Preparation method and application of dye-sensitized heteropolyacid catalyst with visible light photocatalytic activity

A technology of photocatalytic activity and dye sensitization, applied in the field of photocatalysts, can solve the problems of limited reuse, visible light not being utilized by heteropoly acids, etc., and achieve the effect of wide application prospects and high catalytic degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

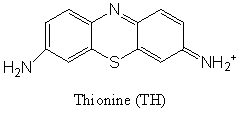

[0011] Example 1: Dye-sensitized H 3 PW 12 o 40 Preparation of photocatalyst

[0012] According to Thiogen and H 3 PW 12 o 40 The molar ratio of the substance is 3:1, slowly add the 0.1mM / ml thionium aqueous solution to the 0.1mM / ml H 3 PW 12 o 40 In the aqueous solution, the mixed solution was stirred and reacted at room temperature for 5 hours, and a dark purple precipitate was obtained. After centrifugation, the precipitate was washed with distilled water until the clear liquid was colorless, and dried in an oven at 50°C for 5 hours to obtain dye-sensitized H 3 PW 12 o 40 catalyst of light.

[0013] Dye-sensitized H 3 PW 12 o 40 The solid-state ultraviolet-visible diffuse reflectance spectrum characterization of the catalyst was carried out on a Lambda-900 ultraviolet-visible spectrometer produced by PerkinElmer, USA. The ultraviolet-visible diffuse reflectance spectrum shows that the dye-sensitized catalyst has a large absorption in the visible region of 400...

Embodiment 2

[0014] Example 2: Dye-sensitized H 3 PW 12 o 40 Photocatalytic degradation of methyl orange (MO) under visible light

[0015] Take 5 ml MO (10 mg / L) into a quartz test tube, and then add 30 mg of dye-sensitized H 3 PW 12 o 40 The catalyst is illuminated with a CHF-XM35-500W xenon lamp, and a filter is added on the surface of the test tube to filter out light waves below 420nm. During the illumination process, it is cooled with cooling water and the temperature is kept at 20°C. The catalyst was irradiated under xenon lamp for a certain period of time, and the catalyst was separated by centrifugation, and the methyl orange solution was measured with a Lambda-900 UV-visible spectrometer produced by PE Company to measure the change of the methyl orange UV-visible absorption spectrum of the dye during the illumination process, and the reaction was measured. The absorption value of the liquid at the wavelength of maximum absorption Carry out blank and control experiments at t...

Embodiment 3

[0021] Example 3: Dye Sensitization H 3 PW 12 o 40 Photocatalytic degradation of rose bengal (RhB) under visible light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com