is performed, and then the single-screw pressing dehydration treatment is obtained.

[0051] In the step (1), the addition amount of the crushed plant material is 10kg, calculated by weight per ton of absolute dry mud.

[0052] The addition amount of cellulose mud in step (1) is 10kg, by the weight of every ton of absolute dry mud.

Embodiment 3

[0054] (1) Add plant pulverized material and cellulose mud to the biomass sludge to carry out conditioning of the biomass sludge;

[0055] (2) Then add polyacrylamide cationic solution and mix to carry out biomass sludge flocculation;

[0056] (3) Finally, the double-screw pre-dehydration treatment is performed, and then the single-screw pressing dehydration treatment is obtained.

[0057] In the step (1), the addition amount of the crushed plant material is 600kg, calculated by weight per ton of absolute dry mud.

[0058] The addition amount of cellulose mud in step (1) is 100kg, by the weight of every ton of absolute dry mud.

[0059] The specific operation steps are as follows:

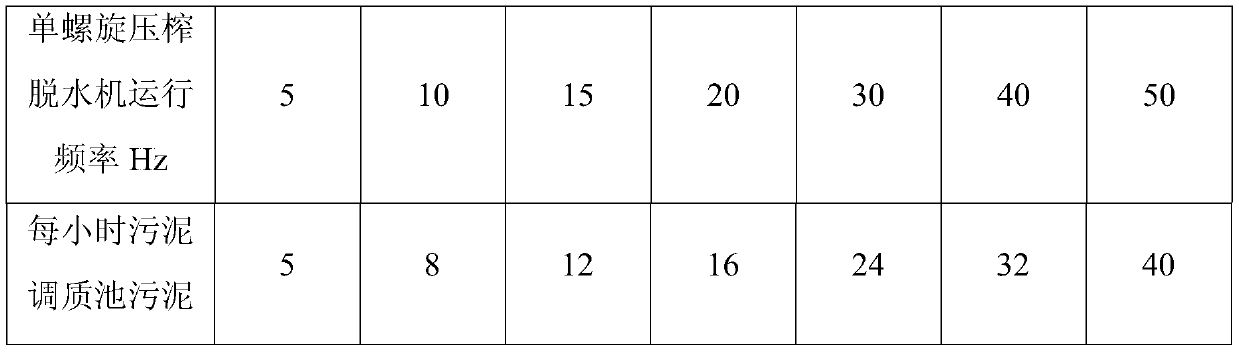

[0060] 1. Sludge tempering tank: The construction location is on the first floor of the sludge dewatering machine room. The specification is 4m long x 4m wide x 3.5m high. There is a round hole with a diameter of 1.5m on the second floor right above it. The agitator in the sludge conditioning ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com