Application of citronella slag in cigarette manufacturing and preparation method of tobacco leaves reconstituted from citronella

A technology for reconstituting tobacco leaves and citronella, which is applied in the field of application and preparation of citronella reconstituted tobacco leaves, can solve the problems of pollution, no reuse of citronella slag, low utilization rate, etc. The effect of the raw material demand problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Preparation of reconstituted tobacco leaves made from citronella residue and wood pulp fiber

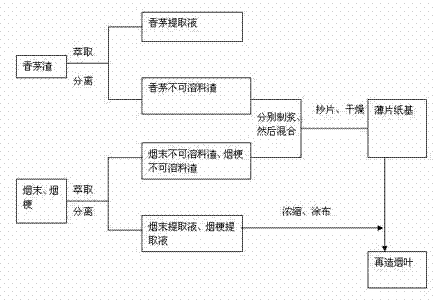

[0039] The preparation method flow chart of the reconstituted tobacco leaf described in this embodiment is as attached figure 1 shown.

[0040] The citronella residue comes from the residue after citronella extraction in the flavor and fragrance factory; the tobacco powder, tobacco stem and wood pulp fiber are directly purchased by the chip factory, and are conventional commercially available tobacco powder, tobacco stem and wood pulp fiber. In this example, 100kg of citronella residue was added to 600kg of water and extracted with conventional equipment at 80°C for 30 minutes, and 530kg of citronella extract and 170kg of citronella insoluble residue (non-dried) were obtained through solid-liquid separation;

[0041] Take 1200kg of tobacco powder as raw material, add 6000kg of water, extract with conventional equipment at 80°C for 30 minutes, and obtain 5160kg ...

Embodiment 2

[0048] Example 2 Preparation of reconstituted tobacco leaves from citronella residue

[0049] The citronella residue comes from the residue after citronella extraction in the flavor and fragrance factory; the tobacco powder, tobacco stem and wood pulp fiber are directly purchased by the tobacco sheet factory, and are conventional commercially available tobacco powder, tobacco stem and wood pulp fiber. In this example, add 1800 kg of water to 300 kg of citronella residue and extract at 80 ° C for 30 minutes using conventional extraction equipment in tobacco companies. After solid-liquid separation, 1590 kg of citronella extract and 510 kg of citronella insoluble residue (non-drying) are obtained. ;

[0050] Take 900kg of tobacco powder as a raw material, add 4500kg of water, extract with conventional equipment at 80°C for 30 minutes, and obtain 3870kg of tobacco powder extract and 1530kg of tobacco powder insoluble slag (non-drying) through solid-liquid separation;

[0051] ...

Embodiment 3

[0057] Example 3 Preparation of reconstituted tobacco leaves from citronella residue

[0058] The citronella residue comes from the residue after citronella extraction in the flavor and fragrance factory; the tobacco powder, tobacco stem and wood pulp fiber are directly purchased by the chip factory, and are conventional commercially available tobacco powder, tobacco stem and wood pulp fiber. In this example, 300kg of citronella residue was added to 1800kg of water and extracted with conventional equipment at 80°C for 30 minutes, and 1590kg of citronella extract and 510kg of citronella insoluble residue (non-dried) were obtained through solid-liquid separation;

[0059] Take 600kg of tobacco powder as a raw material, add 3000kg of water, extract with conventional equipment at 80°C for 30 minutes, and obtain 2580kg of tobacco powder extract and 1020kg of tobacco powder insoluble slag (non-drying) through solid-liquid separation;

[0060] Take 100kg of tobacco stems as a raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com