Assembling method for liquid storage device and compressor

An assembly method and compressor technology, applied in the field of compressors, can solve problems such as high cost, complicated assembly process, and easy gas leakage, and achieve the effects of simple structure, reduced welding material consumption, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

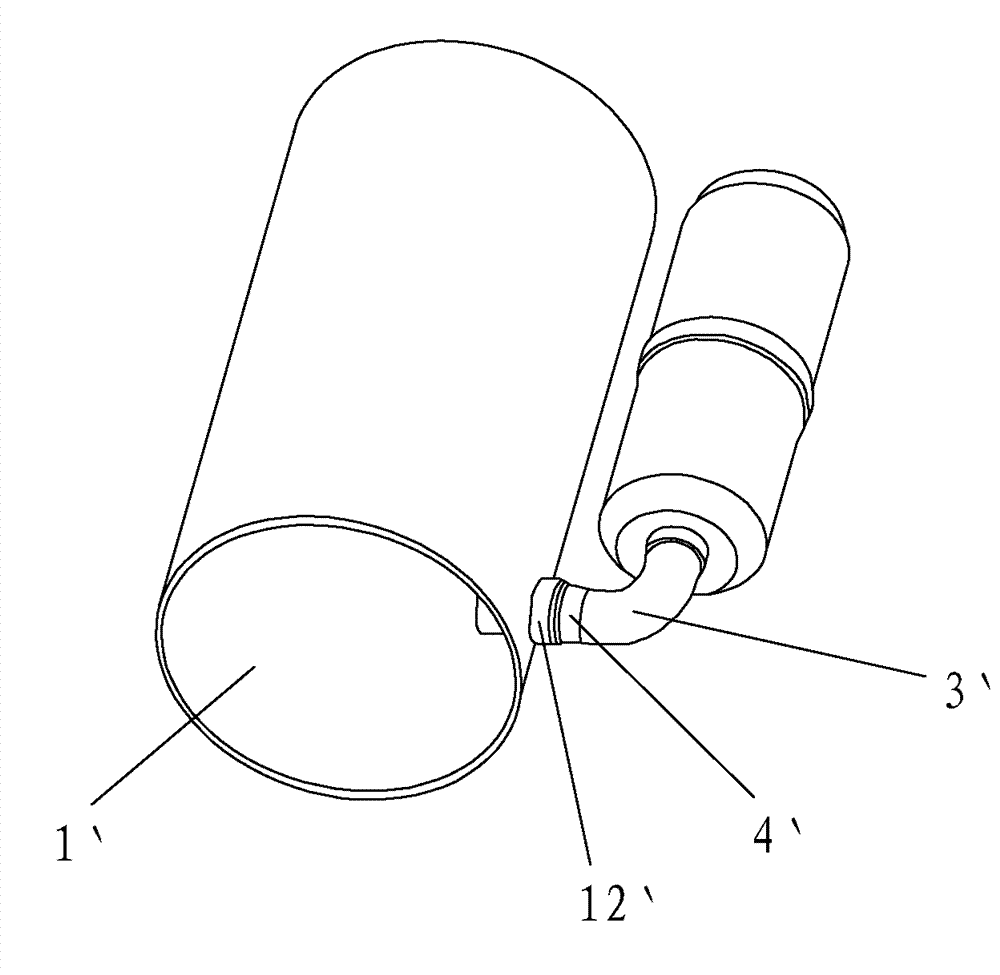

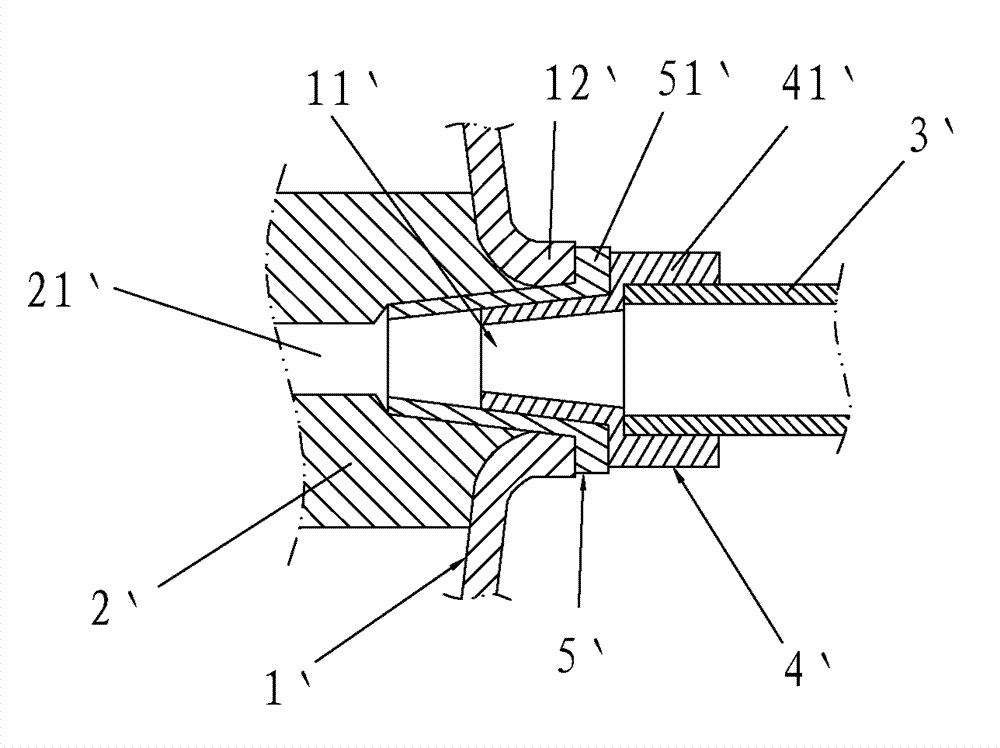

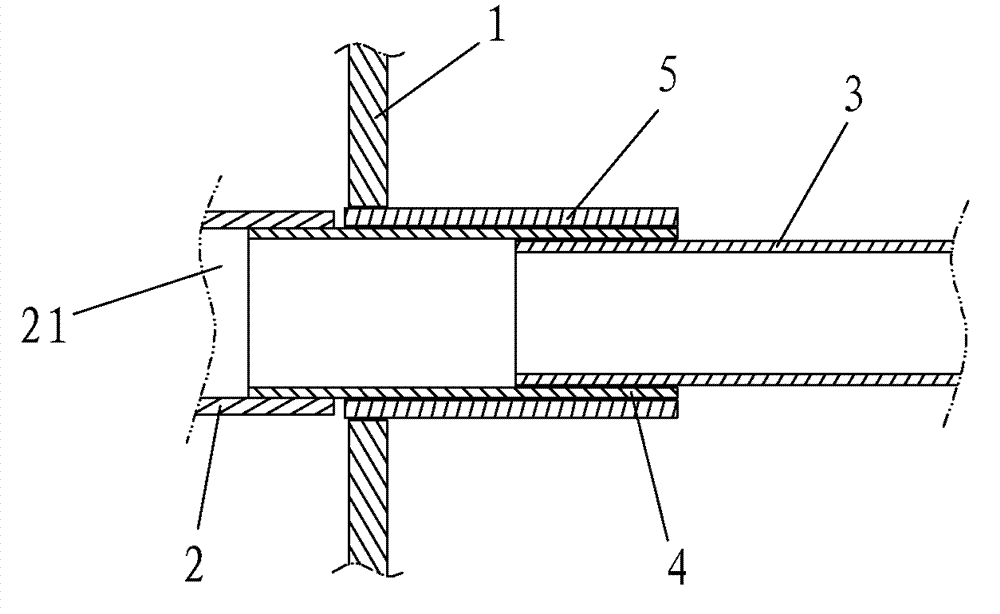

[0036] Such as Figure 4 , Figure 5 As shown, the method for assembling the liquid accumulator and the compressor of this embodiment includes the following steps:

[0037] a. A through hole 11 is provided on the side of the shell 1 of the compressor. The edge of the through hole 11 is provided with a flanging 12. The flanging 12 can be formed by stamping. The angle between the flanging 12 and the intake pipe 3 is 0-90° °, the included angle being 0-90° means that the shape of the flanging 12 is a trumpet shape that flares outwards, and the flanging 12 of the trumpet shape is convenient for the air intake pipe 3 to be inserted into the through hole 11, and is also convenient for aligning the flanging 12 with the air intake pipe. 3 welding, the diameter of the through hole 11 is greater than the outer diameter of the intake pipe 3, and the housing 1 is made of steel;

[0038] b. Set the cylinder 2 in the housing 1, the air inlet 21 of the cylinder 2 is in the same direction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com