High-purity metal refining method for limiting molten zone by utilizing electromagnetic shielding

An electromagnetic shielding and melting zone technology, which is applied in the direction of improving process efficiency and energy efficiency, can solve the problems of lack of melting zone width and high-frequency electromagnetic field mutual interference, and achieve low cost, improved transmission efficiency, and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

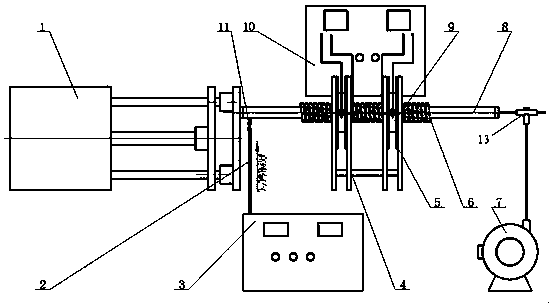

[0025] According to the regional smelting method of the present invention, high-purity indium is refined, and its specific implementation steps are:

[0026] (1) Metal indium with a purity of 4N (99.99%) obtained by industrial electrolysis is smelted and cast into a metal rod, which is placed in a quartz boat 12 with a length of 370 mm and a clean surface.

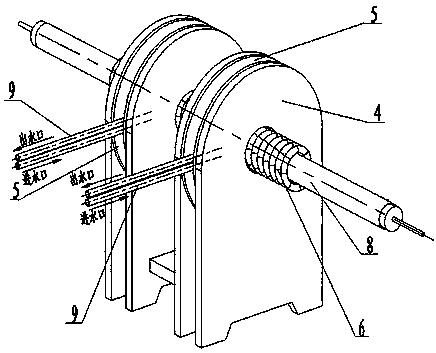

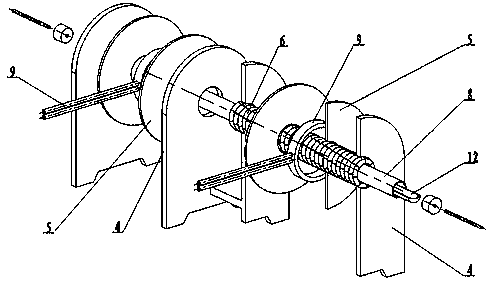

[0027] ( 2) Place the quartz boat 12 in the quartz furnace tube 8 with a length of 700mm, and seal both ends of the quartz tube with a ground seal head to form an airtight structure; the seal is connected to the vacuum pump 7 and the high-purity argon gas with a vacuum hose The purification machine 3; the quartz furnace tube 8 is equipped with a quartz spiral cooling tube 6 for heat dissipation and auxiliary melting zone control.

[0028] ( 3) Connect the graphite separator 5 and the refractory ceramic bracket 4 together, place them on both sides of the induction heating coil 9 made of copper tubes, and keep the distance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com