Preparation method of polyaniline@polypyrrole conductive composite material

A conductive composite material, polyaniline polypyrrole technology, applied in the field of conductive composite material preparation, can solve the problems of increased product cost, a large amount of organic waste liquid, harsh experimental conditions, etc., and achieves low product cost, mild process conditions, and synthesis time. short effect

Inactive Publication Date: 2013-03-13

LANZHOU UNIVERSITY OF TECHNOLOGY

View PDF2 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(1) Electrochemical methods are used to prepare polymers. Due to the harsh experimental conditions, they are only suitable for experimental research but not for industrial production, and this method will further increase product costs;

(2) Since a large amount of organic solvents are used in this patent, a large amount of organic waste liquid will be produced after the reaction, which will cause serious environmental pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

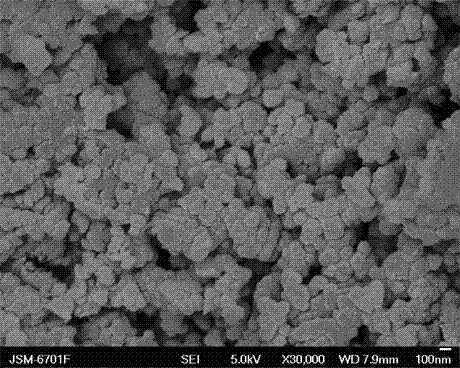

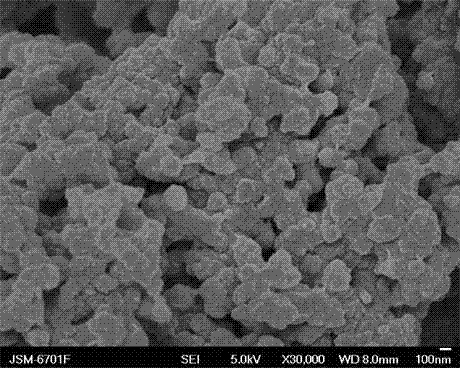

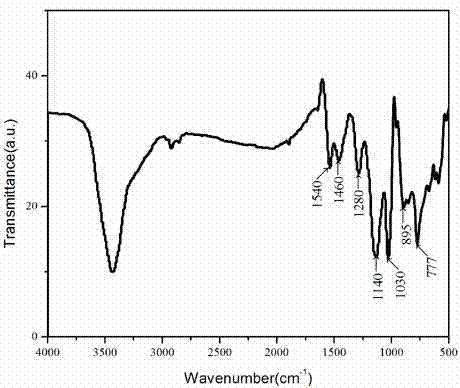

The invention discloses a preparation method of a polyaniline@polypyrrole conductive composite material, which comprises the following steps of: firstly synthesizing PAn by a chemical oxidation method, and performing leaching, cleaning and drying to obtain deep green powder of PAn; then mixing a certain amount of polyaniline with a certain amount of water by an in-situ polymerization method, adding doping agent sulfamic acid and pyrrole monomer respectively, uniformly stirring the mixed liquid, and adding an oxidant ferric trichloride; then filtering the reaction liquid, and washing until the filtrate is neutral; and finally drying the filter cake and grinding to obtain black polyaniline@polypyrrole conductive powder.

Description

technical field [0001] The invention relates to a preparation method of a conductive composite material. Background technique [0002] Conductive polymers are a new research field developed in the 1970s. Because of their unique properties, they are widely used in electrochemistry, electrode materials, optics, biotechnology, and conductive materials. Among many conductive polymers, polypyrrole exhibits good conductivity, environmental stability, photoelectricity, pyroelectricity, adjustable conductivity, easy preparation and doping due to its typical rigid conjugated large π bond structure. , can be conveniently deposited on various substrates, can be copolymerized and compounded with other functional materials, can be used at room temperature or low temperature, etc., and is widely used in sensors, electronic devices, biomedicine and other fields. Polypyrrole has the advantages of good electrical conductivity, good chemical stability, light stability and easy preparation. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L79/02C08L79/04C08G73/02C08G73/06

Inventor 冯辉霞王滨张建强刘生丽鲁华涛陈娜丽

Owner LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com