Oversized isostatic pressing graphite and production method thereof

An ultra-large size, isostatic pressing technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the difficulties in ensuring the yield and quality of super-sized isostatic graphite materials, user troubles, and volume density Inhomogeneity problems, to achieve the effect of reduced thermal expansion coefficient, excellent isotropy, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The production specifications of this embodiment are Φ810×730mm isostatic graphite manufacturing raw materials and production methods are as follows:

[0028] A. Take raw materials according to the following weight ratio: 40 parts of pitch coke powder; 50 parts of needle coke powder; 10 parts of graphite powder; 15 parts of mesophase spheres; 45 parts of coal tar pitch; 2 parts of surfactant; modifier 1 copy;

[0029] B. Grind pitch coke powder and needle coke powder separately so that the particle size is not greater than 15 μm;

[0030] C. Grinding the graphite powder and mesophase spheres separately to make the particle size 1-10 μm;

[0031] D. Mix the powders prepared in steps B and C, and add other raw materials in step A for kneading;

[0032] E. Grinding the product obtained in step D after cooling so that the particle size is not greater than 15 μm;

[0033] F, put the powder obtained in step E into the mold for vibration molding, the density of vibration mo...

Embodiment 2

[0040] The production specifications of this embodiment are Φ810×730mm isostatic graphite manufacturing raw materials and production methods are as follows:

[0041] Take raw materials according to the following weight ratio: 35 parts of pitch coke powder; 55 parts of needle coke powder; 5 parts of graphite powder; 10 parts of mesophase spheres; 40 parts of coal tar pitch; 2 parts of surfactant; 1 part of modifier ;

[0042] The other production steps were as described in Example 1, B-J of the production steps.

[0043] The product obtained after graphitization is the final product.

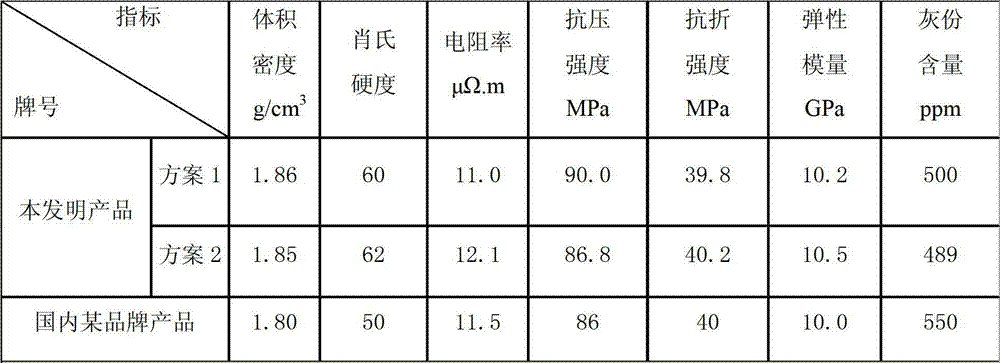

[0044] Table 1 lists the physical and chemical indicators of the isostatic graphite produced in the examples of the present invention.

[0045] Table 1: Physical and chemical indicators of isostatic graphite in the embodiments of the present invention

[0046]

[0047] The present invention adopts ultra-fine particles, unique formula and vibration molding-isostatic pressing molding method, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com