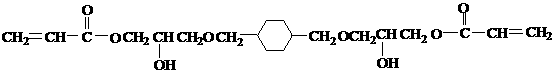

Method for preparing stereolithography rapid-prototyping photosensitive resin by adopting 1,4-cyclohexanedimethanol diglycidyl ether diacrylate as prepolymer

A technology of diglycidyl ether and cyclohexanedimethanol, which is applied in the field of preparation of stereolithography rapid prototyping photosensitive resin, achieves the effects of simple steps, good photosensitivity and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Add 3,4-epoxycyclohexylcarboxylic acid-3 , ,4 , - Epoxycyclohexyl methyl ester 1000 g, 3,3-[oxybismethylene]-bis[3-ethyl]oxetane 500 g, bisphenol A type epoxy resin (E-51) 500 grams, 1,4-cyclohexanedimethanol diglycidyl ether diacrylate 730 grams, benzoin dimethyl ether 100 grams, triarylsulfonium hexafluoroantimonate 170 grams.

[0027]2. Heat to 50°C and stir for 30 minutes to make it into a transparent light yellow uniform liquid, which is a prepared photosensitive resin. Measure its critical exposure E c 15.1mJ / cm 2 .

[0028] critical exposure E c The test method is the method reported in "Zhao Yi. Experimental Research on Properties of Photosensitive Resin in Laser Rapid Prototyping [J]. Polymer Materials Science and Engineering, 2004, 20 (1): 184-186".

[0029] 3. Utilize the SLA-3500 UV laser curing rapid prototyping equipment manufactured by 3D Systems to make some test pieces, and then post-cure these test pieces for 90 minutes in a UV box with a powe...

Embodiment 2

[0033] 1. Add 3,4-epoxycyclohexylcarboxylic acid-3 , ,4 , - Epoxycyclohexyl methyl ester 900 g, bisphenol A type epoxy resin (E-51) 600 g, 3,3-[oxybismethylene]-bis[3-ethyl]oxetane 400 grams, 1,4-cyclohexanedimethanol diglycidyl ether diacrylate 800 grams, 2-hydroxy-2-methyl-1-phenyl-1-propanone 110 grams, triarylsulfonium hexafluoroantimonic acid Salt 190 g.

[0034] 2. Heat to 40°C and stir for 30 minutes to make it into a transparent light yellow uniform liquid, which is a prepared photosensitive resin. Measure its critical exposure E c 14.9 mJ / cm 2 .

[0035] 3. Some test pieces were made by using SLA-3500 UV laser curing rapid prototyping equipment, and then these test pieces were post-cured for 90 minutes in a UV box with a power of 500 mW. Their warpage factors CF(6)=-0.01, CF(11)=-0.02 were measured.

[0036] 4. Using SLA-3500 UV laser curing rapid prototyping equipment, some test pieces were made according to ASTM D638 and ASTM D256 standards, and then post-cur...

Embodiment 3

[0038] 1. Add 3,4-epoxycyclohexylcarboxylic acid-3 , ,4 , - Epoxycyclohexyl methyl ester 500g, bisphenol A type epoxy resin (E-51) 900g, 3,3-[oxybismethylene]-bis[3-ethyl]oxetane 400 grams, 1,4-cyclohexanedimethanol diglycidyl ether diacrylate 900 grams, benzoin dimethyl ether 100 grams, triarylsulfonium hexafluoroantimonate 200 grams.

[0039] 2. Heat to 50°C and stir for 20 minutes to make it into a transparent light yellow uniform liquid, which is a prepared photosensitive resin. Measure its critical exposure E c 15.3mJ / cm 2 .

[0040] 3. Some test pieces were made by using SLA-3500 UV laser curing rapid prototyping equipment, and then these test pieces were post-cured for 90 minutes in a UV box with a power of 500 mW. Their warpage factors CF(6)=-0.01, CF(11)=-0.03 were measured.

[0041] 4. Using SLA-3500 UV laser curing rapid prototyping equipment, some test pieces were made according to ASTM D638 and ASTM D256 standards, and then post-cured for 90 minutes in a UV ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com