Hydrothermal synthesis method for hollow carbon nanomaterials

A technology of carbon nanomaterials and hydrothermal synthesis, applied in the direction of nanocarbon, nanotechnology, nanotechnology, etc., can solve the problems of cumbersome operation, increase production cost, limit the development and application of carbon materials, etc., achieve simple process, low cost, The effect of uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, the preparation steps of hollow carbon nanomaterials are as follows:

[0019] (1) Weigh 0.2 g glucose and 0.14 g SDBS with an electronic balance, add 30 mL H 2 Ultrasonic dispersion in O to form a uniform and transparent solution;

[0020] (2) Pour the above mixed solution into a 100 mL autoclave lined with polytetrafluoroethylene, and react at 180 °C for 6 h;

[0021] (3) After the reaction is completed, the product is taken out from the reaction kettle, and the hollow carbon nanomaterial is prepared through conventional steps such as centrifugation, washing, and drying.

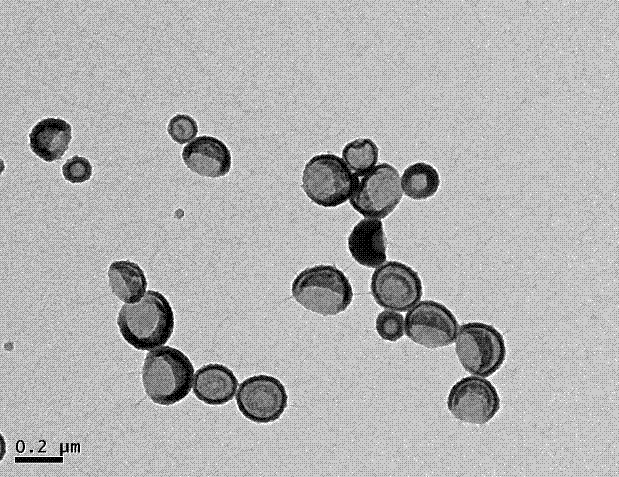

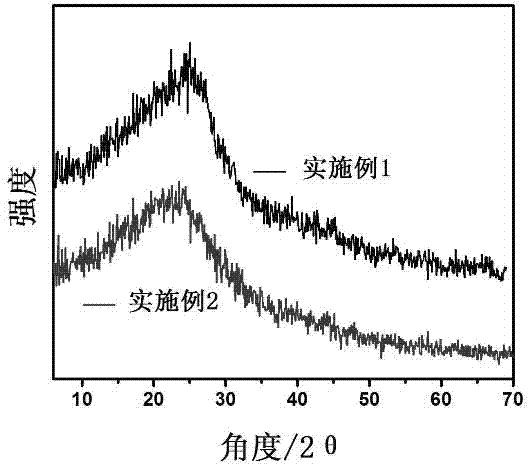

[0022] The prepared samples were characterized for their physical properties, and some of the results are shown in the attached figure 1 shown. The obtained material has a unique hollow hat-like structure with a uniform shape and a particle size of about 200 nm.

Embodiment 2

[0024] The implementation process is the same as in Example 1 except for the following differences.

[0025] (1) Weigh 0.15 g of glucose and 0.04 g of nonionic tri-block copolymer (P123) with an electronic balance, add 25 mL of H 2 Ultrasonic dispersion in O to form a uniform and transparent solution;

[0026] (2) The above mixed solution was poured into a 100 mL autoclave lined with polytetrafluoroethylene, and reacted at 170 °C for 8 h.

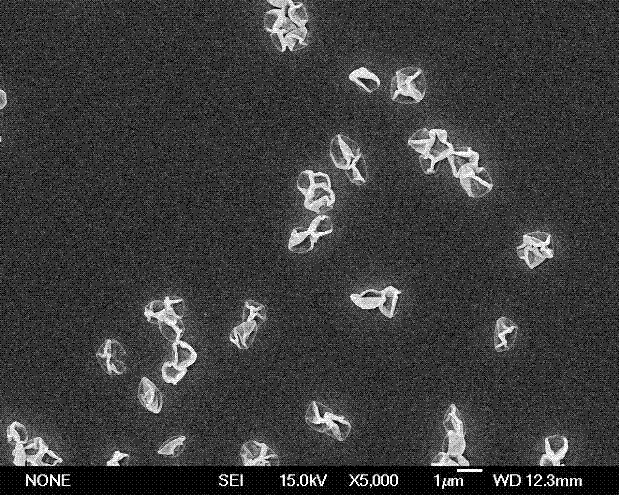

[0027] The experimental results are completely different from those in Example 1. The obtained hollow carbon nanomaterials have a particle size of about 1 μm and a shape of a deflated balloon.

Embodiment 3

[0029] The implementation process is the same as in Example 1 except for the following differences.

[0030] (1) Weigh 0.85 g sucrose and 0.35 g SDBS with an electronic balance, add 75 mL H 2 Ultrasonic dispersion in O to form a uniform and transparent solution;

[0031] The results obtained are completely different from those in Example 1, except that the hollow carbon nanomaterial obtained in this example is a complete hollow sphere structure, and its particle size is about 200-300 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com