Preparation method of toluenesulfonylurea

A technology of tosyl urea and p-toluene sulfonamide is used in the synthesis of important intermediates of sulfonylurea oral hypoglycemic drugs tolbutamide and gliclazide, and the preparation field of pharmaceutical intermediate p-toluene sulfonylurea, which can Solve the problems of slow progress and few reports, and achieve the effect of short reaction period, lower production cost and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

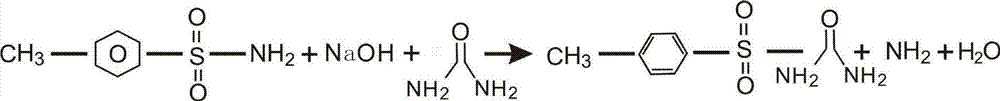

Image

Examples

Embodiment 1

[0018] Install a 1000ml three-necked bottle and a stirring oil bath heating device. Add 40 g of urea, 20 g of NaOH and 70 g of p-toluenesulfonamide in sequence, and heat up in an oil bath. Heating to above 130°C, the material is partially melted, start stirring, keep warm at 130-135°C, and react for about 100 minutes, the material liquid becomes thick enough to be unable to stir, stop stirring. Vacuum for 1 to 2 minutes to extract the ammonia gas generated by the reaction, and remove the oil bath. Add 700ml of drinking water, stir to dissolve, add 30% dilute sulfuric acid dropwise, adjust pH = 4, filter, rinse the filter cake with drinking water until pH = 5-6, discharge, crush, and dry at 100°C to obtain p-toluene Sulfonylurea 67.1g, purity 99.9%.

Embodiment 2

[0020] Install a 1000ml three-necked bottle and a stirring oil bath heating device. Add 40 g of urea, 20 g of NaOH and 70 g of p-toluenesulfonamide in sequence, and heat up in an oil bath. Heating to above 130°C, the material is partially melted, start stirring, keep warm at 135-140°C, and react for about 120 minutes, the material liquid becomes thick enough to be unable to stir, stop stirring. Vacuum for 1 to 2 minutes to extract the ammonia gas generated by the reaction, and remove the oil bath. Add 700ml of drinking water, stir to dissolve, add 30% dilute sulfuric acid dropwise, adjust pH = 4.5, filter, rinse the filter cake with drinking water until pH = 5-6, discharge, crush, and dry at 100°C to obtain p-toluene Sulfonylurea 66.9g, purity 99.0%.

Embodiment 3

[0022] Install a 1000ml three-necked bottle and a stirring oil bath heating device. Add 40 g of urea, 20 g of NaOH and 70 g of p-toluenesulfonamide in sequence, and heat up in an oil bath. Heat up to 130°C or above, the material is partially melted, start stirring, keep warm at 140-145°C, and react for about 95 minutes, the material liquid becomes thick enough to be unable to stir, stop stirring. Vacuum for 1 to 2 minutes to extract the ammonia gas generated by the reaction, and remove the oil bath. Add 700ml of drinking water, stir to dissolve, add 40% dilute sulfuric acid dropwise, adjust pH=4, filter, rinse the filter cake with drinking water until pH=5~6, discharge, crush, and dry at 100°C to obtain p-toluene Sulfonylurea 66.5g, purity 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com