Production method of nano-grade spherical silica powder

A production method, the technology of spherical silicon, applied in the direction of nanotechnology, chemical instruments and methods, silicon compounds, etc., can solve the problems affecting the performance of silicon material products, uneven particle size distribution, uncontrollable particle size, etc., to achieve low cost, Good thermal conductivity and short process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

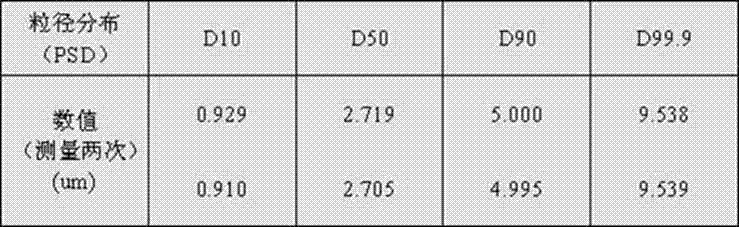

Embodiment 1

[0021] The production method of nano-scale spherical silicon powder in this embodiment is carried out in a reaction system composed of a high-temperature evaporator, a particle controller and a collector connected in sequence, including the following steps:

[0022] (1) Add silicon block raw materials with a purity ≥99.9% into the crucible in the high-temperature evaporator through the feeding port, vacuumize the reaction system, and then open the argon valve at the bottom of the high-temperature evaporator to fill the reaction system with Argon, the atmosphere inside the reaction system was made inert and the pressure inside the reaction system was 110 kPa.

[0023] (2) Turn on the plasma gun installed on the top of the high-temperature evaporator, use the generated high-frequency plasma gas as a heating source to heat the raw material of the silicon block, and heat the raw material of the silicon block to a boiling state to form silicon vapor; the gas that generates the high-...

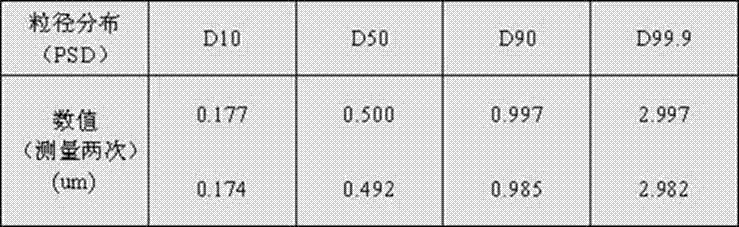

Embodiment 2

[0029] The production method of nano-scale spherical silicon powder in this embodiment is carried out in a reaction system composed of a high-temperature evaporator, a particle controller and a collector connected in sequence, including the following steps:

[0030] (1) Add silicon block raw materials with a purity ≥99.9% into the crucible in the high-temperature evaporator through the feeding port, vacuumize the reaction system, and then open the argon valve at the bottom of the high-temperature evaporator to fill the reaction system with Argon, the atmosphere inside the reaction system was made inert and the pressure inside the reaction system was 110 kPa.

[0031] (2) Turn on the plasma gun installed on the top of the high-temperature evaporator, use the generated high-frequency plasma gas as a heating source to heat the raw material of the silicon block, and heat the raw material of the silicon block to a boiling state to form silicon vapor; the gas that generates the high-...

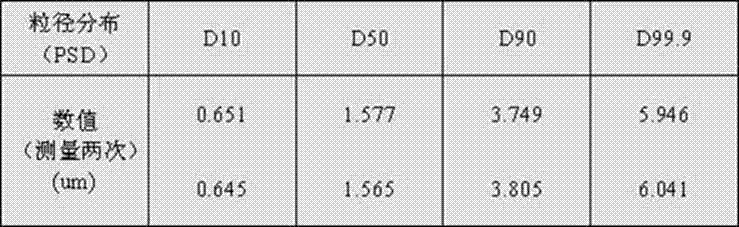

Embodiment 3

[0037] The production method of nano-scale spherical silicon powder in this embodiment is carried out in a reaction system composed of a high-temperature evaporator, a particle controller and a collector connected in sequence, including the following steps:

[0038] (1) Add silicon block raw materials with a purity ≥99.9% into the crucible in the high-temperature evaporator through the feeding port, vacuumize the reaction system, and then open the argon valve at the bottom of the high-temperature evaporator to fill the reaction system with Argon, the atmosphere inside the reaction system was made inert and the internal pressure of the reaction system was 105 kPa.

[0039] (2) Turn on the plasma gun installed on the top of the high-temperature evaporator, use the generated high-frequency plasma gas as a heating source to heat the raw material of the silicon block, and heat the raw material of the silicon block to a boiling state to form silicon vapor; the gas that generates the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com