Method for calculating thermal fatigue failure probability of welding point of integrated circuit chip

A failure probability, integrated circuit technology, applied in computing, electrical digital data processing, special data processing applications, etc. requirements, thermal fatigue failure probability, thermal fatigue reliability calculation difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

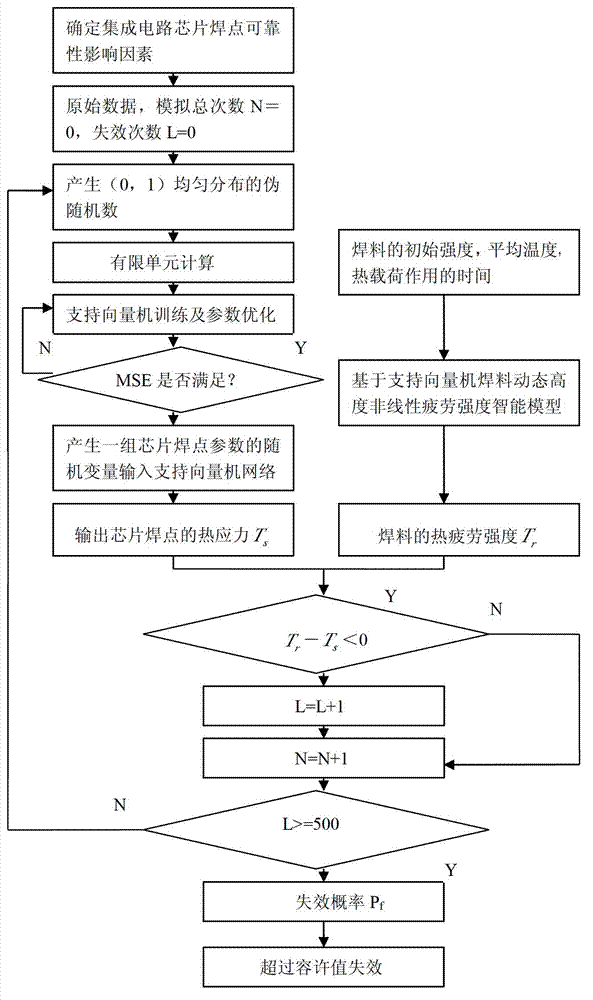

[0022] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

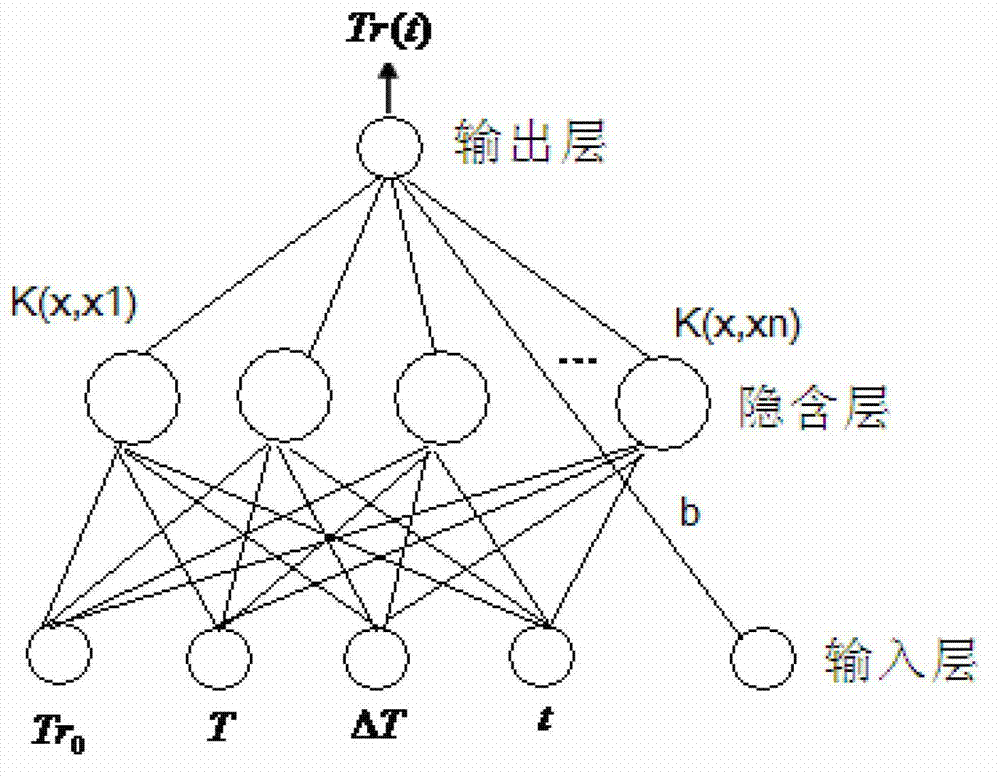

[0023] The invention provides a method for calculating the thermal fatigue failure probability of a solder joint of an integrated circuit chip, which includes the following steps:

[0024] (1) Determine the factors that affect the thermal fatigue reliability of integrated circuit chip solder joints;

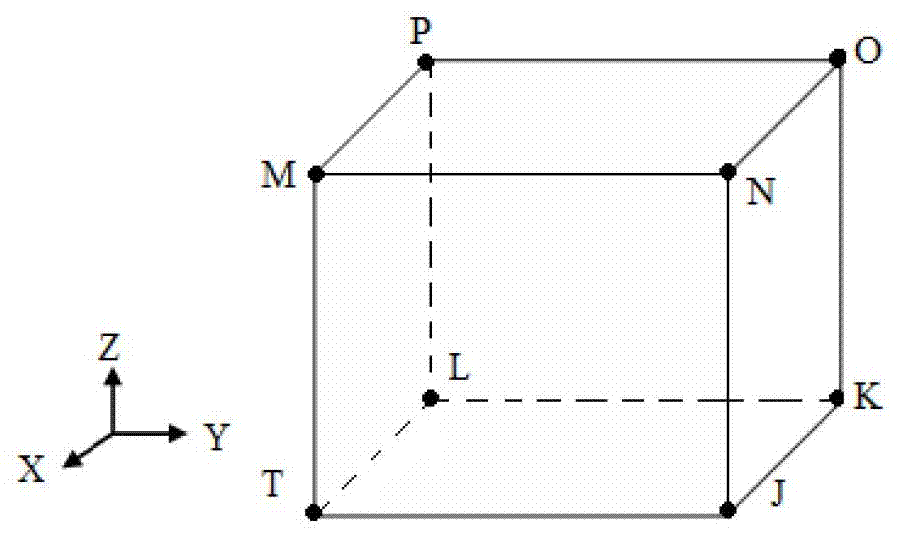

[0025] There are 16 factors that affect the thermal fatigue reliability and failure probability of integrated circuit chip solder joints. They include chip packaging and solder joint structural geometry dimensions, material characteristic parameters, and thermal load parameters. The specific parameters are as follows:

[0026] The elastic modulus of the chip body (E c ), the thermal conductivity of the chip body (TC c ), the thermal expansion coefficient of the chip body (C c ), the elastic modulus of the solder joint (E w ), the thermal conductivity of the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com