Uncoated zero-polar-distance ion exchange membrane and preparation method thereof

A technology of ion-exchange membrane and zero pole distance, which is applied in the direction of chemical instruments and methods, membrane technology, organic diaphragm, etc., can solve the problems of performance degradation, coating peeling, etc., and achieve the goal of reducing cell voltage, prolonging service life, and reducing accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

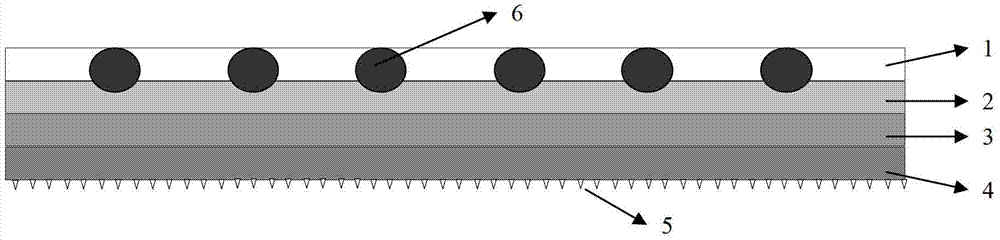

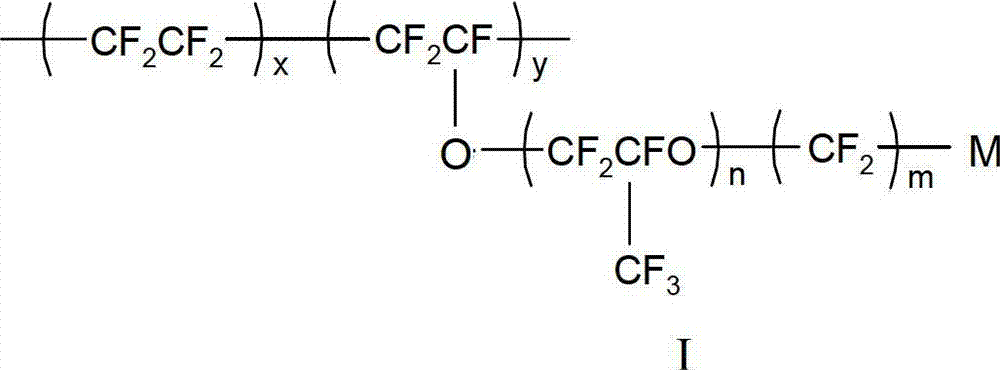

[0053] Example 1: Preparation of an uncoated zero-pole-distance sub-exchange membrane with a four-layer membrane structure

[0054] The uncoated zero-pole distance sub-exchange membrane with four-layer membrane structure is composed of perfluorinated ion-exchange resin base membrane and reinforcing material. The perfluorinated ion-exchange resin base membrane has a four-layer membrane structure through multi-layer co-extrusion prepared in the same way; among them, the first film from top to bottom is perfluorosulfonic acid resin with IEC=1.4mmol / g (M in formula I is -SO 2 F, x=2.9, n=1, m=3); the second film is perfluorocarboxylic acid resin with IEC=0.95mmol / g (M in formula I is -COOCH 3 , x=6.3, n=1, m=3); the third film is a perfluorosulfonic acid carboxylic acid blend resin with IEC=1.0mmol / g (x=4.5, n=1, m=3, blended The mass ratio is 1:1); the fourth film is a perfluorosulfonic acid resin with IEC=1.33mmol / g (M in formula I is -SO 2 F, x=3.6, n=1, m=4); the thickness i...

Embodiment 2

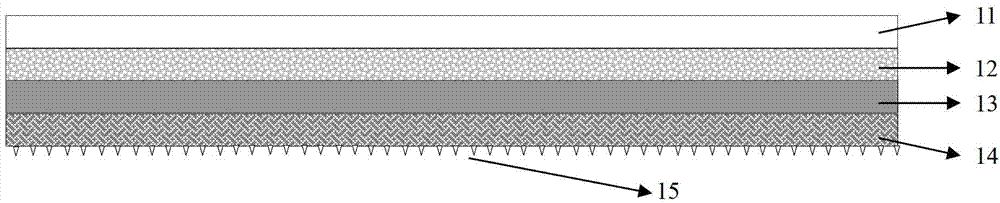

[0059] Example 2: Preparation of an uncoated zero-pole distance sub-exchange membrane with a five-layer membrane structure

[0060] (1) IEC=1.15mmol / g perfluorosulfonic acid resin (1 layer of raw materials) (x=5.1, n=0, m=5), IEC=0.99mmol / g perfluorocarboxylic acid resin (2 layers Raw material) (x=7.3, n=1, m=2), IEC=1.0mmol / g perfluorosulfonic acid carboxylic acid blend resin (3-layer raw material) (x=6.5, n=1, m=4) , IEC=1.1mmol / g perfluorosulfonic acid resin (4 layers of raw materials) (x=5.3, n=1, m=5) and IEC=1.28mmol / g perfluorosulfonic acid resin (5 layers of raw materials) ( x=4.0, n=1, m=3) were compounded into films by co-extrusion casting, in which the thickness of 1 layer was 15 microns, the thickness of 2 layers was 8 microns, the thickness of 3 layers was 70 microns, and the thickness of 4 layers was 50 microns, 5-layer thickness of 15 microns, and a total thickness of 158 microns; PFA mesh cloth is introduced during the forming process, and rolled into the film...

Embodiment 3

[0063] Example 3: Preparation of an uncoated zero-pole distance sub-exchange membrane with a six-layer membrane structure

[0064] (1) IEC=1.2mmol / g perfluorosulfonic acid resin (1 layer raw material) (x=4.9, n=0, m=3), IEC=1.05mmol / g perfluorosulfonic acid resin (2 layers Raw material) (x=6.0, n=1, m=4), IEC=0.92mmol / g perfluorocarboxylic acid resin (3-layer raw material) (x=7.3, n=1, m=3), IEC=1.0 mmol / g perfluorosulfonic acid carboxylic acid blend resin (4 layers of raw material) (x=5.1, n=0, m=5), IEC=1.05mmol / g perfluorosulfonic acid carboxylic acid blend resin (5 layer raw material) (x=4.4, n=1, m=4) and IEC=1.3mmol / g perfluorosulfonic acid resin (6 layer raw material) (x=3.5, n=0, m=3) by co-extrusion The composite film is formed by casting, wherein the thickness of 1 layer is 10 microns, the thickness of 2 layers is 20 microns, the thickness of 3 layers is 50 microns, the thickness of 4 layers is 90 microns, the thickness of 5 layers is 30 microns, and the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cation exchange capacity (mol) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com