Novel lead-free sliver slurry for high-efficiency crystalline silicon solar battery as well as preparation and application thereof

A technology of solar cells and crystalline silicon, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of high cost, difficulty in realizing high-efficiency batteries and low cost, and improve conversion efficiency , Simplify the process and reduce the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

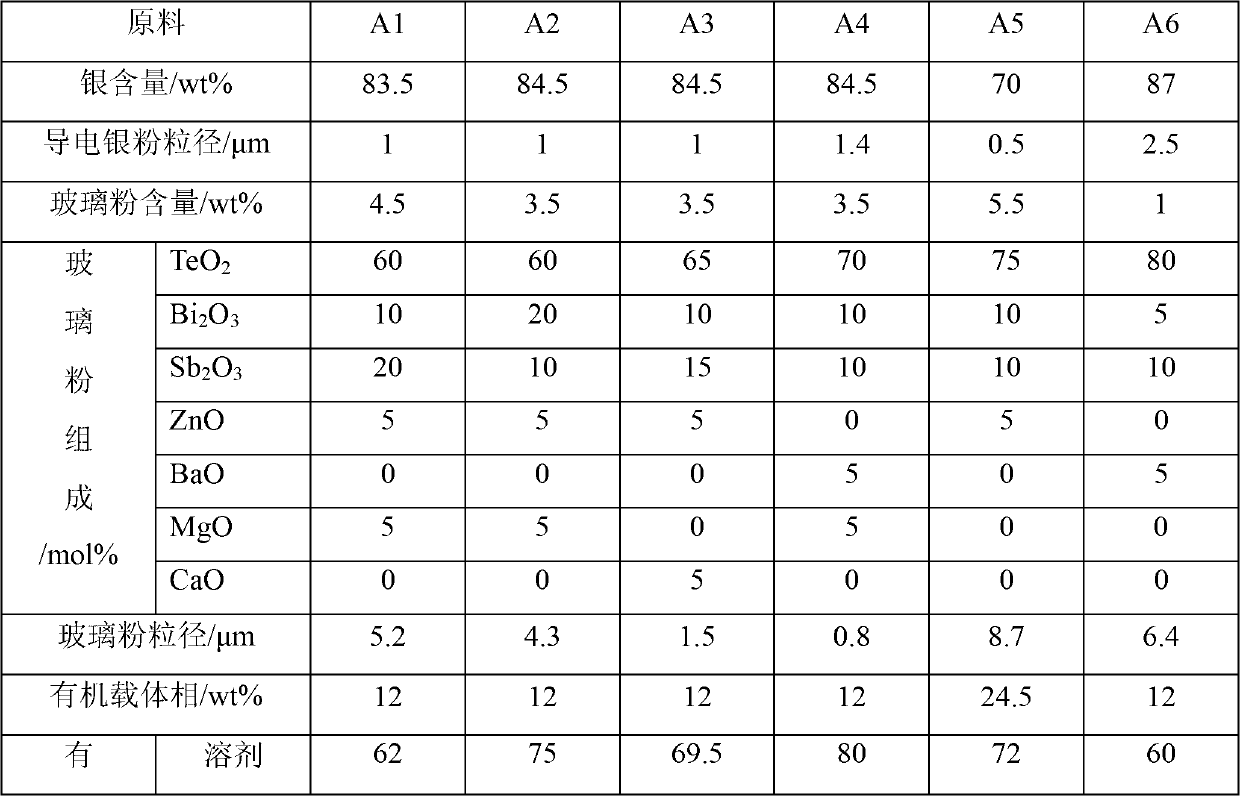

[0053] Raw materials: select raw materials according to Table 1. Examples 1-6 are respectively added with TeO with different compositions and particle sizes listed in Table 1 2 -Bi 2 O 3 -Sb 2 O 3 -MO (M=Zn, Mg, Ba, Ca) glass powder

[0054] aTeO 2 -b(Bi 2 O 3 ,Sb 2 O 3 )-cMO glass preparation method:

[0055] First, mix and grind the raw materials in accordance with Table 1 thoroughly, then add the mixed raw materials into the corundum crucible, heat and melt at 900~1300℃ for 1-5h, then ball mill after water quenching, and grind to a particle size of 0.5-10μ. , Dry to obtain the required glass powder.

[0056] Slurry preparation method:

[0057] Weigh the conductive silver powder and lead-free glass powder according to the proportion in Table 1, mix them thoroughly to obtain the mixed powder, put the mixed powder in the organic carrier phase according to the proportion, stir and pre-disperse, and roll it in a three-roller until the scraper fineness is less than 14 μm to obtain the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com