Spinneret for spinning threads, spinning device for spinning threads and method for spinning threads

A spinning device and spinneret technology, applied in spinneret assemblies, stretch spinning, textiles, etc., can solve the problems of high energy consumption, increase process equipment consumption, etc., and achieve the effect of increasing throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

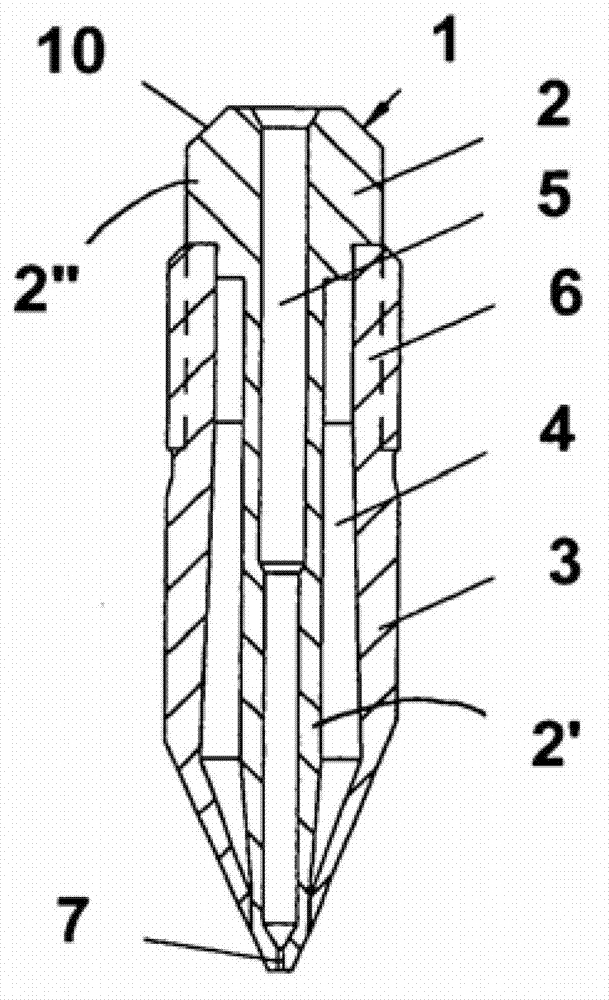

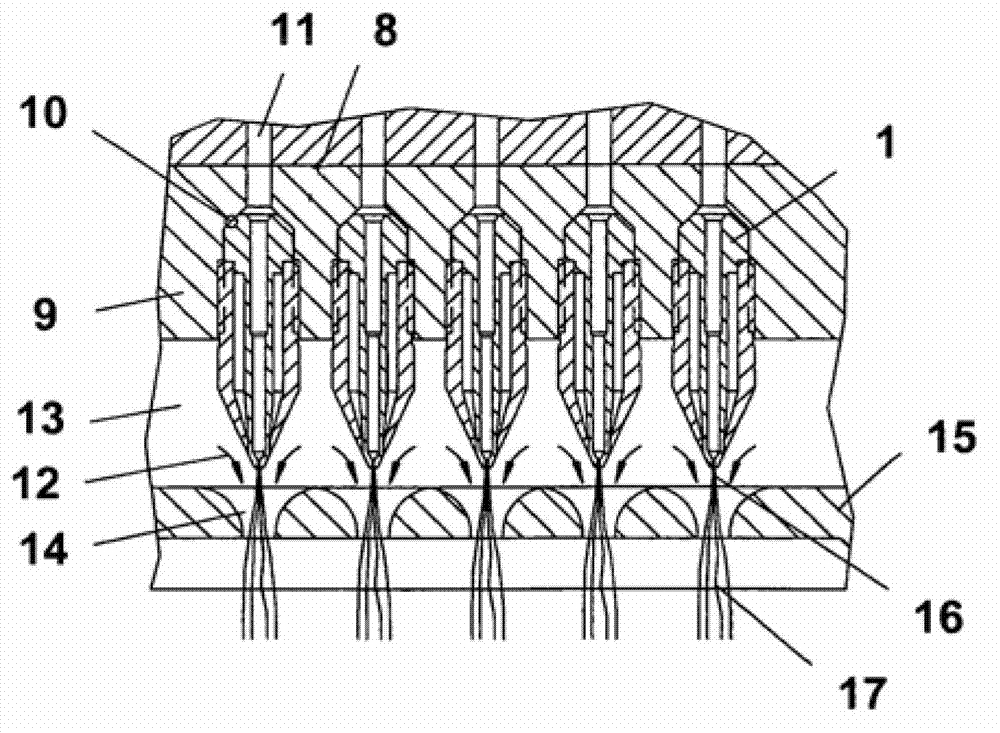

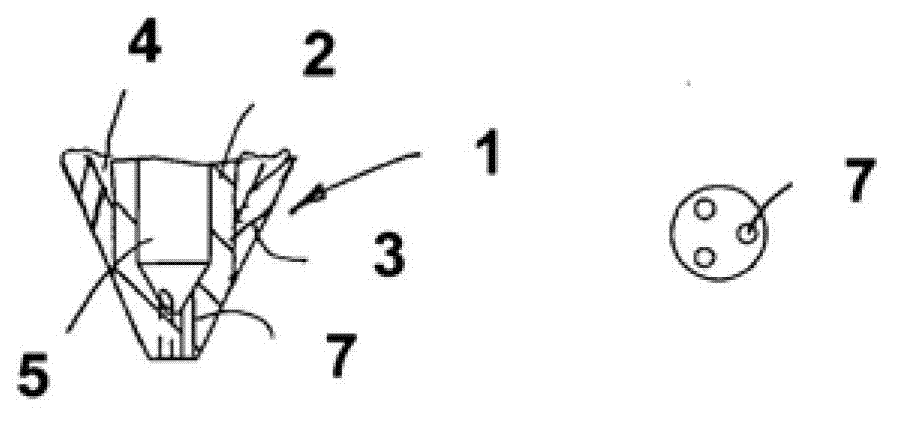

[0041] exist figure 2 An arrangement of a plurality of spinnerets 1 in the form of spinning nozzles, using image 3 A configuration with three openings with a diameter of 0.25 mm. For each hole or hole, the throughput of polypropylene is 1.5g / min, and the melt flow index MFI (melt flow index, also known as MFR, melt flow rate) is 28 and 1,200, which are based on ISO 1133 Measured on a standardized device, expressing how many grams of heated thermoplastic polymer are extruded through a spinneret in 10 minutes under the action of a fixed force, here for polypropylene, at 230 ° C and 2.16 kg, the average filament diameter after splitting was obtained, measured in a microscope from 20 individual filaments: at 1.5 g / min and MFI 28, provided 1 capillary with a diameter of 0.25 mm, the average The filament diameter is 1.1 μm with a minimum diameter of 0.8 μm, and at MFI 1,200, the average filament diameter is 0.95 μm with a minimum diameter of 0.4 μm. In the case of three capilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com