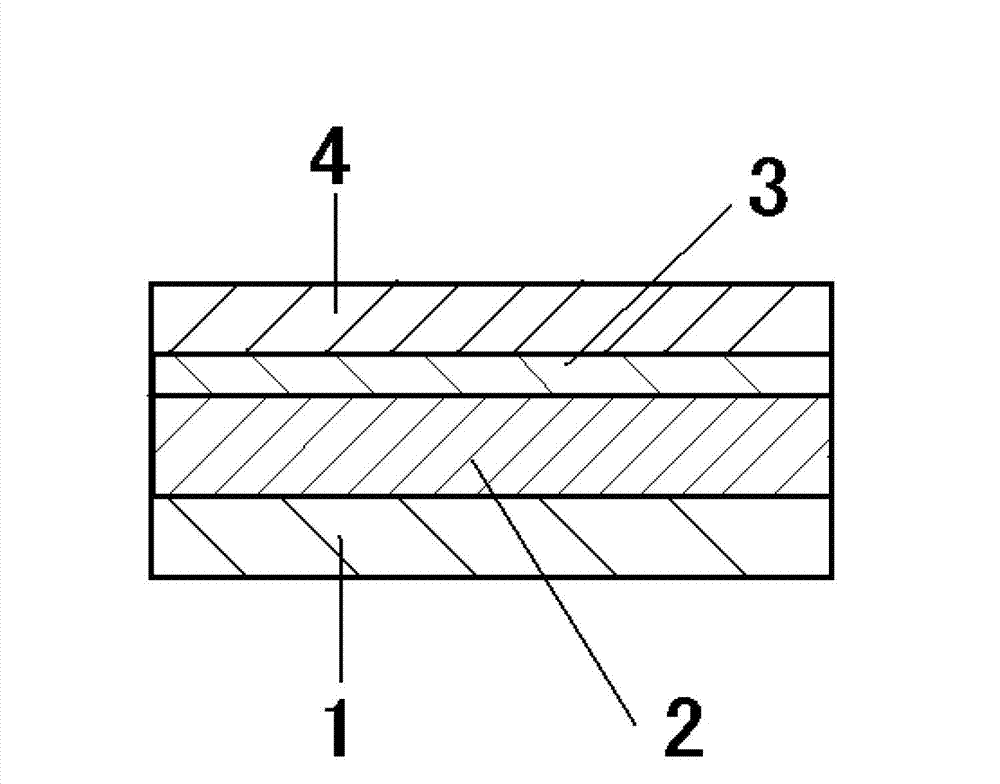

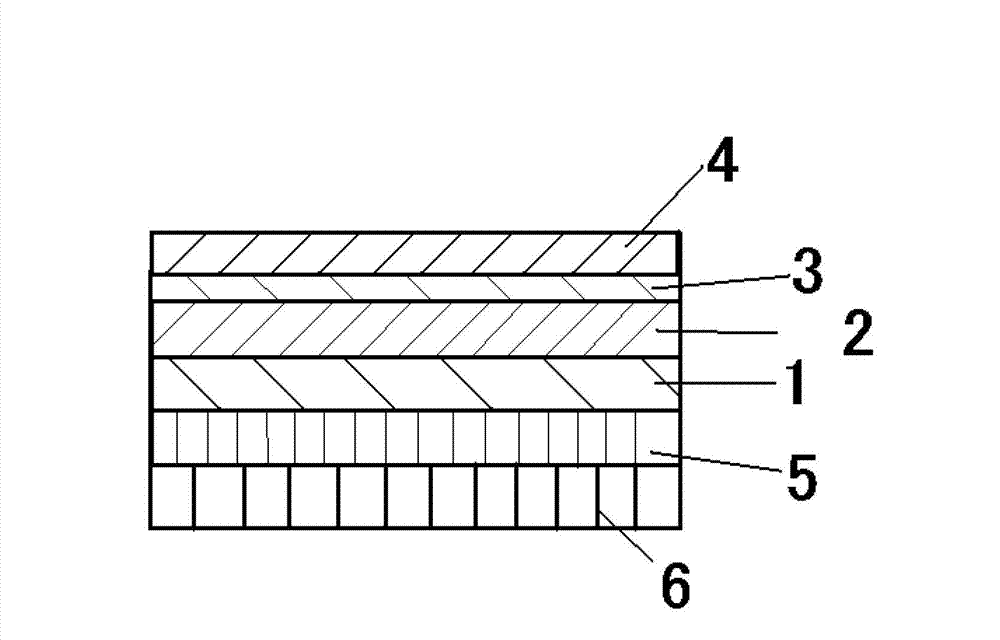

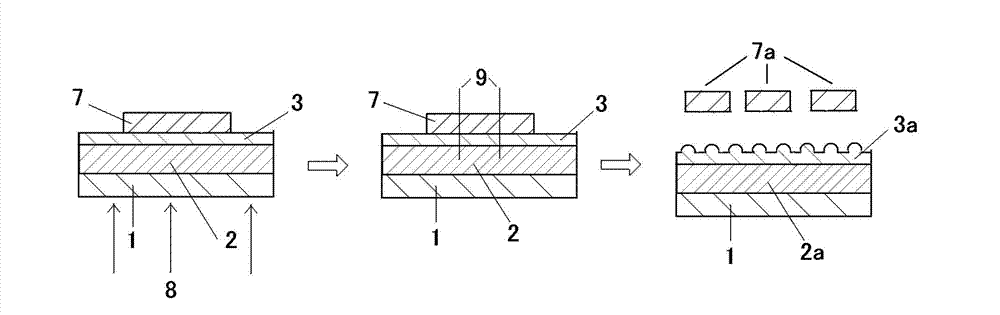

Heat-peelable adhesive sheet

A technology of adhesive sheet and peeling type, which is applied in the direction of adhesive heating bonding method, heat-activated film/sheet, polymer adhesive additive, etc., which can solve the problem of indistinguishable and peeling type Reduce the light transmittance of the adhesive sheet, change the color of the heat-peelable adhesive layer, etc., to achieve reliable processing, reduce impact, and prevent short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0131] The heat-peelable pressure-sensitive adhesive sheet of Example 1 was produced in the following procedure.

[0132] First, prepare 100 parts by weight of a copolymer-based pressure-sensitive adhesive containing 2-ethylhexyl acrylate-ethyl acrylate-methyl methacrylate (polymerized in proportions of 30, 70, and 5 parts by weight in sequence) (compounding A toluene solution of 1 part by weight of an isocyanate-based crosslinking agent) was applied to a polyester film with a thickness of 100 μm as a base material so that the thickness after drying was about 15 μm, to obtain a rubbery organic elastic layer.

[0133] Next, prepare Matsumoto Microsphere mixed with 100 parts by weight of 2-ethylhexyl acrylate-ethyl acrylate-methyl methacrylate copolymer-based pressure-sensitive adhesive (mixed with 2 parts by weight of isocyanate-based crosslinking agent) - F-501D (trade name, manufactured by Matsumoto Oil & Fat Pharmaceutical Co., Ltd.) 30 parts by weight, and a toluene solutio...

Embodiment 2)

[0136] The heat-peelable adhesive sheet of Example 2 was obtained like Example 1 except having mix|blended 0.5 weight part of metal element containing solid pigments instead of 0.01 weight part.

Embodiment 3)

[0138] The heat-peelable adhesive sheet of Example 3 was obtained like Example 1 except having mix|blended 0.8 weight part of metal element containing solid pigments instead of 0.01 weight part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com