Composite board, metamaterial and preparation methods

A composite board and metamaterial technology, applied in chemical instruments and methods, special decorative structures, decorative art, etc., can solve the problems of pollution, high cost of electroplating copper plating, etc., and achieve the effects of cost reduction, low cost, and small dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

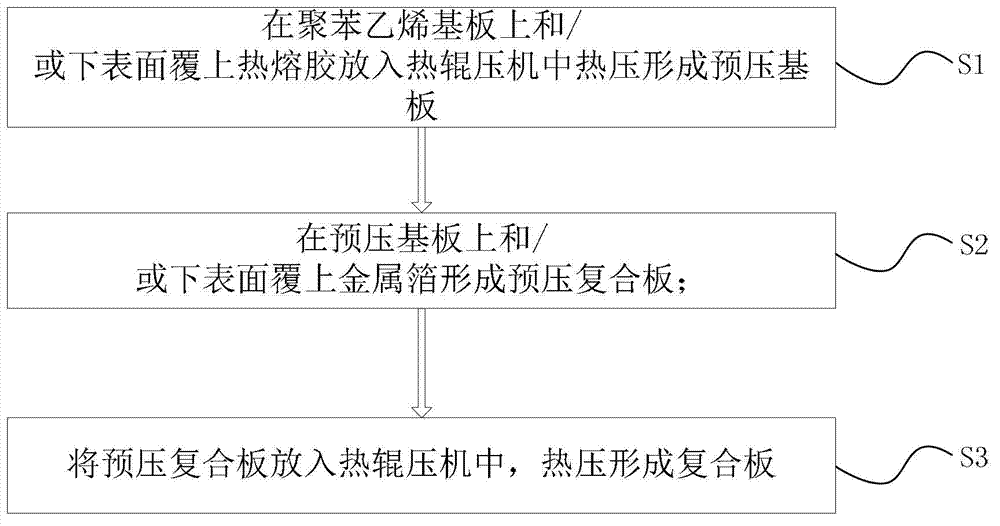

[0037] A preparation method for a composite board, comprising the following steps, such as figure 1 shown.

[0038] S1. Cover the polystyrene substrate with hot melt adhesive and / or the lower surface, put it into a hot roller press and heat press to form a pre-pressed substrate; the hot melt adhesive is preferably TPU hot melt adhesive, PU hot melt adhesive, PO hot melt Glue or EVA hot melt glue. Preferably, the hot pressing temperature in step S1 is 80-280°C. Preferably, the rolling pressure in step S1 is 2 ~ 30kg / cm 2 . Preferably, the rolling speed in step S1 is 2-30 min / m.

[0039] S2. Coating metal foil on the pre-pressed substrate and / or the lower surface to form a pre-pressed composite board; the metal foil is copper foil, silver foil or aluminum foil, and of course other available metal foils are also available. Preferably, the metal foil has a thickness of 0.005-0.15 mm.

[0040] S3. Put the pre-pressed composite board into a hot roller press, and heat-press to ...

Embodiment 1

[0044] S1. Cover the polystyrene substrate and / or the lower surface with EVA hot melt adhesive and put it into a hot roller press to form a pre-pressed substrate; the hot pressing temperature is 121°C and the rolling pressure is 20kg / cm 2 , The rolling speed is 1.1m / min;

[0045] S2. Cover the upper and / or lower surface of the pre-pressed substrate with copper foil with a thickness of 0.02 mm to form a pre-pressed composite board;

[0046] S3. Put the pre-pressed composite board into a hot roller press and heat press it to form a supermaterial composite board. The hot pressing temperature is 121°C and the rolling pressure is 20kg / cm 2 , The rolling speed is 1.1m / min.

[0047] The composite board obtained in Example 1 was tested by a peel strength tester (IPC-TM-650), and the peel strength was 1.8Kgf / cm.

Embodiment 2

[0049] S1. Cover the polystyrene substrate and / or the lower surface with EVA hot melt adhesive and put it into a hot roller press to form a pre-pressed substrate; the hot pressing temperature is 100°C and the rolling pressure is 15kg / cm 2 , The rolling speed is 2m / min;

[0050]S2. Cover the upper and / or lower surface of the pre-pressed substrate with copper foil with a thickness of 0.02 mm to form a pre-pressed composite board;

[0051] S3. Put the pre-pressed composite board into a hot roller press and heat press to form a supermaterial composite board. The hot-pressing temperature is 140°C and the rolling pressure is 20kg / cm 2 , The rolling speed is 3m / min.

[0052] The composite board obtained in Example 2 was tested by a peel strength tester (IPC-TM-650), and the peel strength was 1.7Kgf / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com