Treatment method of organic waste water with high calcium and high pH value

A technology for organic wastewater and treatment methods, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. The effect of simplifying management and reducing the cost of acid addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

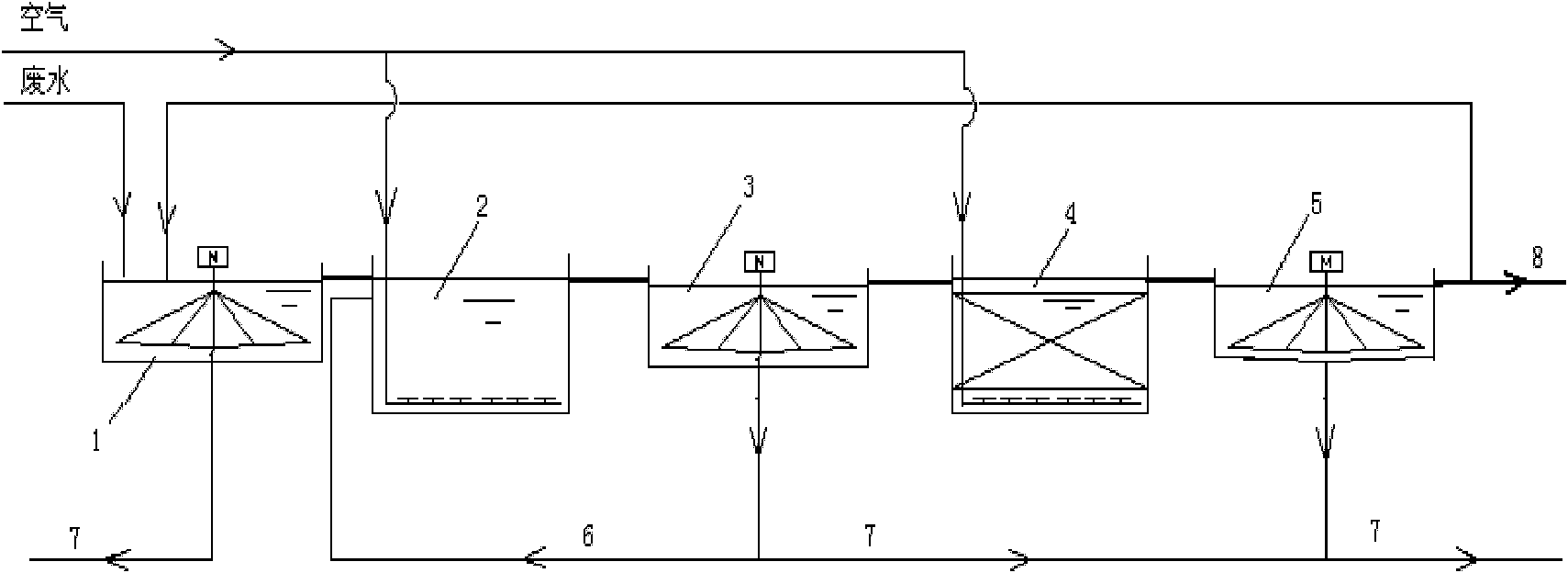

Image

Examples

Embodiment 1

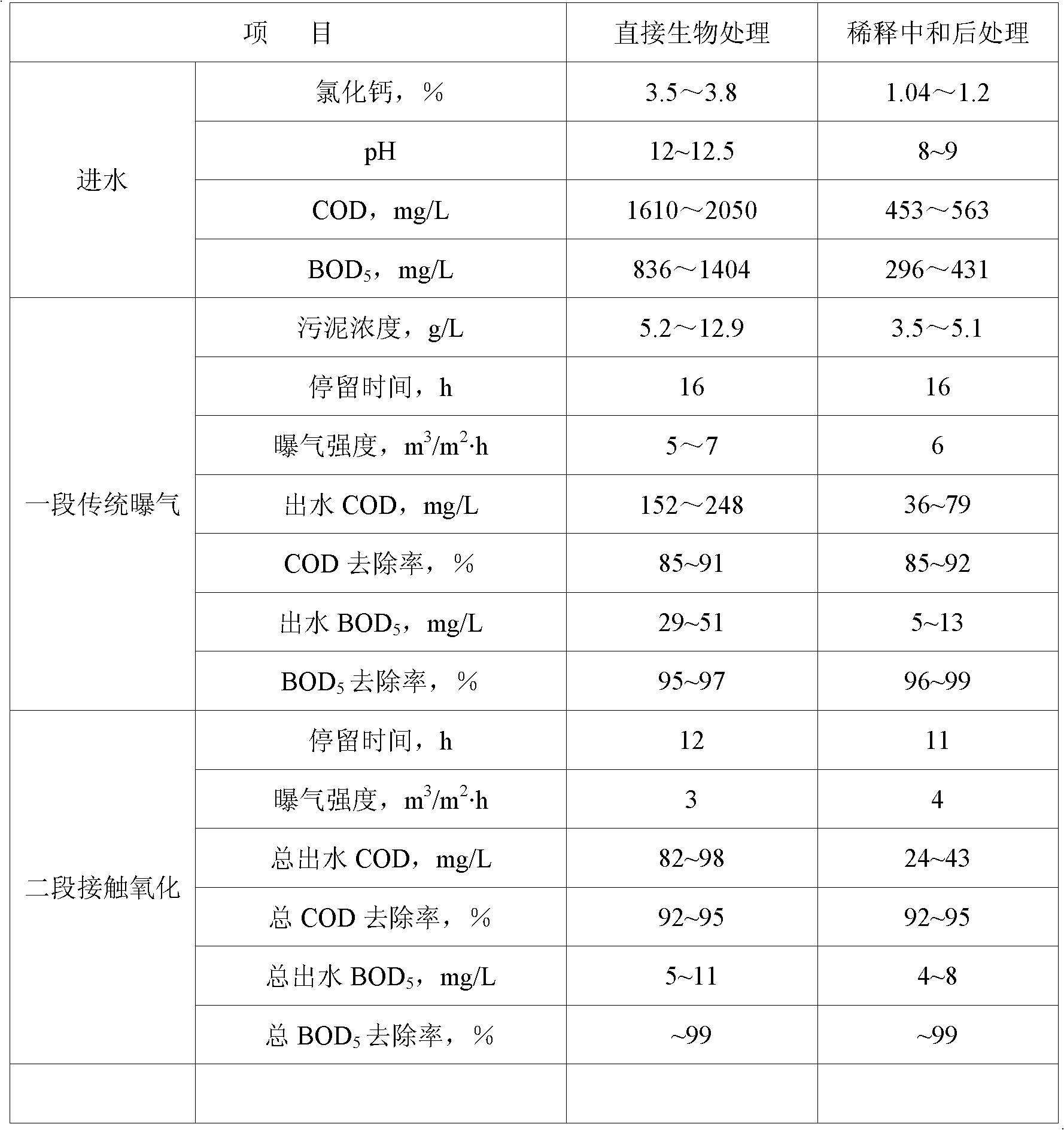

[0023] 1. See attached table 1 for the comparison between direct biological treatment of wastewater with high calcium chloride content and high pH and dilution with water and neutralization with hydrochloric acid.

[0024] Schedule 1

[0025]

[0026] 2. The raw wastewater and the diluted and neutralized wastewater enter an aeration tank respectively, and after 16 hours of biological treatment, most of the organic matter is removed, and the COD and BOD after direct biological treatment 5 The average removal rate reaches 88% and 96% respectively; COD and BOD after biological treatment after dilution and neutralization 5 The average removal rates reached 89% and 98%, respectively.

[0027] 3. After the first stage of biological treatment, the effluent enters the second stage of contact oxidation to further remove organic matter. After the second stage of biological treatment, the total effluent COD and BOD after direct biological treatment 5 The removal rate reaches 94% an...

Embodiment 2

[0029] 1. See Attached Table 2 for the high calcium chloride content and high pH wastewater quality of a propylene oxide production plant.

[0030] Schedule 2

[0031] Analysis Project

Raw wastewater

A traditional aeration treatment

Two stage contact oxidation treatment

pH

11.4

8.1

7.1

Ca(OH) 2 ,mg / L

610

/

/

CaCl 2 ,%

2.6

2.5

2.5

COD, mg / L

1030

308

55

COD removal rate, %

70

95

BOD 5 ,mg / L

577

28

9

BOD 5 , removal rate, %

95

98

18

12

Sludge concentration, g / L

24.6

Average sludge return ratio, %

130

Aeration intensity, m 3 / m 2 h

10

5

Surface load of sedimentation tank, m 3 / m 2 h

0.94

0.87

[0032] 2. The wastewater that has been ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com